| Type | Specification |

|---|---|

| Material | Multi-layer Mylar (PET/VMPET/PE or PET/AL/PE) |

| Barrier Properties | Odour-proof, moisture-proof, UV-resistant, oxygen-resistant |

| Closure | Resealable zip lock, heat sealable top |

| Printing Options | Gravure, digital, or offset printing up to 10 colours |

| Finishing | Glossy, matte, soft-touch, holographic, metallic, or spot UV |

| Custom Logo | Yes – full custom logo with CMYK or PMS colours |

| Colour Options | Customisable – black, white, silver, gold, clear, rainbow, or fully printed |

| Available Sizes | 1g, 3.5g, 7g, 14g, 28g, 1oz, 2oz, 8oz, 16oz, custom sizes available |

| Thickness | 3 mil, 3.5 mil, 4 mil, 5 mil, or customised |

| Custom Shape | Yes – stand-up pouch, flat pouch, gusseted, die-cut |

| Window Option | Optional clear, frosted, or shaped window |

| Smell Proof | Yes – certified odour control barrier technology |

| Quantity | Minimum 500 units – bulk orders available |

| Usage | Herbs, spices, edibles, snacks, CBD, coffee, supplements |

| Eco-Friendly Options | PLA, kraft-laminated mylar, recyclable or compostable variants |

| Certifications | FDA compliant, BPA free, food-grade, child-resistant (optional) |

Smell Proof Mylar Bags

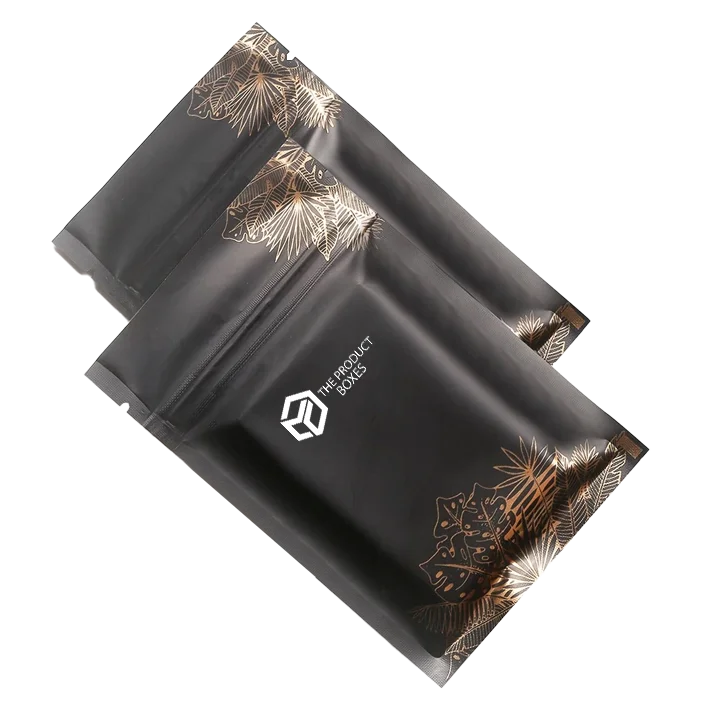

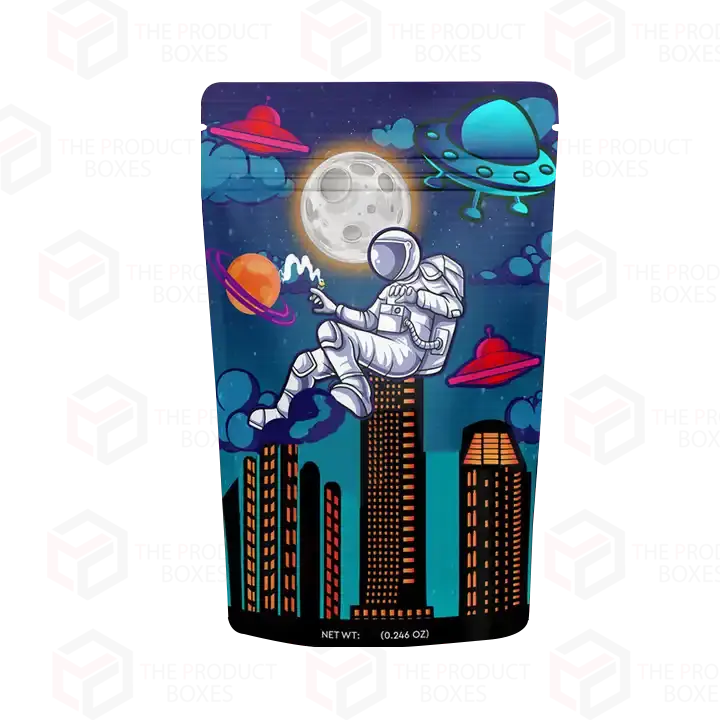

The Product Boxes UK offer smell proof Mylar bags to provide protection with preservation for your products. High-barrier smell proof bags are designed specifically to preserve herbs, edibles, coffee items, teas and spices that retain full scent containment. Made from premium multi-layered Mylar material, our smell proof bags stay durable with moisture proof protection. Our bags feature puncture resistance while properly storing your contents. The Product Boxes UK allow the customers to get custom size foil bags with your corporate logo, detailed product information and finish options to get striking packaging which can enhance your brand reputation on retail displays.

Zipper mylar bags are available across various size ranges with flat bags, stand-up pouches and zippers along with matte, gloss and metallic finish options. These are suitable for retail and wholesale use. So, if you’re still looking for the best place to buy mylar bags wholesale. TPB is here for you with complete custom design support. Contact us now to get smell proof Mylar bags which provide a combination of product freshness and packaging security with premium branding features.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Smell Proof Mylar Bags?

Q. Are Smell Proof Mylar Bags effective for blocking odours?

Q. Can I customise the design of my Smell Proof Mylar Bags?

Q. Are these bags suitable for food and consumables?

Q. Do these bags support resealing?

Q. Are eco-friendly options available for Smell Proof Mylar Bags?

Q. Do you offer branding features like logos and colours?

Q. What sizes are available for these bags?

Q. Are these bags moisture and UV-resistant?

Q. What is the minimum order quantity for custom Mylar Bags?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.