| Type | Specification |

|---|---|

| Material Options | Corrugated cardboard, kraft board, SBS paperboard, rigid chipboard |

| Wall Type | Single-wall, double-wall, triple-wall corrugated board |

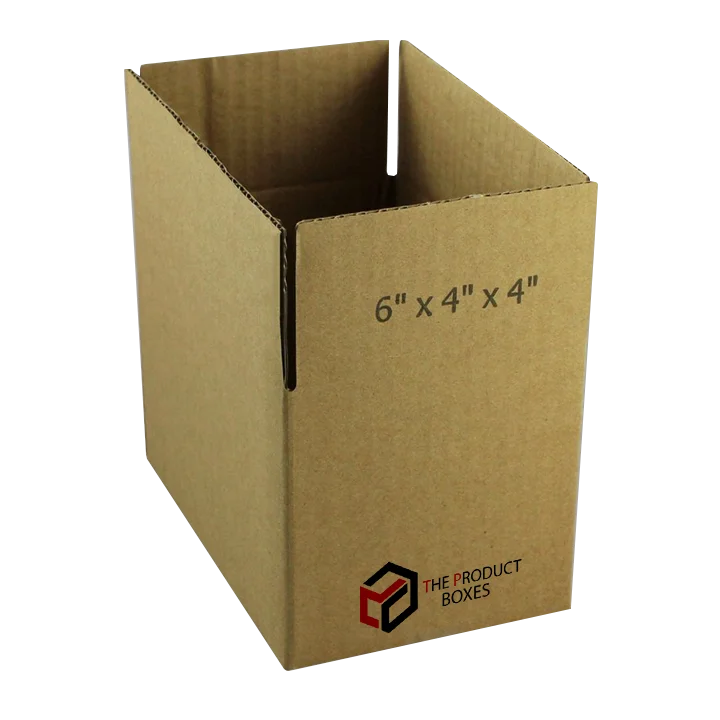

| Size Range | Custom-fit for 250ml to 2L bottles, cans, and multipacks |

| Box Styles | Regular slotted container (RSC), full overlap (FOL), die-cut, tuck-top auto bottom |

| Weight Capacity | Up to 20kg depending on material thickness and flute grade |

| Color Options | Natural brown, white, full-colour CMYK, or PMS-matched tones |

| Logo & Branding | Custom printing, embossing, debossing, foil stamping, spot UV |

| Insert Types | Die-cut cardboard inserts, molded pulp, foam, or PET trays |

| Coating Options | Aqueous, gloss, matte, soft-touch lamination, water-resistant coating |

| Closure Options | Glue flap, tape seal, tab-lock, or self-locking structure |

| Eco Options | 100% recycled paper, biodegradable board, soy-based ink |

| Quantity Range | Available from low-volume short runs to bulk wholesale orders |

| Printing Methods | Offset, flexographic, screen, or digital print |

| Compliance | FDA-grade material, RoHS-compliant inks, FSC-certified stock |

| Use Cases | Bottle shipping, craft beer packaging, wine logistics, juice and soda deliveries |

| Custom Features | QR codes, barcode printing, handling icons, temperature indicators |

Beverage Shipping Boxes

Get beverage shipping boxes to ensure bottled and canned drinks are not damaged during shipping over different distances. We offer strong packaging at The Product Boxes UK, so you can promote your brand safely. Built from strong corrugated cardboard, these boxes include dividers inside to stop items from shifting and breaking as they are delivered. For shipping wine, juices, energy drinks or specialty sodas, our boxes secure and protect your products. You can use custom printing on the outside of your packaging to display your company logo, instructions and overall brand look which helps build trust with customers.

Order our product shipping boxes in several sizes and arrangements for single as well as multiple goods. Such drinks are suitable for eCommerce operations, wholesale buyers or companies that deliver drinks. Contact us for reliable and branded shipping boxes which protect your beverages and improve how your products get opened.

Starting From: £1 Per Box

Available in Stock

Q. What materials are used to make Beverage Shipping Boxes?

Q. Are these boxes strong enough for glass bottles and cans?

Q. Can I customise the size and configuration of the shipping boxes?

Q. Do these boxes come with dividers or inserts?

Q. Can I print my brand or logo on the shipping boxes?

Q. Are beverage shipping boxes water-resistant?

Q. Are these boxes eco-friendly and recyclable?

Q. What box styles are available for beverage shipping?

Q. What is the minimum order quantity for custom beverage shipping boxes?

Q. How long does it take to produce and ship these boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.