| Type | Specification |

|---|---|

| Material | Premium vinyl, PET film, kraft paper, or polypropylene, 80–150 microns |

| Printing | Digital CMYK, UV printing, solvent and eco-solvent inks, Pantone matching |

| Adhesive | Permanent acrylic, removable, or repositionable adhesives (custom options available) |

| Back Liner | Silicone-coated glassine or PET release liner with optional logo print |

| Finish | Glossy, Matte, Satin, UV Coated, Anti-Scratch, Soft-Touch, Holographic |

| Custom Logo | Available – Embossed, Debossed, Foil Stamped, Spot UV |

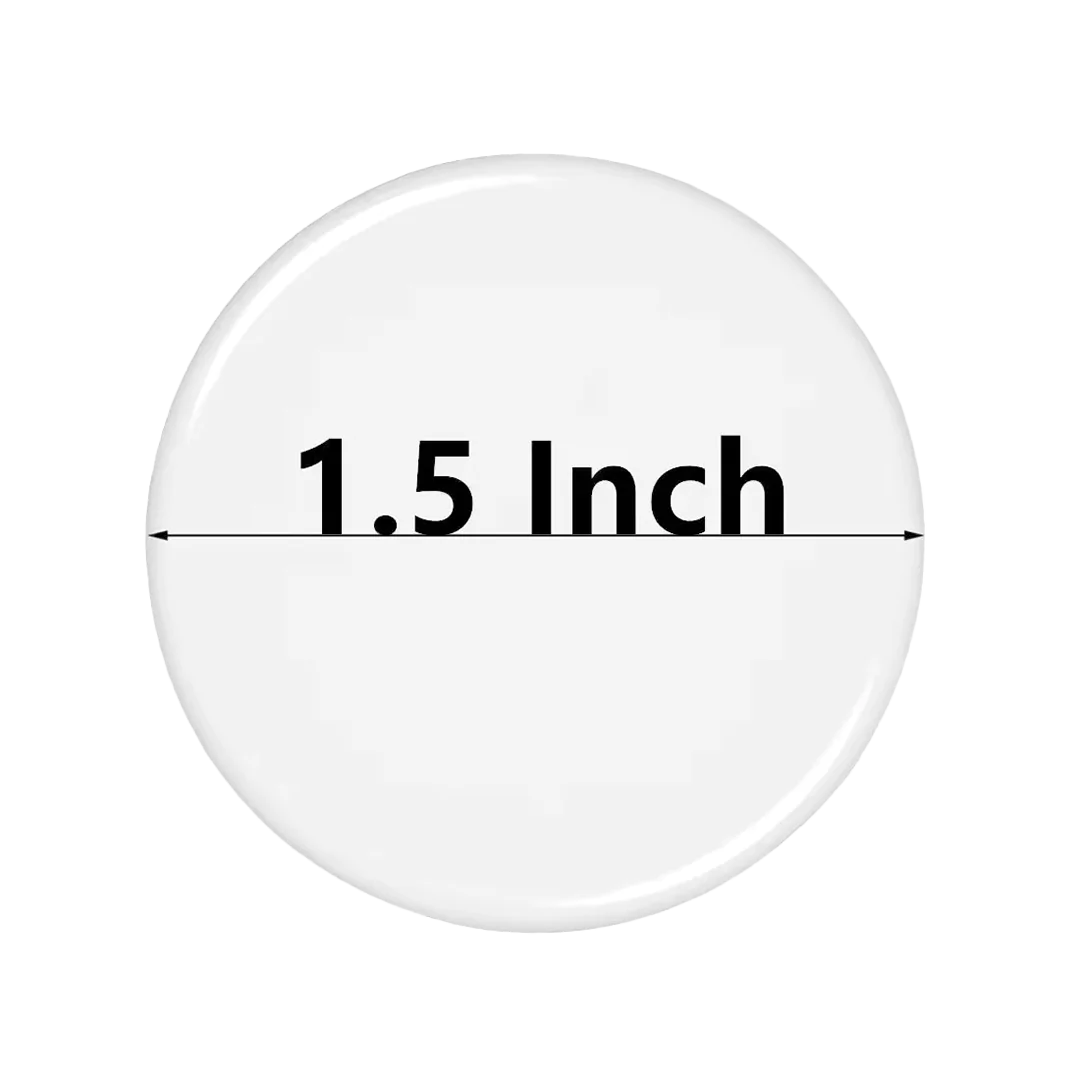

| Shape | Round (1.5″) standard; also available in custom die-cut shapes |

| Size | Standard 1.5 inch diameter; custom sizes from 0.5″ to 5″ on request |

| Thickness | 0.08mm to 0.15mm depending on material and finish |

| Quantity | Minimum order 50 pieces; bulk and wholesale options available |

| Durability | Waterproof, UV resistant, oil-resistant, scratch-proof for indoor/outdoor use |

| Usage | Product labeling, brand seals, jars, candles, packaging, envelope seals |

| Customization | Custom artwork upload, colour match, text, effects, shape and branding |

| Packaging | Delivered in rolls, sheets, or individually cut; optional custom packaging available |

| Eco Options | Recyclable vinyl, compostable kraft paper, water-based inks, eco adhesives |

| Lead Time | 5–10 business days standard; express production on request |

1.5 Inch Round Stickers

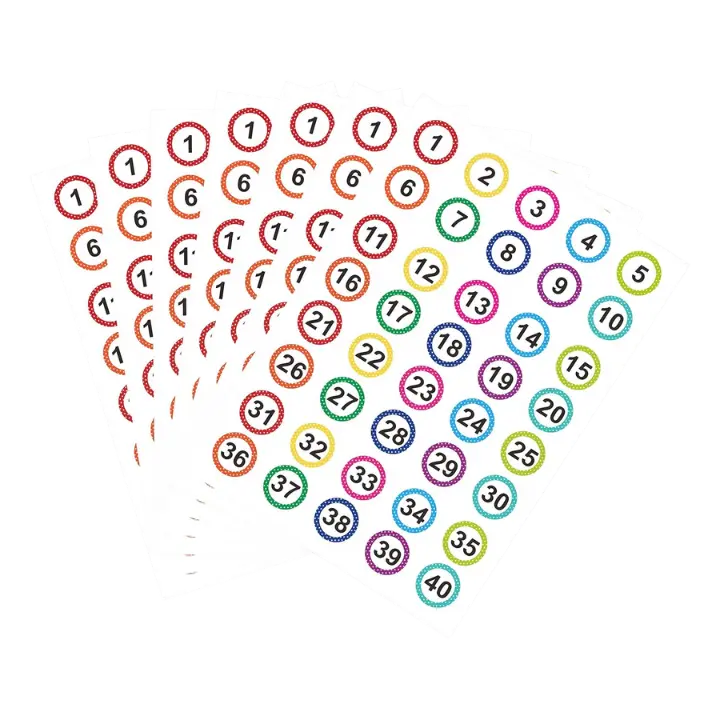

