| Type | Specification |

|---|---|

| Material | High-quality food-grade cardboard, Kraft, corrugated |

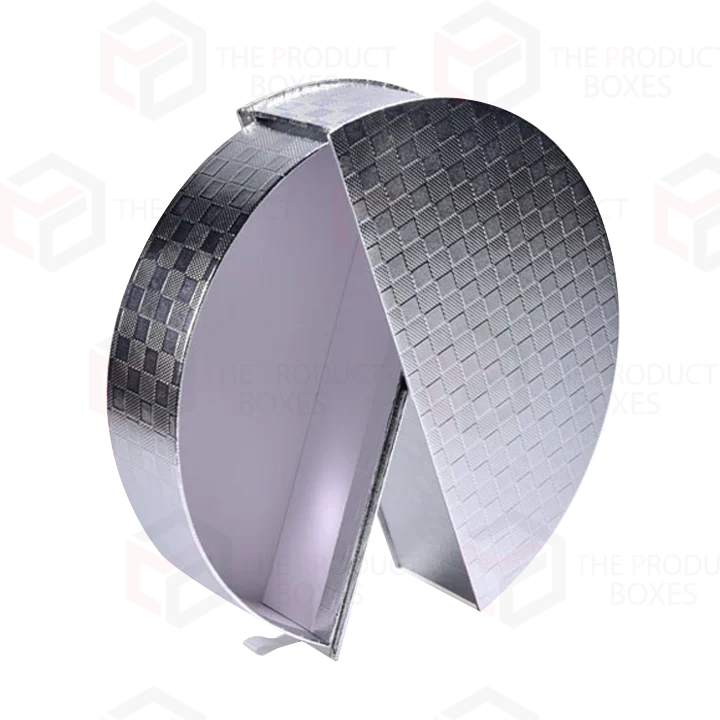

| Printing | Custom full-colour CMYK, PMS, embossing, foil stamping |

| Finishing | Matte, gloss, UV coating, spot UV, soft-touch lamination |

| Logo | Custom printed, embossed, debossed, hot foil stamping |

| Sizes | Available in all standard and custom sizes |

| Quantity | MOQ starts from 100 pieces, bulk orders available |

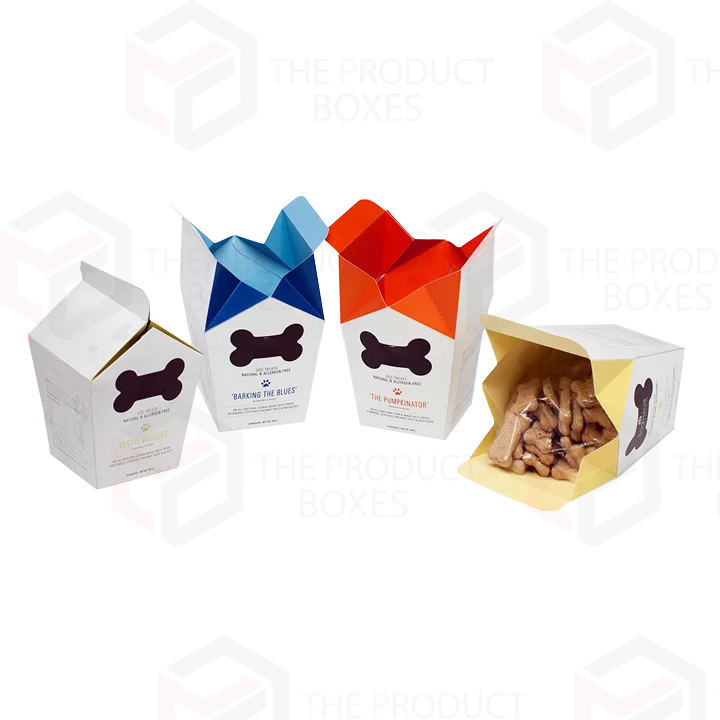

| Box Styles | Die-cut window, tuck-top, sleeve, handle boxes |

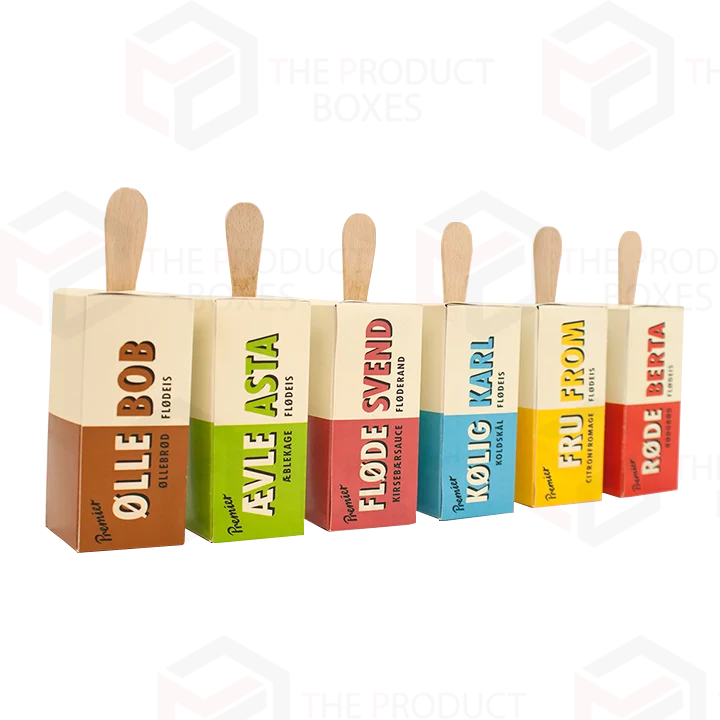

| Usage | Ice cream tubs, frozen desserts, gelato, sorbet |

| Customization | Shape, size, print, coatings, inserts, handle options |

| Eco-Friendly | Recyclable, biodegradable, compostable materials available |

Cardboard Ice Cream Boxes

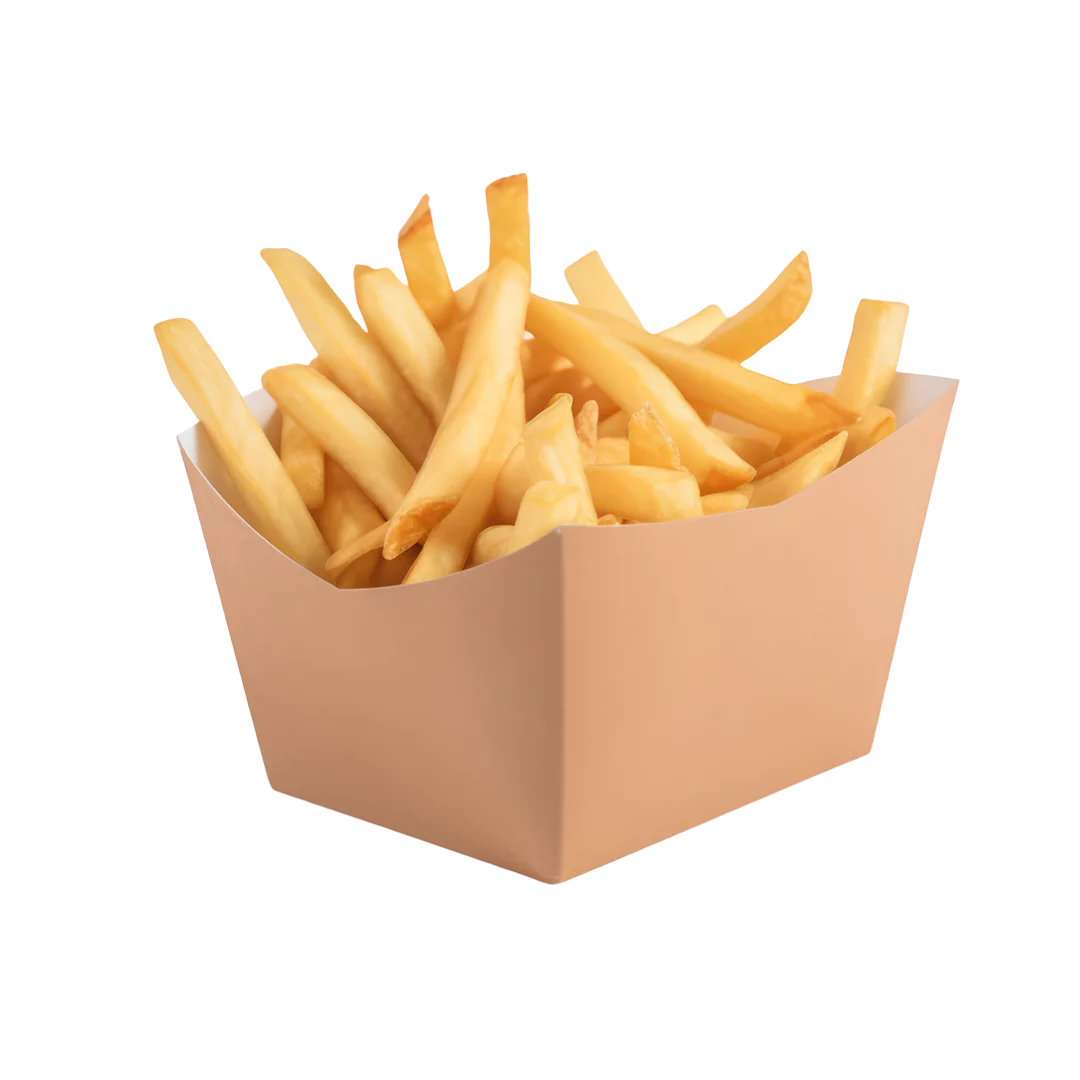

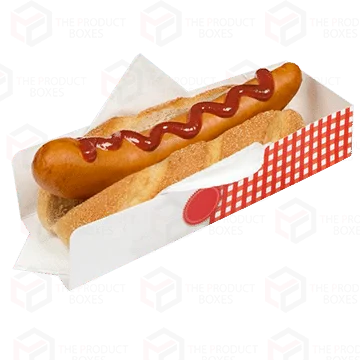

Keep your frozen-treats well-protected inside cardboard ice cream boxes. These boxes are popular through their durability and insulation abilities while offering attractive branding options with free design. Ice creams, gelato and frozen desserts stay fresh within these durable storage solutions throughout their transit and storage period. Food-grade cardboard composed of moisture-resistant materials allows these ice cream packaging boxes to deliver leak-proof as well as eco-friendly packaging solutions to dessert shops.

At The Product Boxes UK, we allow the customers to get custom food packaging boxes with logo for individual branding requirements. Companies can select from numerous box sizes dimensions together with matte or glossy finishes and can add vivid colours to achieve luxury aesthetics. We also add customised inserts together with secure locking features for convenient usage. Our company provides wholesale cardboard ice cream boxes to customers who need bulk packaging solutions at affordable prices. Contact The Product Boxes now to create ice cream boxes that will improve your brand image.

Starting From: £0.70 Per Box

Available in Stock

Q. What materials are used to make Cardboard Ice Cream Boxes?

Q. Are these ice cream boxes safe for frozen desserts?

Q. Can I get custom printing on my ice cream boxes?

Q. What sizes are available for these boxes?

Q. Are the ice cream boxes eco-friendly?

Q. Do these boxes come with lids?

Q. What is the minimum order quantity (MOQ) for custom ice cream boxes?

Q. How long does it take to manufacture and deliver custom ice cream boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.