| Type | Specification |

|---|---|

| Material | Corrugated cardboard, kraft paperboard, SBS (Solid Bleached Sulphate), recyclable and food-grade materials |

| Coating Options | Gloss AQ, Matte AQ, UV coating, water-based food-safe lamination |

| Printing | CMYK, Pantone, offset, digital, flexo printing available with food-safe inks |

| Custom Logo | Offset printed, embossed, debossed, foil stamped (gold/silver/holographic) |

| Sizes | Custom dimensions available (width × depth × height), die-cut or standard |

| Colours | Full-colour (4/4), PMS match, kraft brown, white, or custom shades |

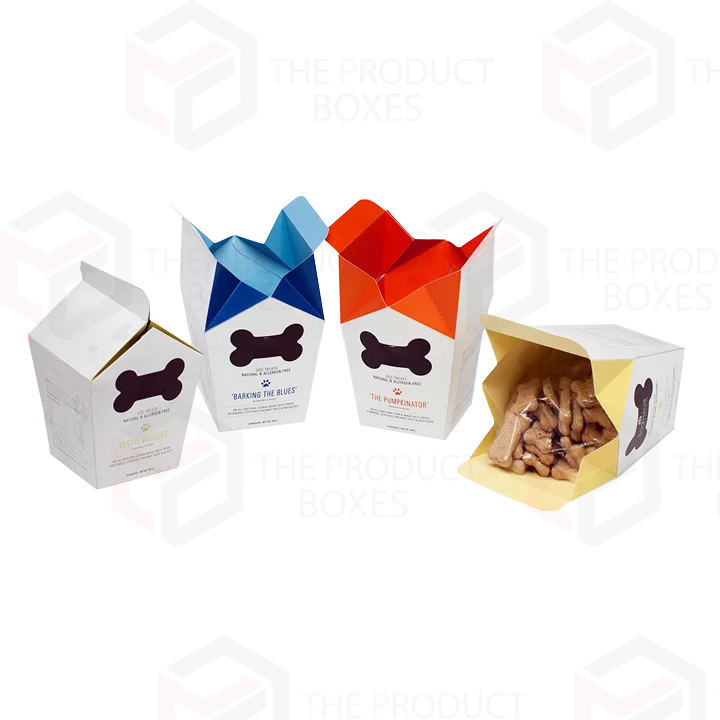

| Box Styles | Auto-lock bottom, tuck-end, window cut-out, sleeve, tray & lid, gable |

| Window Options | PET or PVC food-safe film windows (clear, frosted, shaped) |

| Closure Mechanism | Tuck flap, friction lock, magnetic flap, glued ends |

| Quantity | MOQ starts from 500 units – bulk runs up to 100,000+ |

| Certifications | FDA compliant, FSC-certified, ISO food safety compliant |

| Insert Options | Food-grade paper liners, corrugated dividers, greaseproof tray holders |

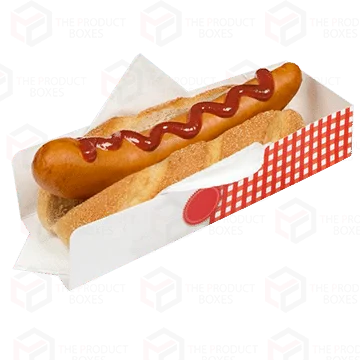

| Use Cases | Bakery, snacks, frozen food, dry goods, takeaways, meal prep kits |

| Recyclability | 100% recyclable, biodegradable, compostable options available |

| Production Time | 7–12 business days post-artwork approval (rush options available) |

