| Type | Specification |

|---|---|

| Material | Food-Grade Kraft, Corrugated Cardboard, SBS Paperboard |

| Printing Options | CMYK, PMS, Digital, Offset, UV Printing |

| Finishing | Matte, Gloss, Soft-Touch, Spot UV, Aqueous Coating |

| Thickness | 14pt, 16pt, 18pt, 24pt (Custom Thickness Available) |

| Customization | Size, Shape, Color, Logo, Window Cutout, Embossing, Debossing |

| Closure Style | Auto-Lock, Tuck-End, Open Sleeve, Wrap-Around |

| Size Options | Standard (4×4 inches, 5×5 inches) & Custom Sizes |

| Printing Side | Single-Sided, Double-Sided |

| Eco-Friendliness | 100% Biodegradable, Recyclable, Compostable |

| Quantity | Minimum Order: 100 | Bulk Orders Available |

| Usage | Burgers, Sandwiches, Wraps, Fast Food Packaging |

| Production Time | 7-12 Business Days (Rush Orders Available) |

| Shipping | Flat-Packed or Pre-Assembled |

Burger Sleeve Packaging

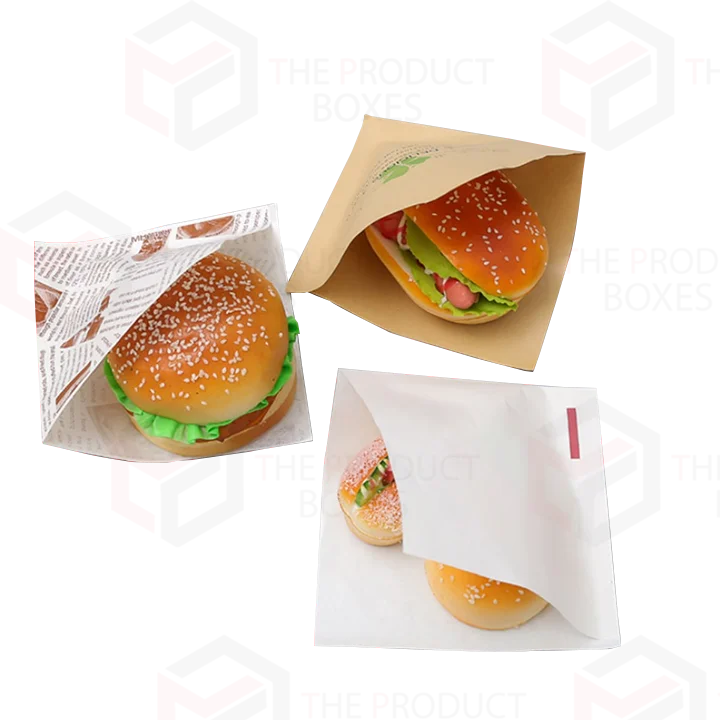

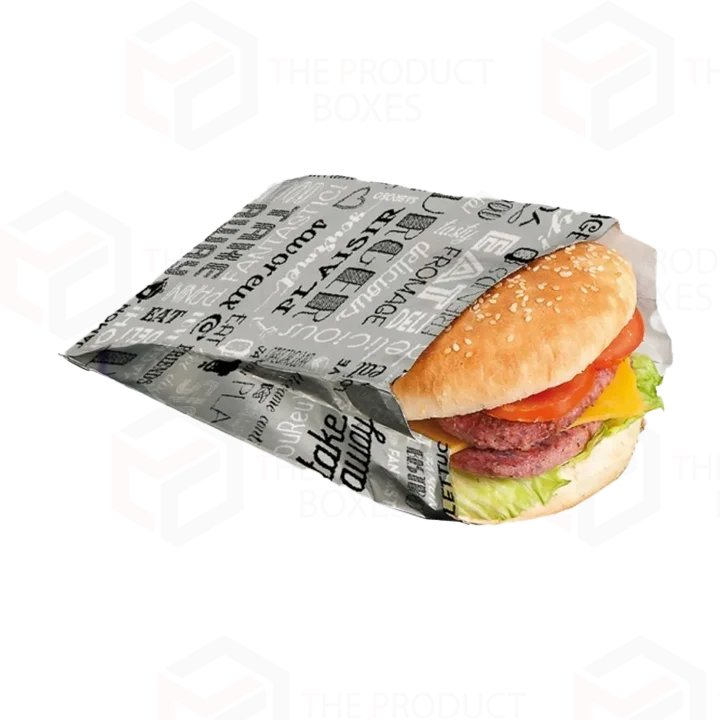

Burger sleeve packaging elevates your food serving style with a secure and eco-friendly way to serve burgers. These sleeves ensure mess-free consumption while keeping the burger fresh and helps in easy gripping. Crafted from high quality food grade cardboard or kraft, these sleeves are perfect for eateries like fast food chains, restaurants and takeaway outlets. The Product Boxes offer custom food packaging sleeves that allows you to personalise it with vibrant colours, logo print, matte/gloss finish and eco-friendly coating.

We also offer the choice of open or enclosed or open ended sleeves and any size to best fit your branding needs. For those businesses with bulk order requirements, our wholesale cardboard sleeve packaging will not only be at budget- friendly pricing but will also allow you a premium quality solution for food service. Enhance customer experience and your brand with custom sleeves that serve the purpose. Get in touch with The Product Boxes UK today to custom design high quality burger sleeves for your business.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Burger Sleeve Packaging?

Q. Can I customize the size and design of Burger Sleeve Packaging?

Q. Are Burger Sleeves safe for food contact?

Q. What printing options are available for Burger Sleeve Packaging?

Q. Are Burger Sleeve Packages eco-friendly?

Q. Can I add my company logo and branding to Burger Sleeves?

Q. What closure styles are available for Burger Sleeve Packaging?

Q. What is the minimum order quantity for custom Burger Sleeves?

Q. Do you offer grease-resistant coatings for Burger Sleeve Packaging?

Q. What industries commonly use Burger Sleeve Packaging?

Q. What is the production time for Burger Sleeve Packaging?

Q. Do you offer flat-packed or pre-assembled shipping for Burger Sleeves?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.