| Type | Specification |

|---|---|

| Material | Rigid cardboard, corrugated paperboard, kraft paper, SBS (Solid Bleached Sulfate) |

| Size | Custom dimensions available; typical range 6″ x 4″ x 2″ to 24″ x 18″ x 12″ |

| Full-colour CMYK & PMS spot colours, digital & offset printing, high resolution | |

| Logo | Custom logo printing via screen print, foil stamping, embossing, debossing, UV coating |

| Colour Options | Matte, gloss, soft-touch lamination; custom Pantone matching |

| Closure Type | Tuck flaps, auto-lock, magnetic, adhesive strips |

| Quantity | Minimum 100 units; bulk production up to unlimited volumes |

| Finish | Spot UV, aqueous coating, textured or metallic finishes, varnish |

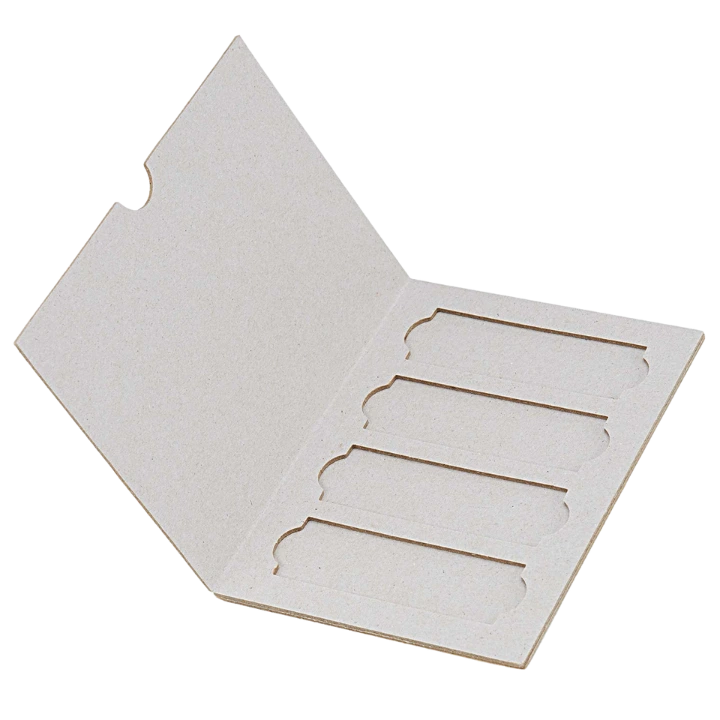

| Inserts | Custom foam, cardboard dividers, molded pulp, velvet or silk lining |

| Eco-Friendly | FSC certified, recyclable, biodegradable, soy-based inks available |

| Assembly | Flat-packed or pre-assembled, automated die-cut, creasing, and folding |

| Durability | Water-resistant coatings, tear-proof lamination, crush-resistant structure |

| Customization | Custom shapes, sizes, finishes, and branding options tailored per project |

