| Type | Specification |

|---|---|

| Product Name | Blank Cigarette Boxes |

| Material Options | High-density SBS board, white cardboard, kraft stock, or soft-touch paperboard |

| Material Thickness | 250–400 GSM depending on cigarette count and rigidity requirement |

| Box Style | Flip-top lid, tuck-end, or slide-out sleeve configuration |

| Finish Type | Gloss, matte, soft-touch, or UV-coated smooth surface |

| Colour Options | Plain white, natural kraft, or custom solid colour tones |

| Logo Printing | Foil-stamped, embossed, or digitally printed branding zones |

| Printing Process | CMYK, PMS, metallic ink, or holographic foil with 1200 DPI resolution |

| Printing Area | Full-wrap exterior surface and optional inner liner artwork |

| Coating Options | Anti-scratch, moisture-resistant, or heat-seal compatible coating |

| Inner Liner | Silver foil, gold foil, or paper inner wrap for tobacco freshness |

| Size Variants | Standard king-size, 100s, slim, or custom dimensions |

| Capacity | 10, 20, or 25-stick configurations; custom count available |

| Adhesive Type | Heat-resistant, food-safe glue with precision die-cut flaps |

| Box Shape | Rectangular rigid form with square-edge alignment |

| Structural Reinforcement | Double wall or reinforced lid for product compression stability |

| Printing Area | Front, back, sides, and top lid available for full branding coverage |

| Optional Add-ons | Embossed logo, foil edge detailing, or security hologram |

| Eco Standard | FSC® certified board and eco-safe soy-based inks |

| Finish Accuracy | ±0.2 mm tolerance with precision die-cutting |

| Packaging Type | Delivered flat-packed or pre-glued, ready for assembly |

| Customisation | Logo, colour, material, and size fully tailored to brand or market |

| Quantity Range | Low MOQ from 100 units to bulk production runs up to 100,000+ |

| Surface Treatment | Varnish, lamination, or aqueous coat for added durability |

| Usage | Ideal for tobacco products, herbal cigarettes, or promotional packaging |

| Compliance | Meets EU and UK packaging standards for cigarette boxes |

| Lead Time | 8–12 business days post artwork confirmation |

| Custom Offer | Personalised designs, finishes, and branding available on demand |

