| Type | Specification |

|---|---|

| Material | Premium vinyl, PET film, or coated paper, 80–120 microns |

| Printing | Digital CMYK, Screen Printing, UV Offset, Spot UV available |

| Adhesive | Permanent Acrylic, Removable, Repositionable (custom options) |

| Back Liner | Glassine paper or PET release liner with optional logo print |

| Finish | Glossy, Matte, Satin, UV Coated, Anti-Scratch, or Soft-Touch |

| Custom Logo | Available – Embossed, Debossed, Foil Stamped, UV Spot |

| Shape | Star shape standard; custom die-cut shapes available |

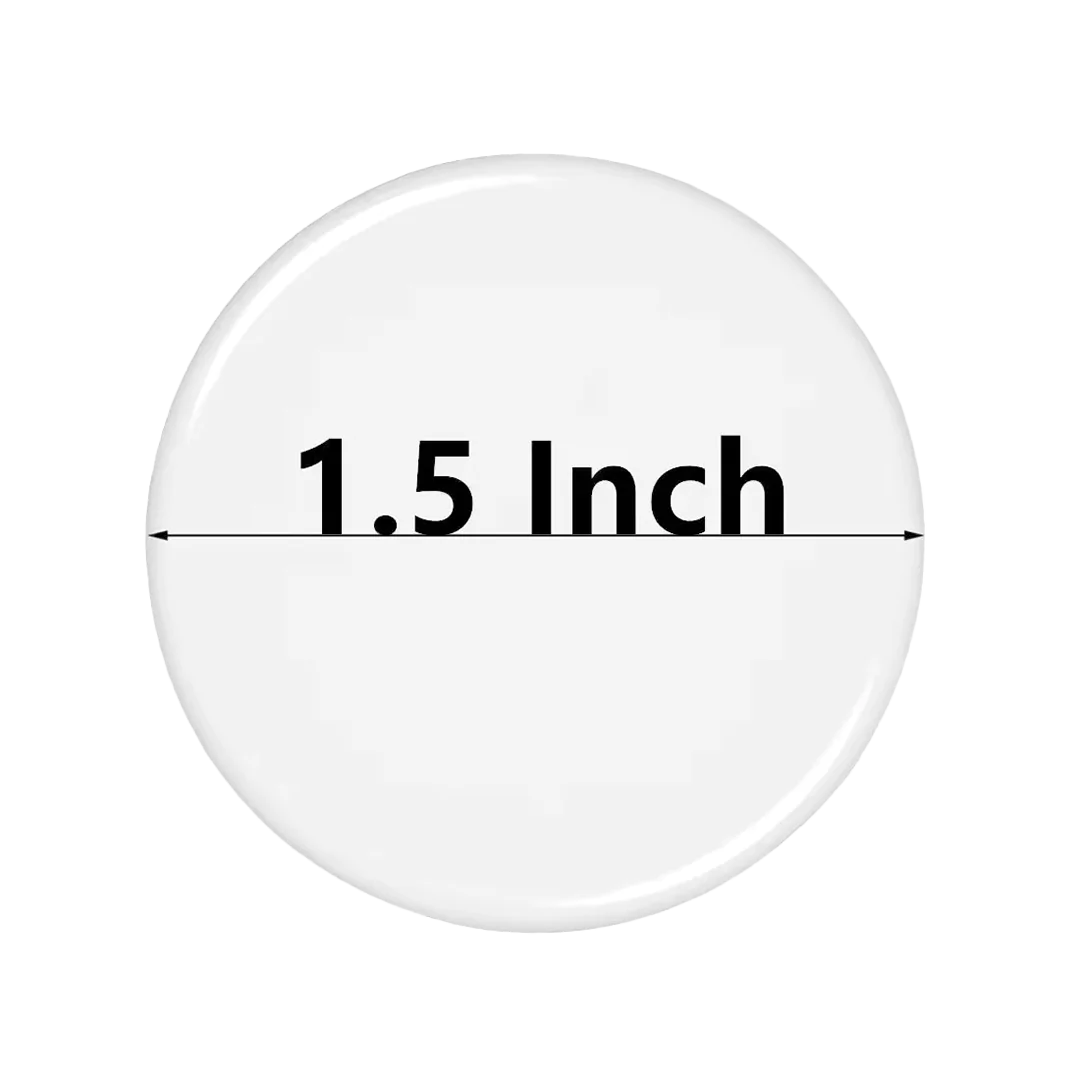

| Size | Standard 2″ diameter; fully custom sizes from 1″ to 5″ or more |

| Thickness | 0.1mm to 0.3mm depending on material and finish |

| Quantity | Minimum order 50 pieces; bulk and wholesale options available |

| Durability | Waterproof, UV resistant, scratch-resistant for indoor/outdoor use |

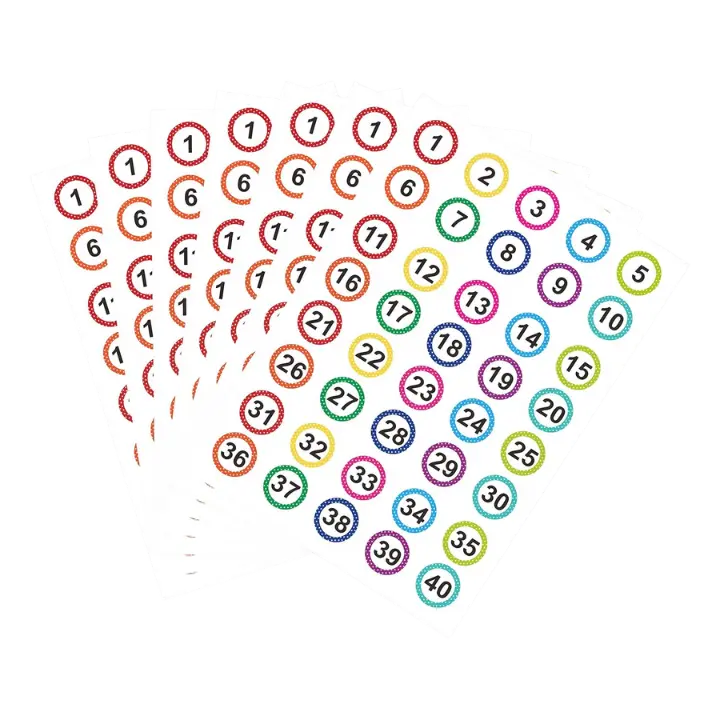

| Usage | Product labeling, promotions, branding, giveaways, merchandise |

| Customization | Full customization: artwork upload, color matching, text, and effects |

| Packaging | Available in sheets, rolls, individual packs; custom branded packaging |

| Eco Options | Recyclable materials, eco-friendly inks, water-based adhesives available |

| Lead Time | 7–12 business days; expedited options on request |

2 Inch Star Stickers