Custom Mailer Boxes With Logo

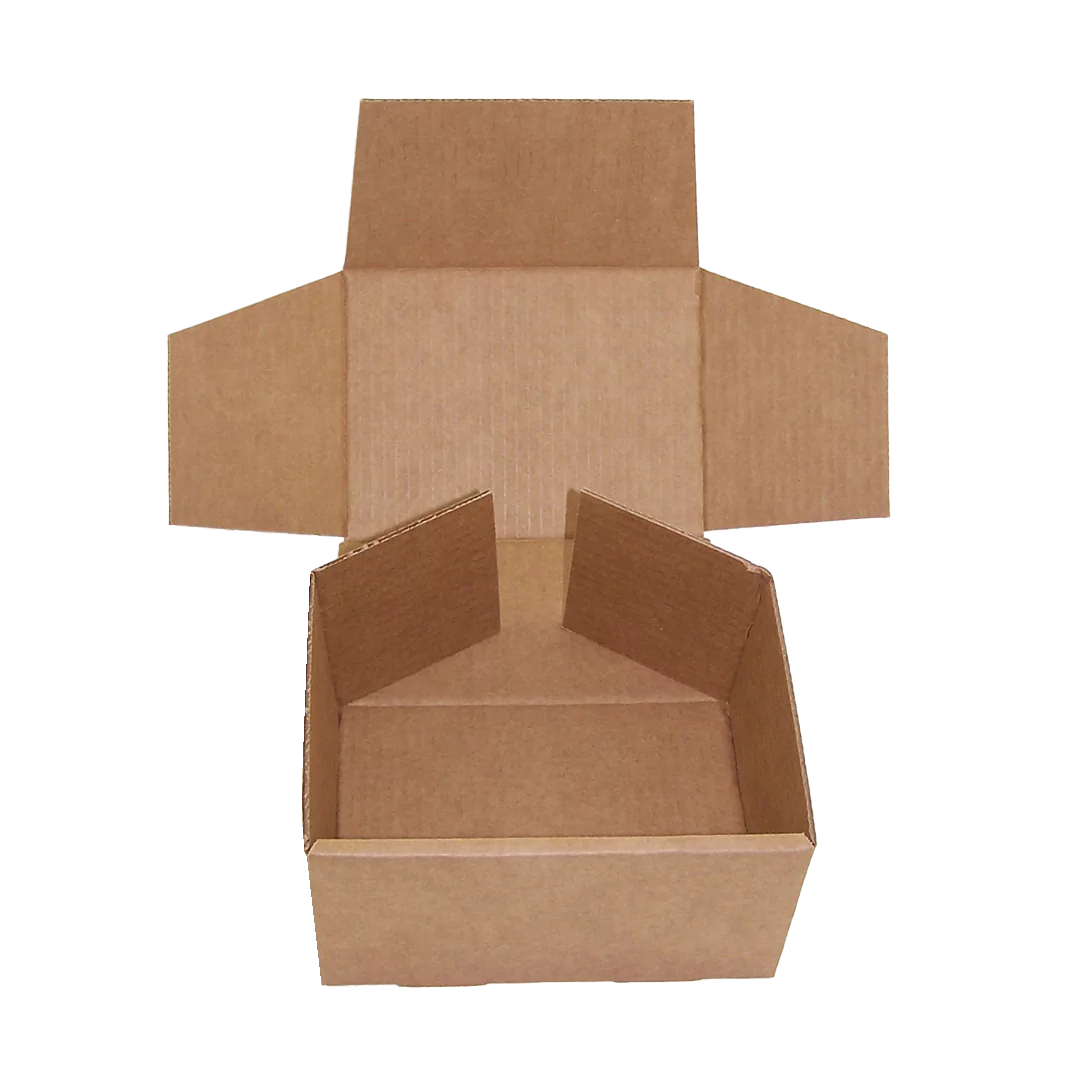

Do you want to make a strong opening impression with your logo? If yes, contact The Product Boxes UK. Our custom mailer boxes with logo are well-suited for shipping goods in eCommerce, receiving subscription boxes, retail projects, and delivering gifts or samples, combining security with a polished look. Crafted with durable corrugated cardboard, our mailer boxes are designed for a special unboxing feeling. Printing your logo, brand colours, and design elements on the box gives your packaging a branding role.

Pick between tab-lock, roll-end, self-seal, or tuck-in flap styles and determine the specific dimensions that work best for your products. If you choose to have your text or images in just a few colours or in full colour, we provide quality digital, offset, and screen printing as well as matte/gloss lamination, spot UV, embossing, or foil stamping. With us, you can easily create your product, receive fast support, and get bulk or wholesale discounts. Get in touch with us today to order custom product boxes with logo and make every shipment special for your brand.

Starting From: £1 Per Box

Available in Stock

Q. What materials are used to make Custom Mailer Boxes With Logo?

Q. Can I customise the size and design of Custom Mailer Boxes?

Q. What printing options are available for these mailer boxes?

Q. Can I add my logo on Custom Mailer Boxes?

Q. What finishes can be applied to Custom Mailer Boxes?

Q. Are these boxes suitable for fragile products?

Q. Are eco-friendly materials available for these mailer boxes?

Q. What closure options do Custom Mailer Boxes have?

Q. Can these boxes be shipped flat?

Q. What is the minimum order quantity for Custom Mailer Boxes With Logo?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.