| Type | Specification |

|---|---|

| Material | Rigid cardboard, duplex board, kraft, or corrugated fibreboard |

| Structure | Two-piece box, magnetic closure, drawer-style, or lid & base style |

| Custom Sizes | Fully customisable – standard size starts from 150x150x50mm |

| Printing | Offset, digital, screen printing available with CMYK or PMS |

| Finishing | Gloss/matte lamination, soft-touch, UV spot, foil stamping |

| Logo | Embossed, debossed, foil printed, or UV spot custom branding |

| Colour Options | Fully custom colour palette, single-tone or gradient design |

| Insert Options | Foam insert, silk fabric lining, die-cut cardboard support |

| Closure Styles | Magnetic lid, ribbon tie, tuck-in flap, or slide-in drawer |

| MOQ | Minimum order quantity starts from 100 pieces |

| Lead Time | 7 to 10 business days after design confirmation |

| Eco Options | Recyclable kraft paper, soy-based inks, and FSC-certified board |

| Usage | Lingerie retail, e-commerce delivery, or gift box sets |

| Samples | Plain or fully printed sample boxes available upon request |

Bra Box Packaging

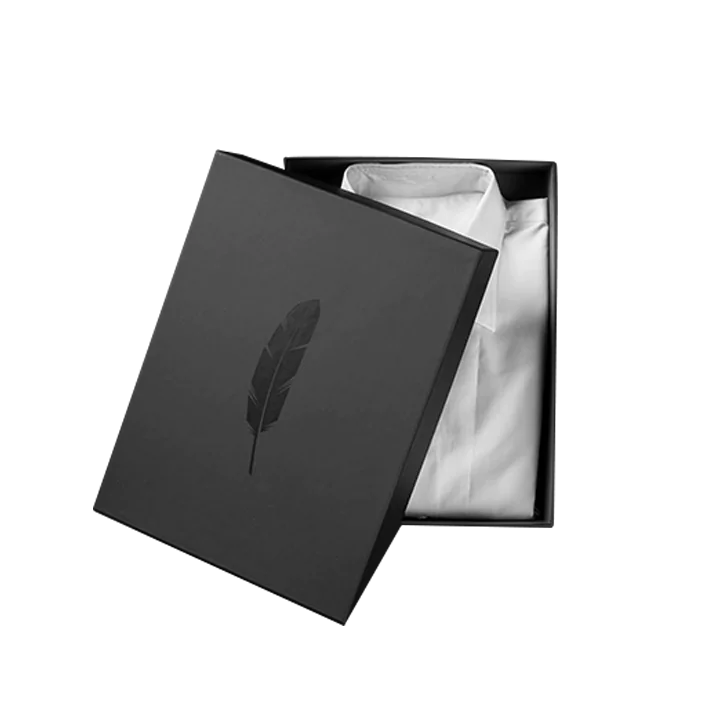

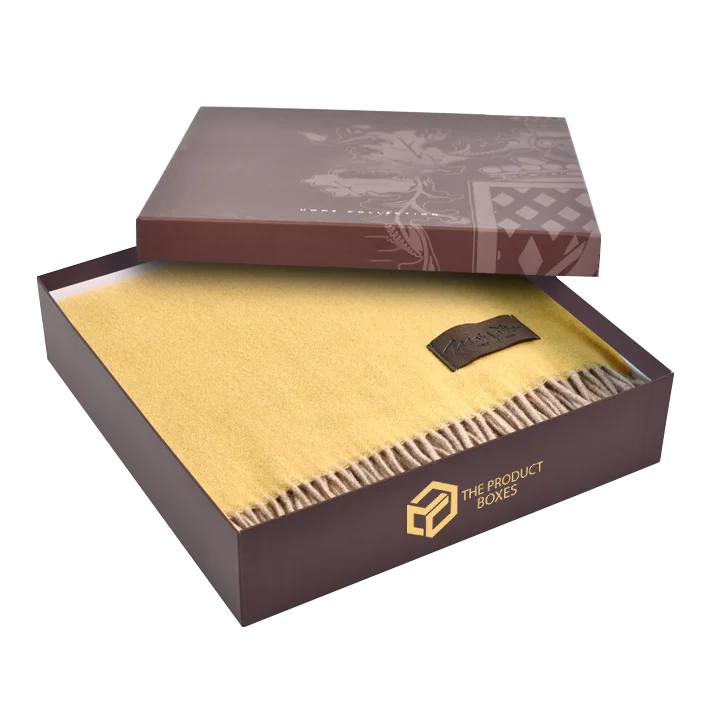

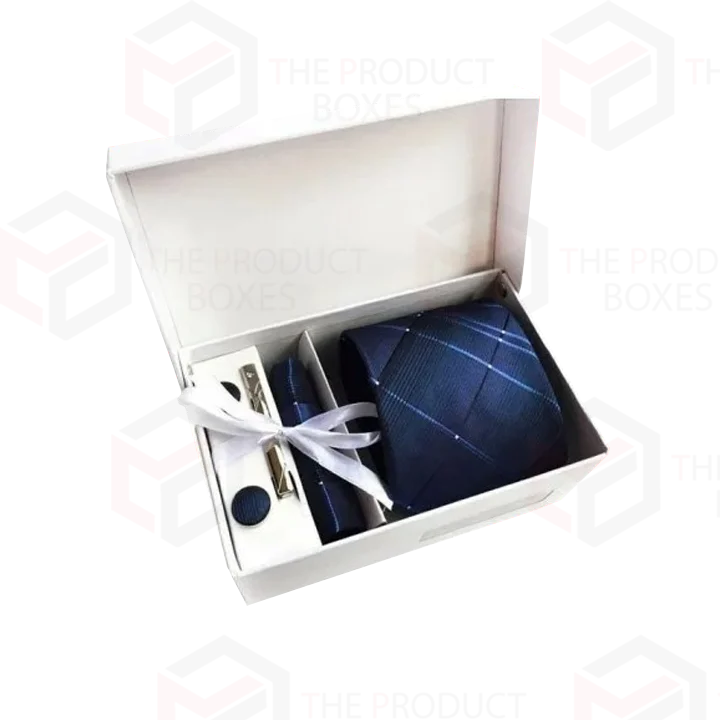

We are here to design custom bra box packaging with exclusive and endless printing options, sizes, box styling, and finishing options. These options help to make a lasting first impression on assails and passersby. Add to this a bra box packaging that we create that fits all bra products.

That means we are here for you whether you need simple and classy lingerie boxes or luxurious bra box packaging with custom options. On the other hand, when your audience is ladies, it is essential to create out-of-ordinary appeal boxes wholesale. So, we are here to make your lingerie boxes look appealing and well-designed that clearly communicate the size, colour, shape, style and quality of the product inside.

Starting From: £0.80 Per Box

Available in Stock

Q. What materials are used to make Bra Box Packaging?

Q. Can I customise the size and shape of Bra Box Packaging?

Q. Are printing and branding options available for Bra Boxes?

Q. What insert options are offered inside Bra Boxes?

Q. Are these boxes suitable for gifting and retail display?

Q. Do you offer eco-friendly options for Bra Box Packaging?

Q. What is the minimum order quantity (MOQ) for Bra Boxes?

Q. Can I order samples before placing a bulk order?

Q. How long is the production turnaround for custom Bra Box Packaging?

Q. Can I order mixed colours or styles in a single batch?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.