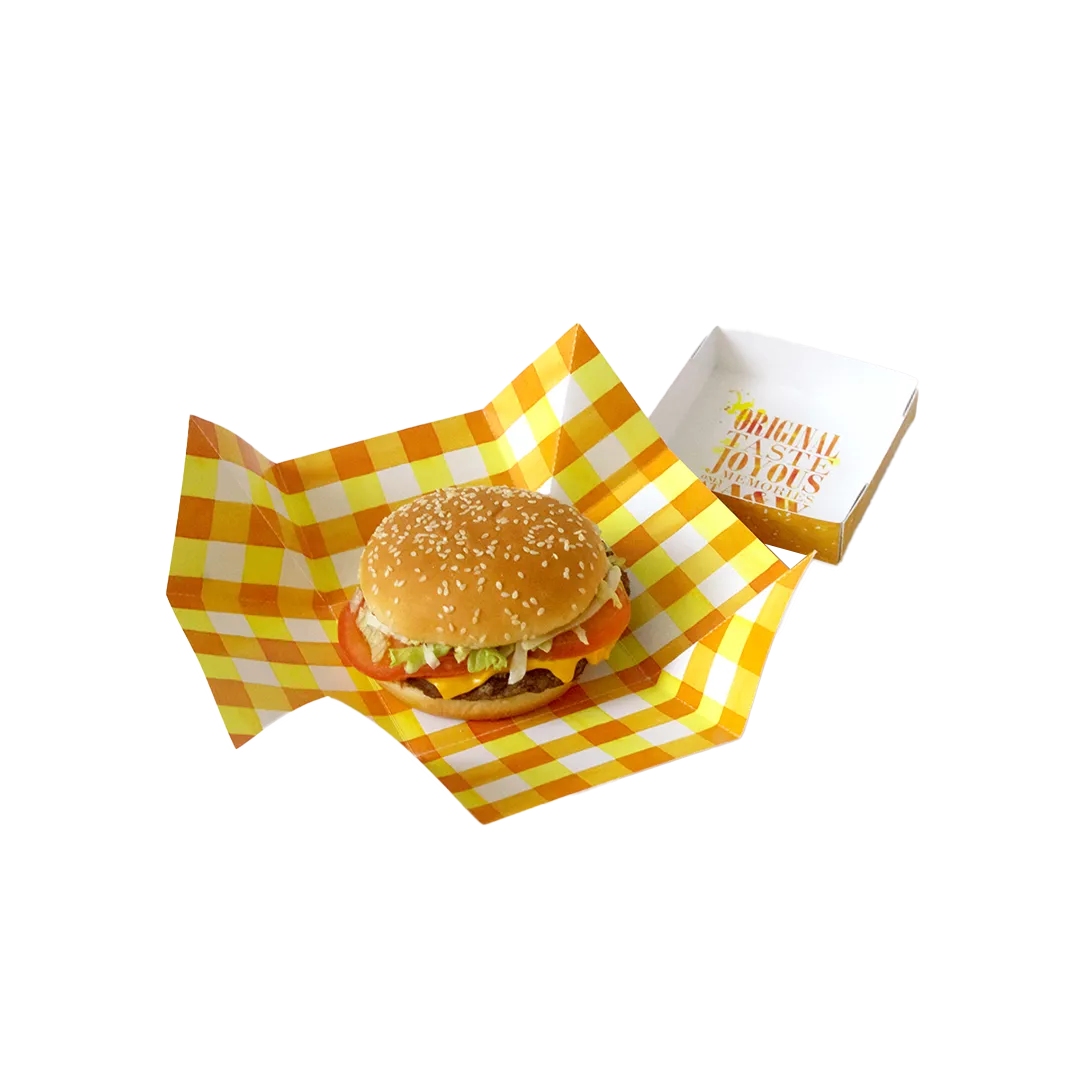

Premium Custom Printed Burger Wrapping Paper for Your Business

Presentation is as significant in the foodservice business as the product. That’s why The Product Boxes UK provides the high quality wrapping of burger paper that would help to improve the appearance of your food products and give it functional advantages as well. Our wrapping paper is available in different sizes, designs, and our clients have an opportunity to make their own printing which is perfect to match your brand and business. It doesn’t matter whether you have a fast-food restaurant, a gourmet burger restaurant or a food truck, we have the ideal wrapping paper.

Different Uses of Wrapping Paper

Wrapping paper is a flexible packaging solution that is applied in the foodservice sector. It is a popular wrapping to be used on burgers, sandwiches, wraps, hot dogs, and even fries so that food can be kept fresh and presentable. Wrapping papers are used by many restaurants and food trucks in lining serving baskets and trays, which is an added hygiene and aesthetic. It is also perfect in takeaway and grab-and-go packaging and doesn’t leak grease and makes it easier to handle by customers. Branding and marketing Custom printed wrapping paper is an effective way of promoting the logo, message, and identity of the business with each order.

Greaseproof Paper Sheets for Fast Food Packaging to Keep Your Meals Neat and Clean

The Product Boxes UK realises that food safety is one of the major concerns. This is the reason our branded food paper is made of food-safe materials so that it is safe to wrap your food products. It is also safe, but our wrapping paper is grease proof, so you can wrap burgers, sandwiches and other greasy food with no fear of any leaks or mess. It is of high standards, a protective barrier, which allows to maintain the freshness and taste of your products and guarantee your customers receive a good experience in each instance.

