Burger Boxes

What are Burger Boxes?

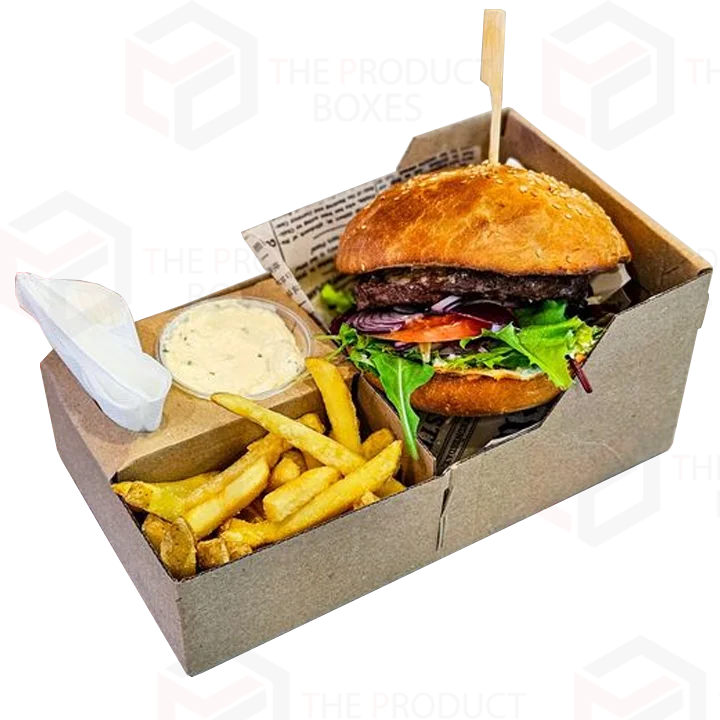

Burger boxes are used to place burgers. These boxes maintain the quality of burgers. Moreover, they protect the burgers from any damage or contamination during transit.

Packaging Materials for Burger Boxes

Packaging materials play a pivotal role in the durability and longevity of custom burger boxes. They give an aesthetic look to packaging boxes. The final look of boxes depends on it.

Here are some of the materials we offer:

- Corrugated Material

- Cardstock Material

- Kraft Material

- Rigid Material

Corrugated Material

Corrugated boxes are made of corrugated paperboard. It ensures the durability of burger packaging boxes because they are lightweight and thicker than ordinary boxes. It keeps the product secure during shipping and handling.

Cardstock Material

Personalised burger boxes are made of heavyweight cardstock. These boxes are elegant and have a glossy finish. Moreover, it is highly customisable and offers several designs.

Kraft Material

Kraft burger boxes are made of brown kraft material. This material is easily recyclable and used to minimise waste.

Rigid Material

These black burger boxes are made of thick and rigid paperboard. These boxes can easily be customised. It is available in various colours, sizes, shapes, and add-ons.

Burger Boxes Wholesale

Burger boxes wholesale are in high demand because every product in the market needs packaging. It is necessary to pack them in packaging to give them an enticing look. The issue is where to buy burger boxes wholesale. Put your hands on The Product Boxes UK. We offer these boxes with free delivery. You can save your cost and enhance your profit ratio.

Colour Combination for Burger Boxes Wholesale

Colours play a central role in making sales. People consider the colours while purchasing a product. They have a substantial impact on customers’ minds. Colours have the potential to turn your customers into loyal buyers. These colour shades can make your burger packaging attractive and worth buying with the touch of a few shades. Moreover, if your loved one loves to eat burgers, you can give them burgers packed in boxes with a fantastic colour combination.

We have the two main colour models, have a look at them:

- CMYK Colour Model

- PMS Colour Model

CMYK Colour Model

Cyan, Magenta, yellow, and Key (black) are this model’s leading and only colours. The colours are mixed to create new shades. If you are sure about the colour and it is part of this model, go for it. The quality will also not disappoint you. You will not get an exact colour match in this model. Moreover, it is easy to make immediate changes in this model. Remember! This model is inexpensive.

