| Type | Specification |

|---|---|

| Material | E-flute / B-flute corrugated board with black kraft or premium white liner |

| Color | Standard matte black / custom Pantone colours available on request |

| Sizes | Fully customisable; standard options include 6x4x2″, 8x6x3″, and 10x8x4″ |

| Logo | Custom logo printing in digital, offset, or flexo with foil, embossing, or spot UV |

| Printing | CMYK / PMS colour printing, inside-outside print optional |

| Finish | Matte, gloss, soft-touch lamination, or aqueous coating |

| Inserts | Optional foam, kraft, or corrugated inserts; die-cut available |

| Quantity | Minimum 50 units; bulk order options with scalable production |

| Eco Options | Recycled board, soy-based inks, FSC® certified materials |

| Use Case | Ideal for eCommerce, retail shipping, promotional kits, and influencer boxes |

| Turnaround Time | Standard 7–12 business days; rush service available upon request |

| Closure Style | Dust flaps and front tuck for secure seal during transit |

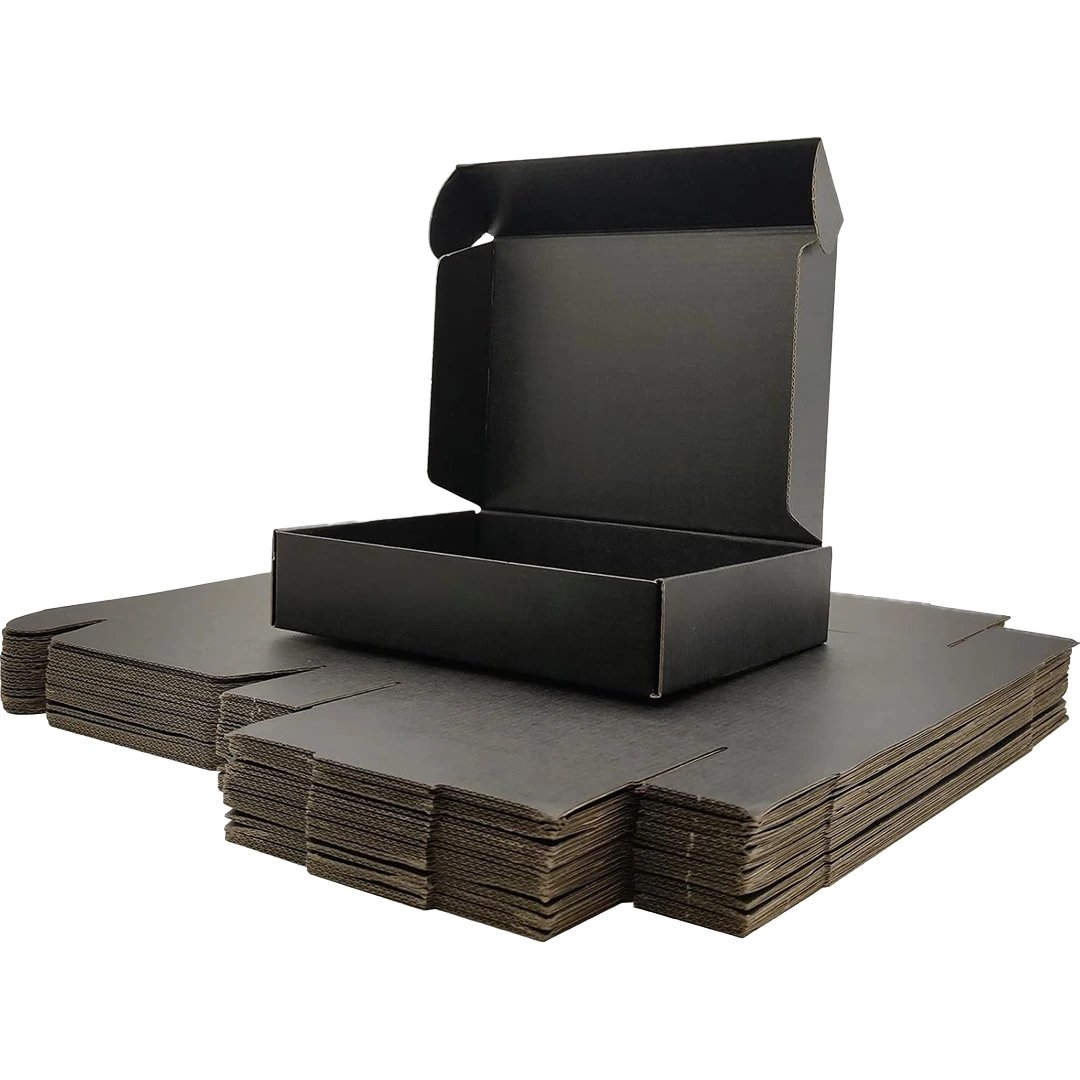

Black Corrugated Mailer Boxes

Black corrugated mailer boxes by The Product Boxes UK are appreciated by online retailers, shops and subscription box companies because they are not only pleasing to look at, but protect products well, too. Made with strong corrugated cardboard, these boxes provide great protection and cushioning for your items while they are being shipped. The selected dark black gives an extra touch of style and style to your company’s products which is enhanced by adding your brand logo, tagline or artwork with custom printing. You can use mailer boxes to ship clothing, cosmetics, tech accessories and similar items, giving customers an enjoyable unboxing.

By simply putting them together and using optional inserts, we ensures you can have mailer boxes that are both useful and fashionable. Consumers can select from small, medium or large sizes and different finishes such as matte and gloss lamination, knowing the materials are sustainable. Ordering a small number of boxes or for blank mailer boxes wholesale shipments is no problem, as The Product boxes UK will customise your shipments to match your brand.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Black Corrugated Mailer Boxes?

Q. Are Black Corrugated Mailer Boxes available in custom sizes?

Q. Can I print my logo or branding on these boxes?

Q. Are Black Corrugated Mailer Boxes eco-friendly?

Q. What finishes are available for these boxes?

Q. Can I get internal printing or inserts with the mailer boxes?

Q. Are these mailer boxes strong enough for shipping?

Q. What is the minimum order quantity?

Q. How long does it take to produce Black Corrugated Mailer Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.