Commercial Food Packaging Boxes

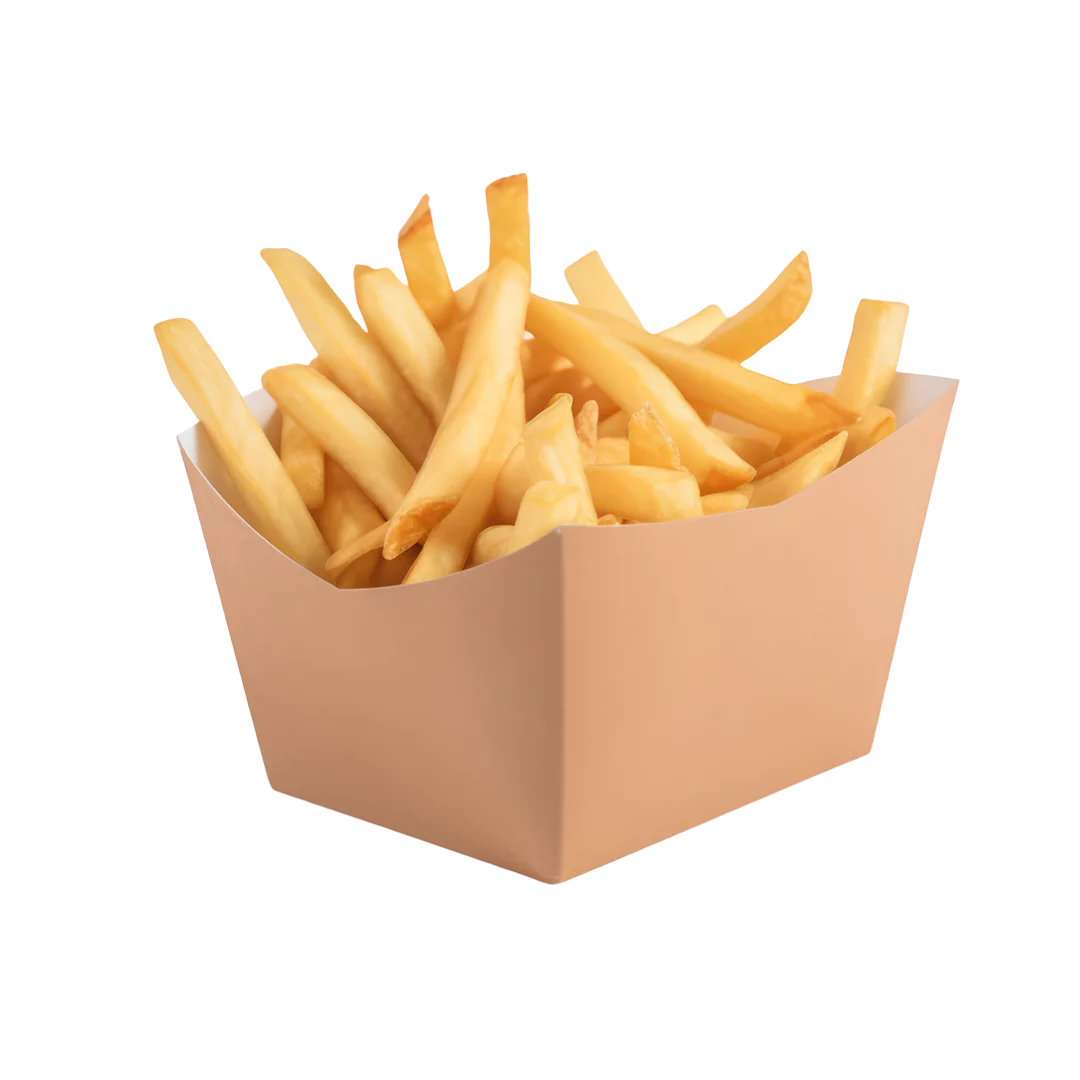

Everyone knows very well that the food that remains fresh inside the packaging does not lose its texture. And when it comes to packing the food, there are a number of things that need to be focused on. First of all, the commercial food packaging boxes quality needs to be leakage-proof, protective, and contamination-free.

The second thing is customisation, which includes your branding details on the food boxes. So, at The Product Boxes UK, our professional team creates high-quality commercial and custom food packaging boxes that preserve product freshness. However, with the custom printing options, our team makes your custom food packaging boxes with logo to reflect your brand’s unique identity. You can also try our rigid food packaging to make your takeaways safe and protective.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Commercial Food Packaging Boxes?

Q. Can I customise the design and printing of food packaging boxes?

Q. Are these boxes safe for direct contact with food?

Q. What types of food are these packaging boxes suitable for?

Q. Are these boxes microwave and freezer safe?

Q. What is the minimum order quantity (MOQ) for custom commercial food boxes?

Q. What types of coatings and finishes can be applied to these boxes?

Q. Do you offer window cutouts or clear display panels?

Q. Can I order food packaging boxes in various sizes and styles?

Q. How fast can I receive my customised commercial food boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.