Customise your packaging, branding or event giveaways by using 1.5 inch round stickers from The Product Boxes UK. You can use these tiny stickers to seal jars, add labels to things, decorate favour bags or give a touch of professionalism to thank-you cards and envelopes. Pick from glossy, matte or transparent finishes for our stickers and they also come with waterproof and oil-resistant coats for various uses. We can handle any type of print job you require such as logo stickers, ingredients labels or other graphics and ensure everything looks sharp and colourful.

We allows you to choose between permanent and removable adhesive backing for each sticker. Whether you’re making a company logo or sticking to a DIY project, our small round logo stickers come in both minimum order and bulk orders for your convenience. The Product Boxes UK provides exact printing on stickers, fitting your brand and the look of your packaging. Get in touch today to begin with made with love stickers that highlight every point.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make 1.5 inch round stickers?

Q. Are the stickers waterproof and weather-resistant?

Q. Can I customise the design of my round stickers?

Q. What adhesive options are available for these stickers?

Q. What finishes can I choose for my stickers?

Q. What is the minimum order quantity for 1.5 inch stickers?

Q. Are eco-friendly materials available for sticker production?

Q. What is the average production and delivery time?

Q. Can I order stickers in rolls, sheets, or individual pieces?

Q. Are these stickers suitable for product labeling?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.