Burger Wrap Paper Sizes: Choose the Perfect Fit for Your Needs

We have different burger wrap paper sizes to suit your special needs. The following table can assist you to select the most appropriate size to your business:

| Size | Dimensions | Ideal For |

| Small | 10″ x 10″ | Perfect for single burgers |

| Medium | 12″ x 12″ | Ideal for medium-sized burgers |

| Large | 14″ x 14″ | Great for larger gourmet burgers |

| Extra Large | 16″ x 16″ | Perfect for oversized burgers and meals |

Explore Our Range of Wrapping Paper Options

We provide a wide range of wrapping paper types to suit different needs. Choose from:

- Wax Food Paper

- Grease-Proof Paper

- Parchment Paper

- Printed Custom Paper

Upgrade Your Packaging with Our Premium Paper Styles

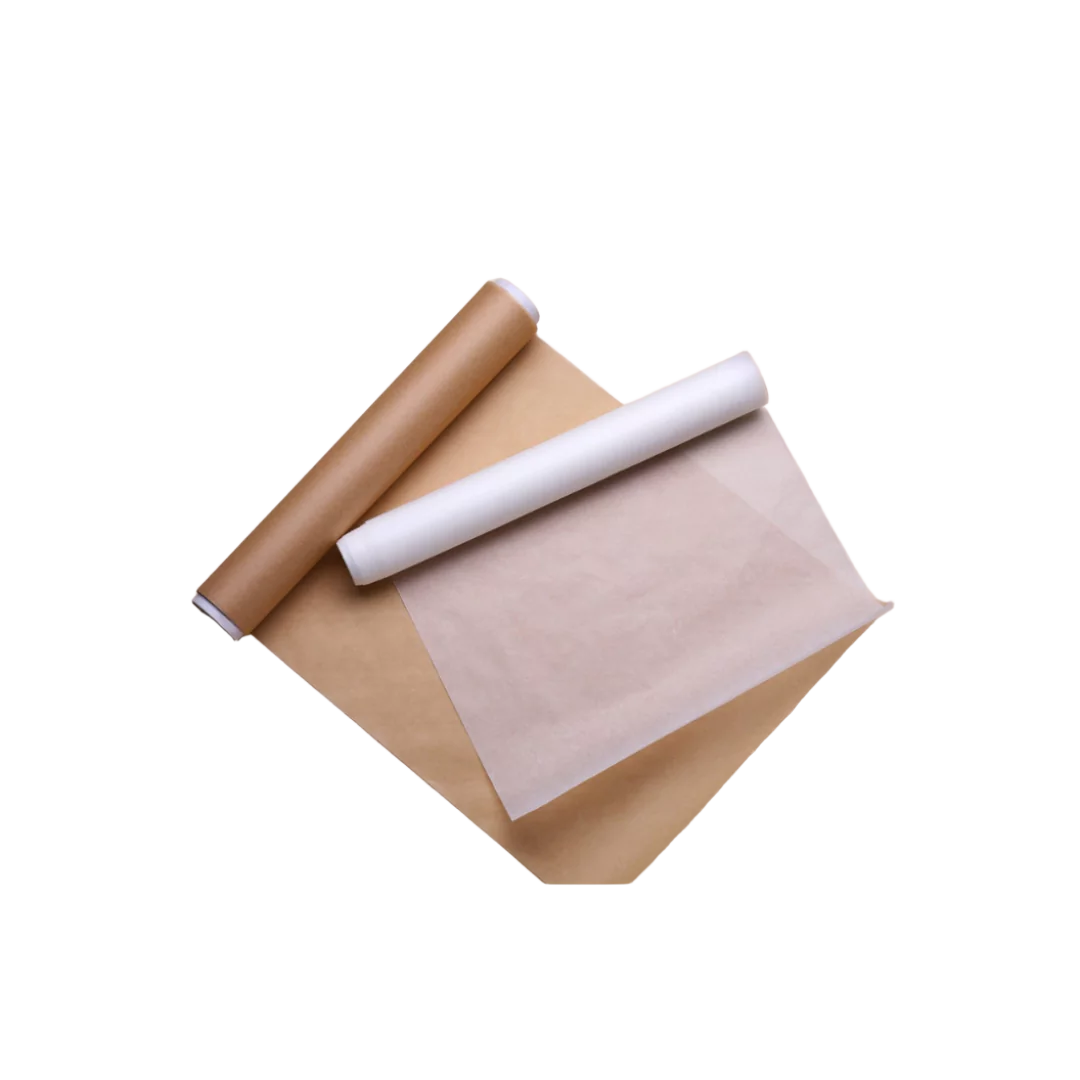

We offer a variety of styles to fit your business needs, including:

- Sheets

- Rolls

- Pop-Up Sheets

No matter the style, we ensure that our wrapping paper is durable, functional, and stylish for every business.

Order Wrapping Paper Sheets in Bulk at Unbeatable Wholesale Prices

Confused about where to buy food wrap paper? The Product Boxes UK offers competitive wholesale pricing for businesses looking to purchase large quantities of custom burger packaging. It doesn’t only save money in the long-term, but bulk orders also make sure that you have wrapping paper whenever you need it. You will find there are flexible bulk ordering options to suit any large restaurant chain or the small independent food vendor. Wholesale pricing will provide your business with the possibility of scaling and keeping its costs low.