Give your decoration a unique and creative look with 2 inch star stickers provided by The Product Boxes UK. You can use these stickers to add decoration to planners, scrapbooks, treats for parties, packing or classroom rewards. They are made with strong adhesive vinyl or paper, they adhere tightly and can be removed without leaving any leftover marks. Feel free to use bold colours, shiny surfaces, glittered edges or even include your logo or a message on your star stickers.

If you plan to use them to decorate packages, for special seasons or as arts and crafts, our custom die cut stickers are the right balance of small and eye-catching. Customers can expect full customisation from TPB, quick production and the option to buy in bulk for any need they have. Enjoy creating with our custom stickers which are crafted to have both appealing choices and great quality.

Starting From: £0.25 Per Box

Available in Stock

Q. What materials are used to make 2 inch star stickers?

Q. Can I customise the design, colours, and shape of 2 inch star stickers?

Q. Are 2 inch star stickers waterproof and suitable for outdoor use?

Q. What types of adhesives are available for 2 inch star stickers?

Q. What finishes can I select for 2 inch star stickers?

Q. What is the minimum order quantity for custom 2 inch star stickers?

Q. Can I add custom logos or text to the star stickers?

Q. Are custom sizes available for star-shaped stickers?

Q. Are eco-friendly materials used in these stickers?

Q. How long is the production time for 2 inch star stickers?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.