| Type | Specification |

|---|---|

| Product Name | Custom Printed Food Tray Liners |

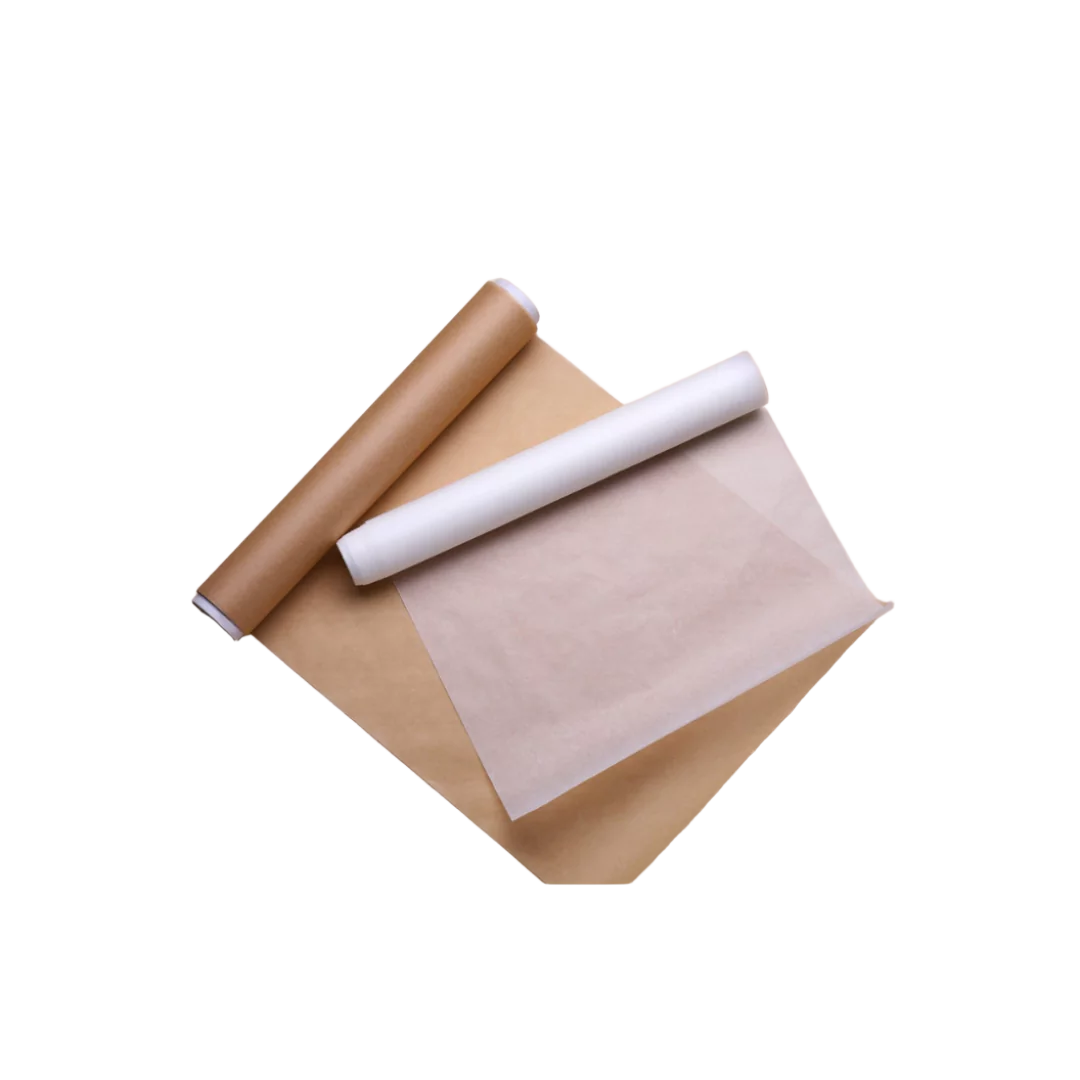

| Material Options | Greaseproof paper, Kraft paper, parchment sheet, wax-coated or uncoated stock |

| Paper Weight | 30 GSM to 60 GSM (lightweight to premium-grade) |

| Printing Process | Flexographic, digital, or offset printing with full CMYK or PMS colour support |

| Colour Options | Natural brown, bright white, dyed tones, or full-colour branding |

| Logo Customisation | Edge-to-edge, central placement, repeating pattern, or single logo print |

| Finish Type | Matte, gloss, soft-touch, or semi-wax coating for moisture resistance |

| Printing Resolution | Up to 1200 DPI for crisp text and logo detailing |

| Sheet Sizes | Standard 10×10″, 12×12″, 14×14″, or fully custom dimensions |

| Edge Treatment | Straight cut, zigzag edge, or perforated tear line |

| Ink Type | Food-safe, odourless, soy-based or water-based inks |

| Coating Options | Greaseproof, waxed, PLA barrier, or AQ coating |

| Moisture Resistance | Oil, sauce, and liquid-resistant layers for tray and basket lining |

| Customisation Options | Logo, artwork, pattern, size, colour, and fold style available |

| Eco Certification | FSC® certified, recyclable, compostable, and biodegradable |

| Application | Tray liners for fast food, deli, bakery, or restaurant serving |

| Packaging Form | Flat sheets or roll format for dispenser use |

| Quantity Range | MOQ 500 sheets up to 100,000+ bulk orders |

| Temperature Resistance | Safe from -10°C to +90°C for hot or cold food trays |

| Odour Barrier | Maintains aroma integrity and prevents grease transfer |

| Printing Alignment | Edge-aligned or centred print pattern accuracy |

| Surface Texture | Silky smooth or natural kraft texture finish |

| Design Options | Single-sided or double-sided printing with brand artwork |

| Production Method | Precision die-cut and sheet-trimmed for consistent layout |

| Lead Time | 7–12 working days for custom print runs |

| Shipping | Flat-packed, moisture-protected cartons for export handling |

| Custom Offer | On-demand personalised tray liners with brand design and eco options |

Custom Printed Food Tray Liners

Turn every meal into a marketing opportunity with custom printed food tray liners that do more than catch crumbs—they showcase your restaurant or catering brand directly where customers are looking. These liners transform ordinary serving trays into professional presentations that keep your business top of mind. We print on grease-resistant paper stock that handles everything from burgers and fries to pastries and sandwiches without soaking through. Your logo, menu highlights, or promotional messages print in vibrant colors that stay sharp even under hot food. Choose from standard rectangular sizes or custom die-cut shapes that fit your specific tray dimensions perfectly.

Food businesses love these liners because they’re practical and promotional. Customers see your branding throughout their entire meal, and many even take photos for social media—free advertising for you. Perfect for fast-casual restaurants, food halls, catering companies, cafeterias, and event venues looking to elevate their food presentation. The Product Boxes delivers food-safe printed liners that meet health standards while building your brand. Available in kraft, white, or colored paper stock. Minimum order 2500 liners with bulk discounts for regular reorders. Quick turnaround on repeat orders keeps your kitchen stocked without long waits.

Starting From: £0.20 Per Box

Available in Stock

Q. What material works best for custom printed food tray liners?

Q. How durable are printed food tray liners for hot and oily meals?

Q. Can I match my brand colours and logo accurately on tray liners?

Q. What sizes are most popular for food tray liners in cafes and restaurants?

Q. Are custom tray liners safe for direct food contact?

Q. Can I order custom printed food tray liners in small quantities?

Q. How can custom tray liners help with brand promotion?

Q. What eco-friendly options are available for food tray liners?

Q. Can tray liners be used for wrapping food as well?

Q. How can bulk ordering save on printing costs for food tray liners?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.