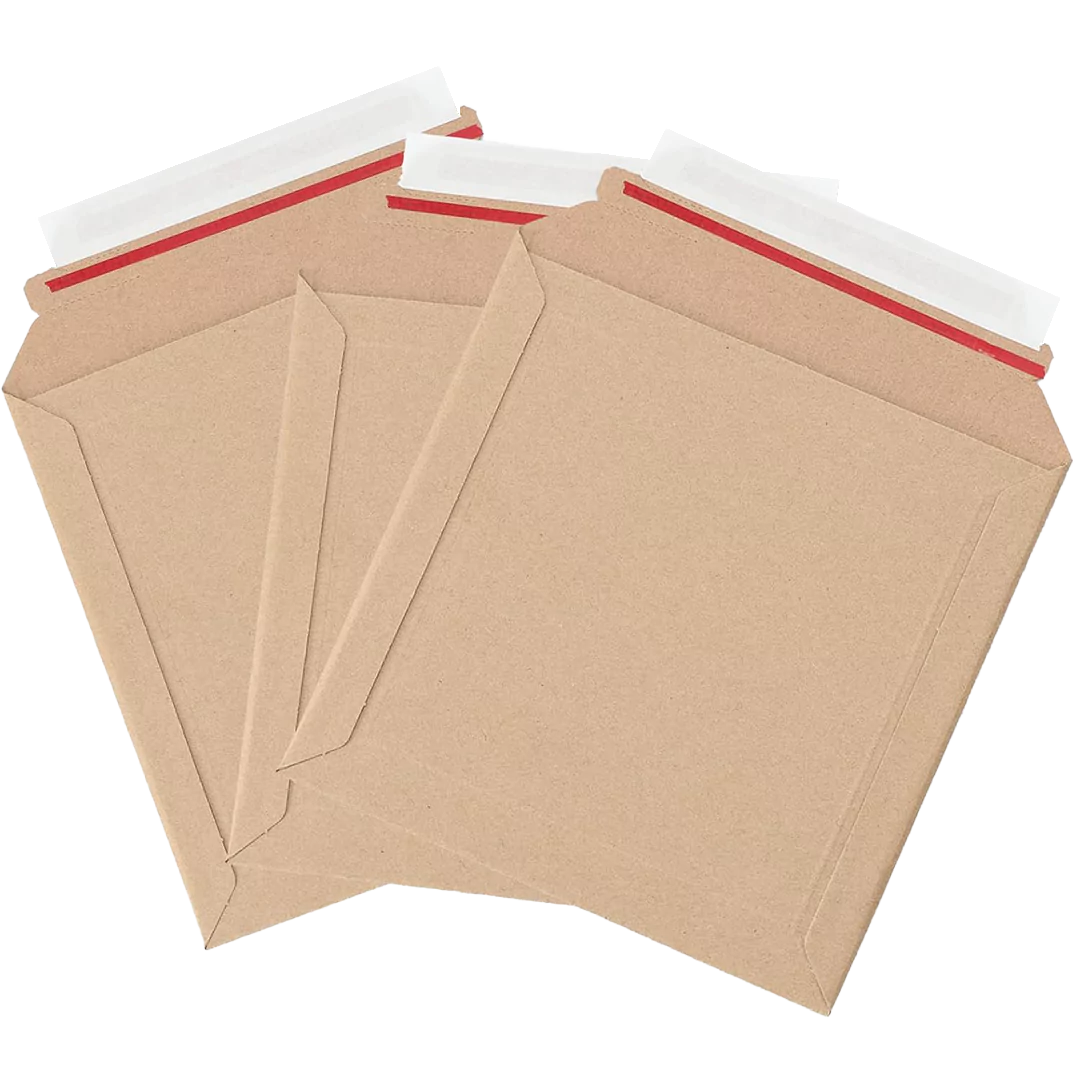

| Specification | Details |

|---|---|

| Product Name | 9×12 Window Envelopes |

| Material | High-quality paper stock (24lb, 28lb) |

| Window Size | 1-1/8″ x 4-1/2″ (Standard) |

| Window Placement | 1/2″ from left, 3/4″ from bottom |

| Envelope Dimensions | 9 inches x 12 inches |

| Seal Type | Self-seal / Gum-seal / Peel & Seal |

| Colour Options | White, Brown Kraft, Custom Colours |

| Printing Options | Offset Printing, Digital Printing, Custom Designs |

| Window Material | Transparent Poly Film |

| Use | Business documents, catalogues, booklets |

| Customization | Custom size, window shape, logo, and artwork |

| Eco-Friendly | Recyclable and biodegradable material options |

| Minimum Order Quantity | 500 units |

| Production Time | 5-7 business days |

| Shipping | Standard and expedited options available |

9×12 Window Envelopes

Custom 9×12 window envelopes are perfect for the businesses looking to send promotional material, brochures or important documents in a professional way. These envelopes have a transparent personalised size window so that the recipient’s address and specific part of the document could be visible without opening the envelope. The product boxes UK offers custom printed window envelopes for direct mail and marketing material.

You can easily personalise these envelopes to reflect the brand’s identity. No matter if you want contact details, design or the company’s logo, our advanced printing options have great flexibility to create something unique. Durable material ensures sustainability and security and transparent clear paper 9×12 window display help to show the address, information. So, if you want a professional solution for mailing needs, for get custom envelopes london 138 eswyn rd place your order today and get custom size envelopes uk to elevate the overall brand’s presence.

Starting From: £0.10 Per Box

Available in Stock

Q. What materials are used for 9×12 Window Envelopes?

Q. What is the size of the window on the 9×12 envelopes?

Q. Are the 9×12 Window Envelopes eco-friendly?

Q. Can I customise the design of the 9×12 Window Envelopes?

Q. What types of sealing options are available for the 9×12 Window Envelopes?

Q. What are the uses of 9×12 Window Envelopes?

Q. Do you provide printing options for the 9×12 Window Envelopes?

Q. What is the minimum order quantity for 9×12 Window Envelopes?

Q. How long does it take to produce the 9×12 Window Envelopes?

Q. Are the 9×12 Window Envelopes strong enough to protect important documents?

Q. Can I order eco-friendly kraft 9×12 Window Envelopes?

Q. Do you offer samples of the 9×12 Window Envelopes before ordering in bulk?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.