| Type | Specification |

|---|---|

| Product Name | Bottle Boxes with Dividers |

| Material Options | Corrugated cardboard, Kraft board, or premium SBS paperboard |

| Board Grade | 350–800 GSM or E/B-flute corrugation depending on bottle weight |

| Divider Type | Interlocking die-cut inserts, fixed or removable partitions |

| Divider Material | Same-grade board or reinforced corrugated linerboard |

| Printing Process | CMYK offset, flexo, digital, or Pantone spot printing |

| Logo & Branding | Foil-stamp, UV spot, emboss, deboss, or digital imprint |

| Colour Options | Natural Kraft, white coated, or full custom Pantone-matched colours |

| Finish Options | Gloss, matte, soft-touch, or anti-scuff lamination |

| Coating Options | Aqueous, UV, or moisture-resistant coating for added protection |

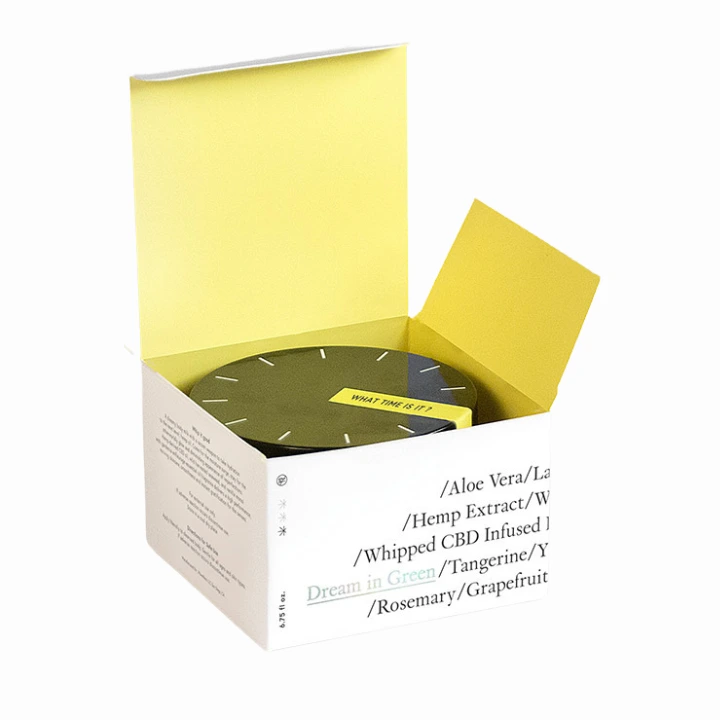

| Structure Design | Top-lid, tuck-end, magnetic closure, or mailer-style construction |

| Size Range | Custom-fit for single, 2, 3, 6, or 12 bottle configurations |

| Weight Capacity | Up to 12 kg per box depending on material grade |

| Edge Type | Precision die-cut with folded, glued, or stitched seams |

| Internal Fit | Engineered to prevent bottle collision and absorb vibration |

| Window Option | Clear PET, PLA, or acetate display window (optional) |

| Inserts Customisation | Adjustable dividers, foam or paperboard cushioning inserts |

| Eco Certification | FSC® certified, recyclable, biodegradable materials |

| Printing Resolution | Up to 1200 DPI for detailed logos and label alignment |

| Adhesive Type | Water-based or hot-melt food-safe bonding |

| Temperature Resistance | -10°C to +60°C for storage and transport safety |

| Stackability | Reinforced fluting for load-bearing and pallet storage |

| Assembly | Flat-packed, pre-glued, or manual interlock setup |

| Quantity Range | Low MOQ 100 units up to 100,000+ bulk runs |

| Usage | Ideal for wine, spirits, sauces, essential oils, or glass bottles |

| Surface Texture | Smooth matte, linen emboss, or leather-textured coating |

| Customisation Options | Size, print, logo, divider type, and colour fully customisable |

| Safety Compliance | Meets ISO 9001 and ASTM D642 packaging strength standards |

| Lead Time | 7–12 working days after design confirmation |

| Shipping Format | Flat-packed for space efficiency and safe bulk delivery |

| Country of Manufacture | Made in the UK using sustainable board and inks |

Bottle Boxes With Dividers

Ship glass bottles safely with bottle boxes with dividers built-in featuring . that prevent breakage and costly product losses. Whether you’re shipping wine, craft beer, olive oil, hot sauce, or cosmetic bottles, proper separation during transit isn’t optional—it’s essential for protecting your products and maintaining customer satisfaction. Our bottle boxes come with sturdy cardboard dividers that create individual compartments for each bottle, eliminating glass-on-glass contact that causes chips and breaks. The dividers slide into place quickly, making packing efficient even during high-volume shipping days. Available in configurations for 4, 6, 12, or custom bottle counts depending on your product line and shipping needs.

Beverage companies, gourmet food producers, and beauty brands trust these boxes because they reduce damage claims and refund requests significantly. The corrugated construction absorbs shocks while dividers keep contents stationary. Add custom printing with your company logo, handling instructions, or “Fragile” warnings to ensure careful treatment throughout delivery. The Product Boxes UK supplies specialized packaging including beverage shipping boxes, beer bottle carriers, mason jar boxes, and glassware packaging for businesses shipping breakable products. Available in various sizes to fit standard and custom bottle dimensions. Wholesale pricing supports wineries, breweries, and artisan producers.

Starting From: £1 Per Box

Available in Stock

Q: What purpose do dividers serve in bottle boxes?

Q: What materials are used for bottle box dividers?

Q: Can dividers be adjusted for different bottle diameters?

Q: How many bottles can a box with dividers typically hold?

Q: What cardboard strength is ideal for heavy or glass bottles?

Q: Can bottle boxes with dividers be branded or printed?

Q: Are these divider boxes suitable for liquid or temperature-sensitive bottles?

Q: Can inserts or padding be combined with dividers for extra safety?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.