| Type | Specification |

|---|---|

| Box Style | Auto-lock bottom, tuck top, hinged lid, window patching (optional) |

| Material | Food-grade Kraft, SBS C1S/C2S, corrugated board (eco & recyclable options) |

| Coating | Grease-resistant, aqueous, matte, gloss, soft-touch, or UV spot finish |

| Logo Options | Offset printed, hot foil stamped, embossed, debossed, screen printed |

| Colour Support | CMYK, Pantone (PMS) matching system, metallic & neon inks available |

| Box Sizes | Custom-fit for pie slices, mini pies, and whole pies (e.g., 6″, 8″, 10″, 12″) |

| Window Feature | PVC, PET, or biodegradable PLA clear window with die-cut options |

| Printing Method | Digital, flexographic, and offset printing with photo-quality output |

| Finishing | Gloss/matte lamination, soft-touch coating, spot UV, edge gilding |

| Quantities | Low MOQs for small businesses to bulk production for large orders |

| Certifications | FDA food-safe compliant, FSC certified paper available |

| Custom Inserts | Optional die-cut inserts for secure holding and presentation |

| Assembly | Flat-packed for shipping; easy to assemble with pre-scored lines |

| Usage | Ideal for bakeries, cafés, delis, and dessert takeout packaging |

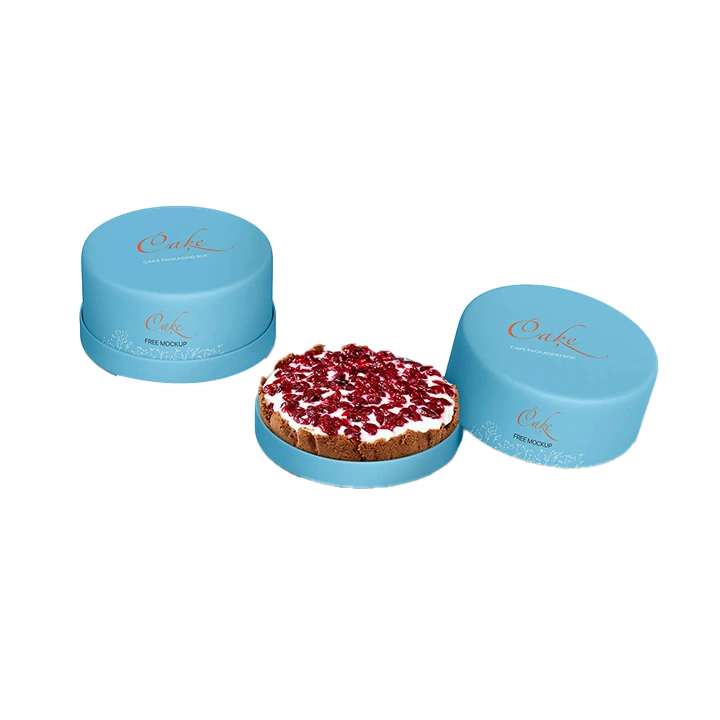

Custom Pie Boxes With Logo

If you are looking for an impressive kickstart that will make your pies viral among the masses with their brand recognition, then custom pie boxes with logos are the best solution. We offer exclusively designed and custom printed pie boxes that are printed with the latest technology. So, the final look of these boxes is very attractive. It means if you are running a small business, then these branded pie boxes will be your best packaging option.

Moreover, our special team uses your brand-relevant colour theme for food packaging boxes with logos, making your pie look more relevant to the brand. So, place your order with “The Product Boxes” and enjoy free delivery across the UK.

Starting From: £0.75 Per Box

Available in Stock

Q. What materials are used to make Custom Pie Boxes with Logo?

Q. Can I add my logo to the pie boxes?

Q. Are these boxes safe for food packaging?

Q. Do you offer custom shapes and sizes?

Q. Can these pie boxes include a display window?

Q. What printing options are available for custom pie boxes?

Q. Are your pie boxes eco-friendly?

Q. Can I get a sample before placing a bulk order?

Q. What is the production turnaround time?

Q. How are the pie boxes shipped?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.