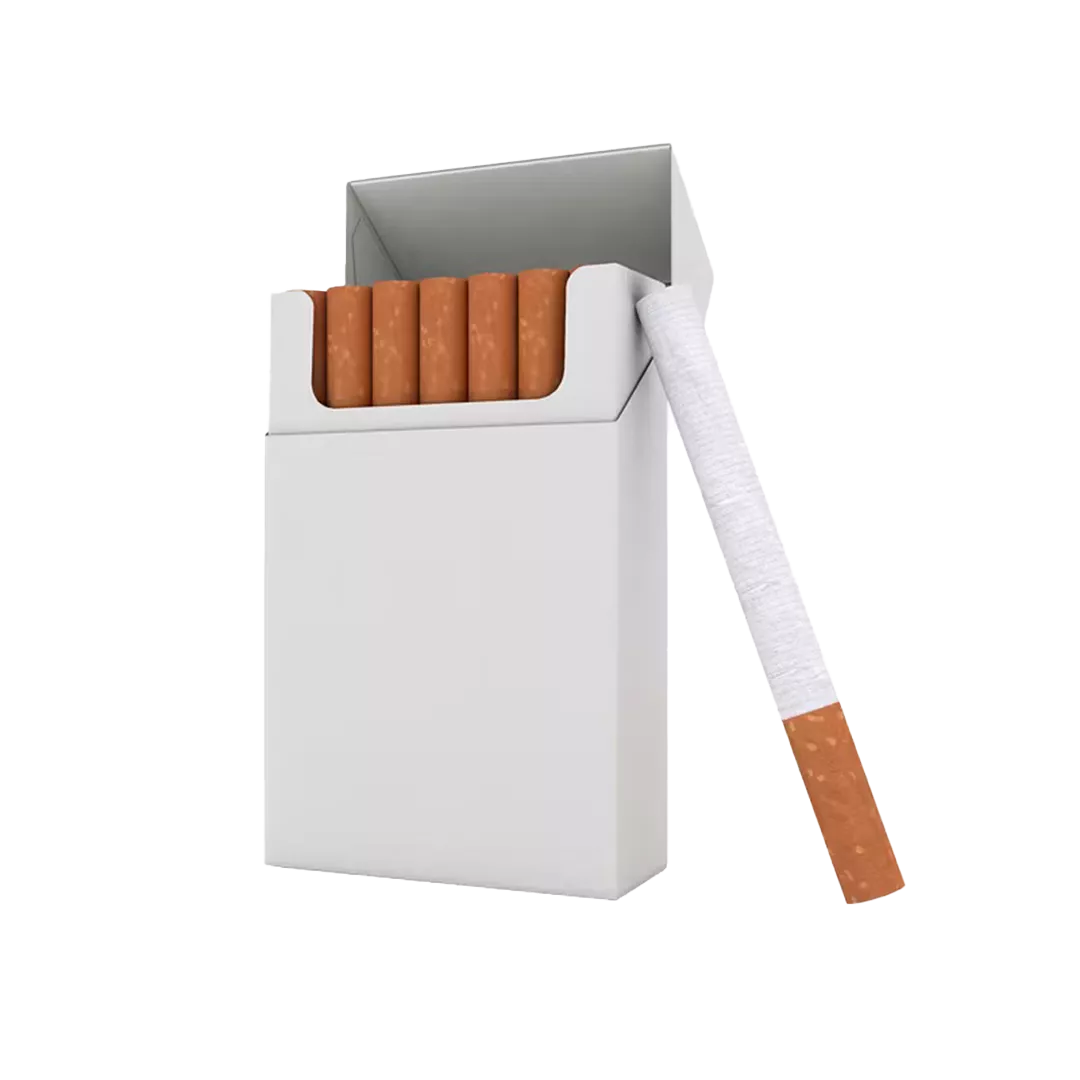

Blank Cigarette Boxes

Source blank cigarette boxes for tobacco retailers, rolling paper companies, or businesses needing flip-top packaging for small products. These hinged-lid boxes replicate the classic cigarette pack format with sturdy cardboard construction and smooth opening mechanisms that customers recognize instantly. The flip-top design features a hinged lid that stays attached while opening, preventing loss and providing easy one-handed access. Interior dimensions accommodate standard cigarette sizing, but creative businesses also use this format for packaging pre-rolled items, herbal cigarettes, incense sticks, or even non-tobacco products like candies and small cosmetics. Blank surfaces accept custom printing, labels, or stamps for branding and regulatory compliance information.

Available in white cardboard or kraft brown, both options provide excellent printing surfaces for logos, product information, health warnings, and design elements. The compact rectangular shape fits comfortably in pockets and purses while the rigid construction protects contents from crushing. Cellophane wrapping compatibility allows for sealed packaging when required. The Product Boxes manufactures flip-top box packaging in various sizes for tobacco retailers and businesses requiring cigarette-style packaging formats. Wholesale pricing available on bulk orders with or without custom printing services for regulatory labeling needs.

Starting From: £0.33 Per Box

Available in Stock

Q: What makes blank cigarette boxes useful for brand customization?

Q: Which board thickness is best for durable cigarette box construction?

Q: Can blank cigarette boxes be supplied with inner foil lining?

Q: Are blank cigarette boxes suitable for both king-size and slim cigarettes?

Q: How do blank boxes help meet local packaging compliance requirements?

Q: Can blank cigarette boxes be used for hand-rolled or specialty tobacco products?

Q: What finishing options can be applied after purchase?

Q: Are blank cigarette boxes shipped flat for storage efficiency?

Q: How well do these boxes hold up during shipping and retail handling?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.