PMS Colour Model

Are you not satisfied with the CMYK colour model? If yes, the PMS Colour Model is a perfect option for you to go. Pantone Matching System contains several colour options. You do not need to worry about finite choices. You will have results better than the CMYK model. Furthermore, it is expensive too. It is suitable for high-volume orders.

Coating Options for Black Burger Boxes

Along with the colour model, the coating is an important feature to add to your packaging. Every part we mention is of great importance. We must fulfill your packaging requirement. Let us make your burger tray with premium-quality printing.

We offer the following coating types at The Product Boxes:

Matte Coating

This type of coating provides extra shine to your packaging. It does not reflect in the sunlight but doesn’t stop it from highlighting the prominent features of your personalised burger boxes.

Gloss Coating

Contrary to matte coating, it shines highly in the sunlight. It reflects in the sunlight and shows your eco-friendly burger boxes glittery and lustrous texture.

Extra Features – Fascinating Cardboard Burger Boxes

Don’t you like plain burger boxes? Well, we also. Why do you go for the simple box when we are here to make it exciting and superb for you? Do you know how? By adding extra features. The Product Boxes UK team is expert and highly acknowledged for its talent and skills. We are prone to challenges and always feel happy to work on them. you can also renovate your custom packaging boxes into a revenue-generating tool for your business. We are here to help you with the add-ons.

Therefore, we offer the options:

- Embossing

- Debossing

- Spot UV

- Window Patching

- Hot Stamping

Embossing

Embossing is a process to add highlighting effects to your cardboard burger boxes. When you emboss on the packaging, It makes your product highlight and allures your customers. Ultimately, it leads to more sales.

Debossing

Debossing is the opposite of embossing. It will adds depressing effects to your black burger boxes. It will entice your customers.

Spot UV

It is the process of adding extra shine to your custom burger boxes. It is a great way to add an aesthetic look to your products. Moreover, you can get glossy effects and make your product stand out. Your product will be distinguished from your competitors’ products.

Window Patching

It is the process of adding thin film and windows. With the help of this window, customers can view the product without opening the packaging. They do not need to open the boxes. You can allure your customers with mini burger boxes. As a result, you will get high sales.

Hot Stamping

Along with window patching, we offer hot stamping. It is the process of adding imprints on the packaging. In this way, the burger tray is adorned in a better fashion. Moreover, it gives an enticing look to these boxes.

Premium Quality Printing to Make Your Eco-Friendly Burger Boxes Aesthetic

Printing is a perfect marketing tool. It tells a lot about your product. It acts as a source of communication between the brand and its consumers. You can add logos and other product information to create custom-printed burger boxes. It will help your customers to understand what ingredients are used in the product.

The Product Boxes offer the following Printing Techniques:

- Digital Printing Technique

- Offset Printing Technique

- Screen Printing Technique

Digital Printing Technique

Digital Printing is a highly used technique. In this technique, we use digital files for printing purposes. You should go for digital printing if you have a low range of custom-printed burger boxes. Remember! It is easy to make immediate changes in this technique.

Offset Printing Technique

Do you want more than the digital printing technique? If yes, the offset printing technique is a perfect option for you to go. In this process, we use rubber plates for printing. Moreover, it is suitable for high-mass orders. In addition, it is expensive too.

Screen Printing Technique

It is the third type of printing. Mesh is used for printing in the screen printing technique.

Prototypes for Our Valued Customers

Generally, people become worried about the final appearance of kraft burger boxes. We offer prototypes to our valued customers. You have the option to place your orders after your satisfaction.

The Prototypes we offer are:

- 2D View

- 3D Inspection

- Physical Sampling (Provides on Request)

Conclusion

We are the top leading manufacturer of custom food boxes in the UK. We offer these boxes in various shapes, sizes, designs, and materials. You can contact us any time. We are here to serve you with the best burger boxes. We accept minimum order of 100 pieces. Furthermore, we offer free shipping and design. Place your order now!

Get an instant quote

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.