| Type | Specification |

|---|---|

| Product Name | Bubble Candle Packaging |

| Box Style | Rigid box, tuck-end box, or custom die-cut structure |

| Primary Material | Rigid chipboard, kraft paperboard, or SBS cardboard |

| Material Thickness | 350–1400 GSM depending on protection level |

| Structural Design | Engineered to support irregular bubble candle geometry |

| Internal Support | Custom-fit inserts, cavities, or molded paper trays |

| Surface Finish | Matte, gloss, soft-touch lamination, or natural kraft |

| Colour Options | CMYK, PMS colour matching, or raw kraft tone |

| Printing Technology | Offset lithography or high-resolution digital printing |

| Ink Specification | Low-VOC, non-toxic, wax-safe inks |

| Logo Application | Custom printed, embossed, debossed, or foil-stamped logo |

| Brand Enhancements | Spot UV, metallic foiling, texture coating |

| Size Options | Fully custom dimensions based on bubble candle size |

| Candle Fit Tolerance | Precision die-cut with minimal movement allowance |

| Closure Type | Magnetic flap, tuck-lock, or sleeve enclosure |

| Edge Construction | Clean die-cut edges with reinforced corners |

| Load Capacity | Optimised for decorative wax candles |

| Protection Level | Shock-absorbing structure for fragile candle forms |

| Eco-Friendly Options | Recyclable, biodegradable, plastic-free configurations |

| Customisation Scope | Logo, colours, box style, inserts, finishes |

| Quantity Options | Low-volume and bulk manufacturing |

| Manufacturing Process | Die-cutting, scoring, rigid box wrapping |

| Primary Use | Luxury candle retail, gifting, eCommerce shipping |

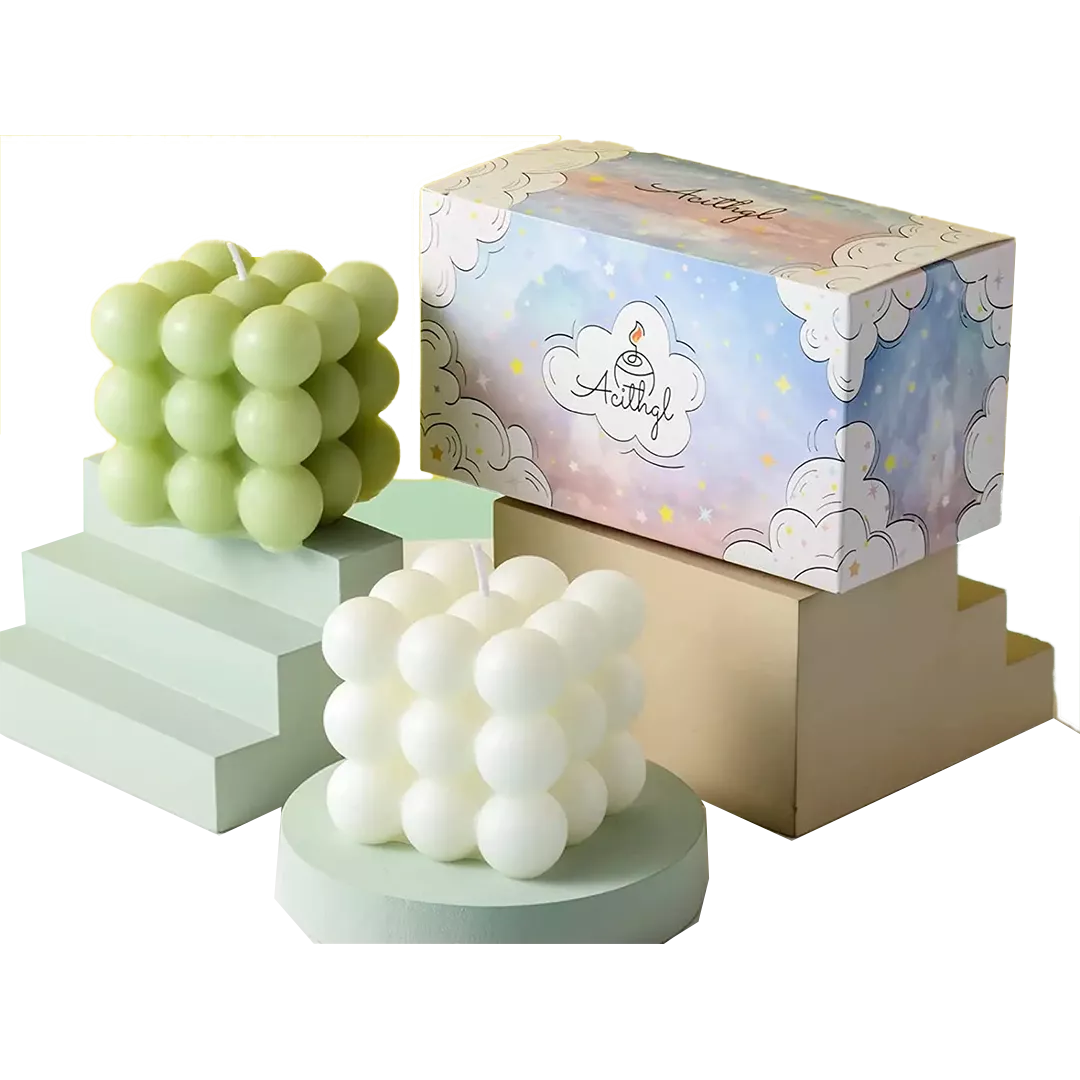

Bubble Candle Packaging

The Product Boxes UK offer superior bubble candle packaging that looks stylish to use to package your candles. We are famous for bespoke packaging solutions for different shapes of candles that make them look great and safe during storage and transportation. Our bubble candle boxes come in a variety of customisable sizes to suit the various candle designs, small boutique candles to large decorative objects.

The packaging has been designed using durable materials that do not get damaged and yet have a very classy, high-end appearance. Besides standard size, we also offer custom printing services through which you can include a logo, a brand name, or even promotional messages onto your packaging. Personalise your candle packaging with embossing, foil stamping, UV coating and make them to match your brand. No matter if you’re a candle maker, retailer or wholesaler, we provide wholesale pricing to buy candle packaging of the best quality. Call us today and place your order.

Starting From: £1 Per Box

Available in Stock

Q: What packaging challenges are specific to bubble candles?

Q: How does bubble candle packaging prevent shape deformation?

Q: Which internal packaging features work best for bubble candles?

Q: What materials are most suitable for bubble candle packaging?

Q: How does packaging protect the surface finish of bubble candles?

Q: Is bubble candle packaging designed differently for retail and shipping?

Q: How does packaging help maintain scent quality in bubble candles?

Q: Are window boxes suitable for bubble candle packaging?

Q: What packaging features support premium positioning of bubble candles?

Q: What quality checks are critical for bubble candle packaging?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.