| Type | Specification |

|---|---|

| Material | Food-Grade Kraft, Greaseproof or Wax-Coated Paper |

| GSM Options | Custom 24–50 GSM (Common: 28, 30, 36 GSM) |

| Sheet Sizes | Standard & Custom – 10×10″, 12×12″, 14×14″, A3, A4 |

| Print Type | CMYK, PMS Spot Colour, or Flexo up to 4 Colours |

| Logo Printing | Edge-to-Edge, Centralised, Full-Repeat Custom Logo |

| Colour Base | White, Natural Brown Kraft, or Dyed Paper |

| Coating Options | Wax Coated, PE Coated, or Uncoated Greaseproof |

| Grease Resistance | Custom Kit Level 3–7 – Ideal for Hot & Oily Sandwiches |

| Texture | Smooth Matte, Slightly Textured Kraft, or Gloss Waxed |

| Cut Format | Flat Sheets, Perforated Rolls, Die-Cut Sandwich Wrap |

| Food Compatibility | Sandwiches, Subs, Wraps, Burgers, Paninis, Bagels |

| Microwave Safe | Yes – With Heat-Stable Ink and Paper Selection |

| Refrigerator Use | Yes – With PE/Wax Coated Barrier Paper |

| MOQ | 1,000 Sheets for Printed – Lower for Plain Kraft |

| Biodegradability | Compostable, Recyclable, and Plastic-Free Options |

| Certifications | FDA Approved, ISO 22000, FSC Certified Material |

| Ink Type | Water-Based, Non-Toxic, Oil & Food Safe Inks |

| Packing Style | Reamed, Shrink-Wrapped, or Kraft-Wrapped Bundles |

| Roll Options | Branded or Plain Rolls – Widths Up to 900mm |

| Sampling | Free Custom Branded Sample Sheet Available |

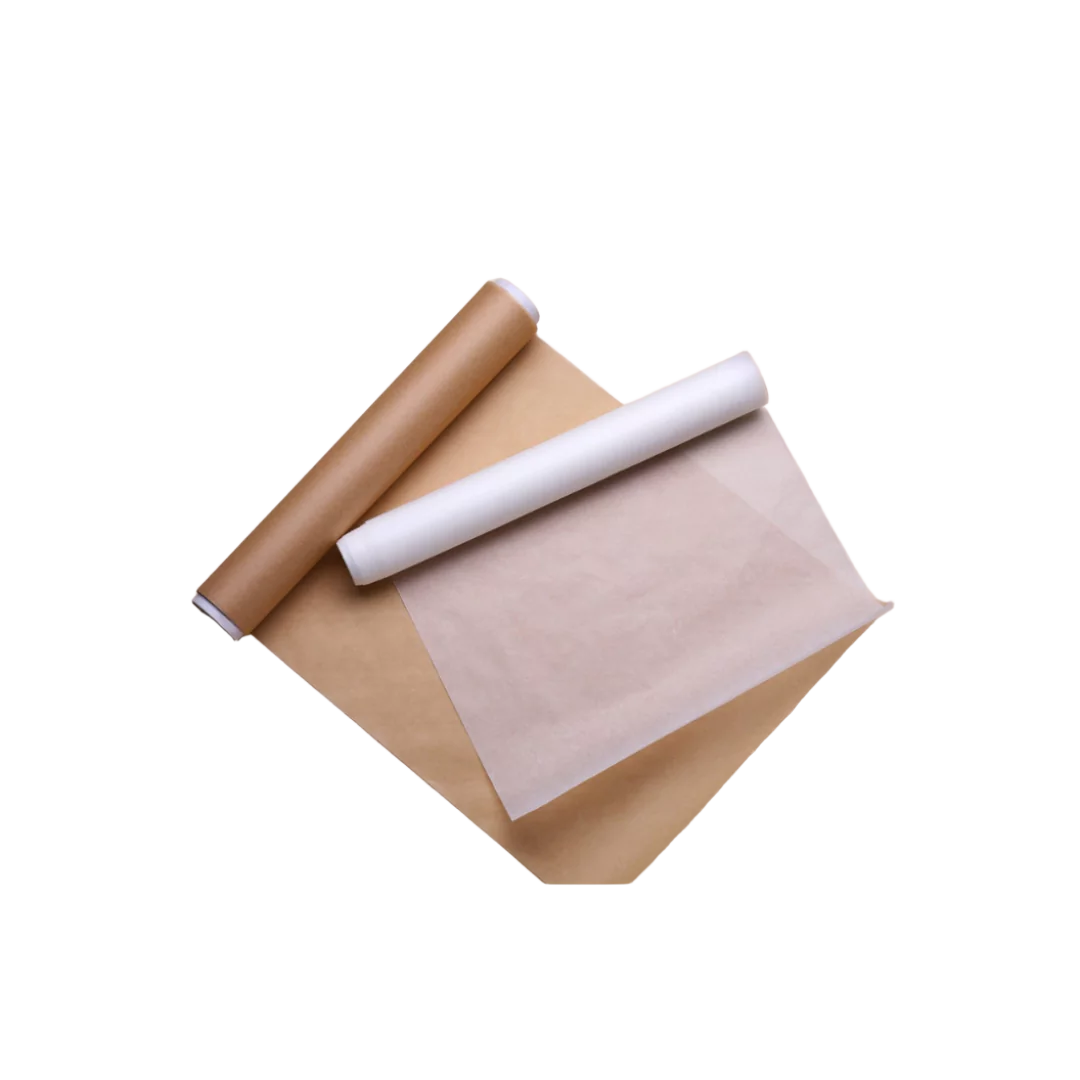

Sandwich Wrapping Paper

Keep sandwiches fresh, secure, and professionally presented with our specialized sandwich wrapping paper designed for busy food service operations. Unlike ordinary paper, our wrapping sheets feature optimal thickness that prevents soggy bottoms while allowing easy folding and secure closure. Deli counters, sandwich shops, and corporate catering services rely on this essential packaging solution daily. Smart design includes tear-resistant properties that handle loaded subs, pressed paninis, and delicate croissant sandwiches without splitting.

The moisture barrier protects ingredients while maintaining bread texture during transport and storage. Available in classic white for clean presentation or kraft brown for artisanal appeal. Food wrapping paper with logo turn every wrapped sandwich into mobile advertising, displaying your logo prominently while customers carry meals throughout their day. Wholesale quantities offer significant savings for high-volume establishments, while bulk packaging reduces reordering frequency. At, The Product Boxes UK Premium quality meets affordable pricing, making professional sandwich presentation accessible for startups and established businesses alike.

Starting From: £0.50 Per Box

Available in Stock

Q. What’s the best material for wrapping hot or grilled sandwiches?

Q. Does sandwich wrap paper prevent sogginess from sauces or condiments?

Q. Can sandwich wrapping paper be used for both dine-in and takeaway?

Q. What sizes are commonly used for sandwich wrapping sheets?

Q. Can sandwich wraps be custom printed with branding?

Q. Is sandwich wrapping paper microwave safe?

Q. What’s the difference between dry wax and wet wax sandwich paper?

Q. Is sandwich paper compostable or recyclable?

Q. Will wrapping sandwiches in paper affect their temperature during delivery?

Q. Can sandwich wrapping paper be used as liner for trays or baskets?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.