| Type | Specification |

|---|---|

| Product Name | Custom Liquid Foundation Boxes |

| Material | SBS C1S/C2S paperboard, Kraft board, corrugated cardboard, rigid chipboard |

| Box Style | Auto-lock bottom, tuck-end, straight tuck, reverse tuck, two-piece, sleeve |

| Color Options | Full-color CMYK, PMS spot colors, solid base tones, metallics |

| Logo Application | Printed, foil-stamped, embossed, debossed, or spot UV |

| Finish & Coating | Gloss, matte, soft-touch, aqueous, UV coating, anti-scratch lamination |

| Box Dimensions | Custom-fit for 15ml to 50ml foundation bottles; adjustable on request |

| Thickness | 14pt, 16pt, 18pt, 20pt, 24pt (paperboard); 32pt+ (rigid) |

| Printing Method | Offset, digital, screen printing, UV spot, litho-lamination |

| Insert Options | Die-cut paperboard, molded pulp, foam, blister insert on request |

| Eco Options | Recycled kraft, biodegradable board, soy-based inks available |

| Use Case | Retail shelf display, e-commerce packaging, subscription kits, gift sets |

| Quantity Range | Minimum 100 units, scalable to bulk commercial orders |

| Window Options | Clear PVC window, die-cut window, no window (optional) |

| Assembly | Flat-packed or pre-assembled (based on structure) |

| Turnaround Time | 7–10 business days after proof approval (rush options available) |

| Customization | Full custom specs including material, size, print, inserts, and branding |

Custom Liquid Foundation Boxes

Custom liquid foundation boxes are fundamental in boosting the attractiveness, safety, and marketing of your cosmetic products. The Product Boxes UK offer custom design and production of packaging boxes that represent your brand and ensure that sensitive liquid foundation bottles are not leaked, broken, or damaged. These skincare product boxes are made with premium material such as cardboard or stiff stock and they can be completely customised with regards to size, shape, finish and style. Desire a minimalist chic look or large, colourful prints? Our skilled team assists in making your vision a reality through high-resolution printing, custom die-cut windows, embossing, foil stamping, and UV coating.

These packaging improvements also assist in offering such vital information as ingredients, shade information and usage directions in an appealing way. Our custom liquid foundation boxes are more than boxes, they are a representation of your product personality. Our boxes are sophisticated and durable enough to be used both on retail shelves and in e-commerce shipping. Contact The Product Boxes when you want eco-friendly, cost-efficient, and gorgeous cosmetic packaging uk to stand out in the crowd.

Starting From: £0.50 Per Box

Available in Stock

Q. What is the best packaging box for liquid foundation bottles?

Q. How do custom foundation boxes help with brand recognition?

Q. Can liquid foundation boxes be designed for glass bottles?

Q. Why use custom packaging for foundation products?

Q. What type of insert is best for foundation bottle packaging?

Q. Are foundation boxes recyclable and eco-friendly?

Q. How thick should foundation packaging boxes be for safety?

Q. Can I print foundation shade or ingredients on the box?

Q. Where can I order custom boxes for liquid foundation in the UK?

Q. How do I measure my bottle for a custom box design?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

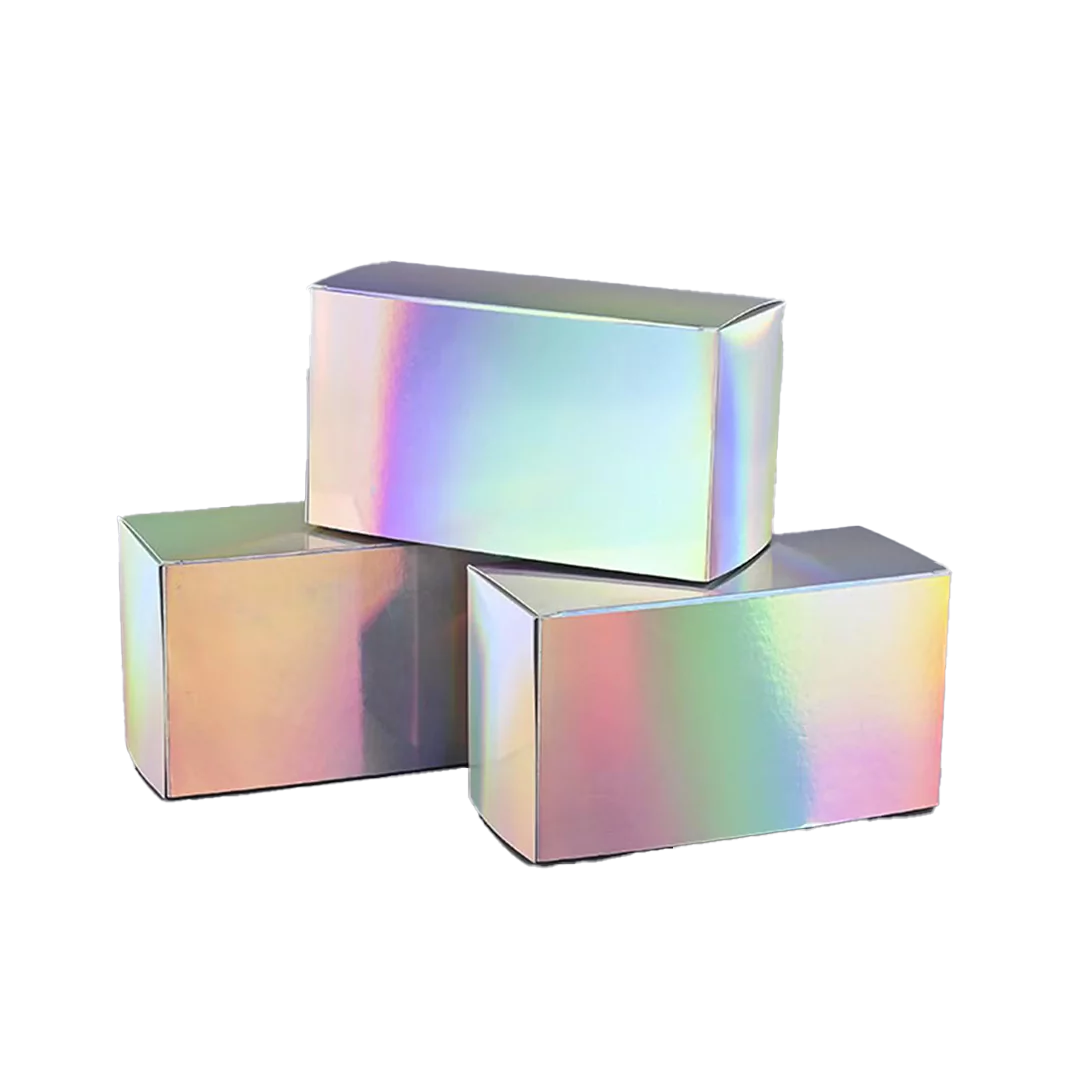

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.