| Type | Specification |

|---|---|

| Material | Premium Kraft, Corrugated Cardboard, Rigid Paperboard, SBS Paperboard |

| Printing Options | CMYK, PMS, Digital, Offset, Screen Printing |

| Customization | Full-Color Printing, Custom Sizes, Die-Cut Shapes, Embossing, Debossing, Foil Stamping |

| Thickness | 250 GSM – 450 GSM (Customizable) |

| Coating & Finishes | Gloss, Matte, Soft-Touch, Spot UV, Anti-Scratch, Aqueous Coating |

| Sizes | Customizable to Fit Various Products (Food, Cosmetics, Retail, Apparel, Electronics) |

| Window Options | Clear PVC, Biodegradable PLA, Die-Cut Open Window |

| Logo & Branding | Custom Logo Printing, Hot Stamping, Raised Ink, Embossed Logos |

| Closure Type | Slide-On, Tuck-End, Self-Locking, Perforated Tear Strip |

| Quantity | Available in Bulk (Minimum 100 Pieces) |

| Eco-Friendly Options | 100% Recyclable, Biodegradable, FSC-Certified Materials |

| Usage | Ideal for Product Branding, Retail Packaging, Food & Beverage, Cosmetics, Promotional Items |

| Shipping & Storage | Flat-Packed or Pre-Assembled Options Available |

| Production Time | 7-12 Business Days (Express Production Available) |

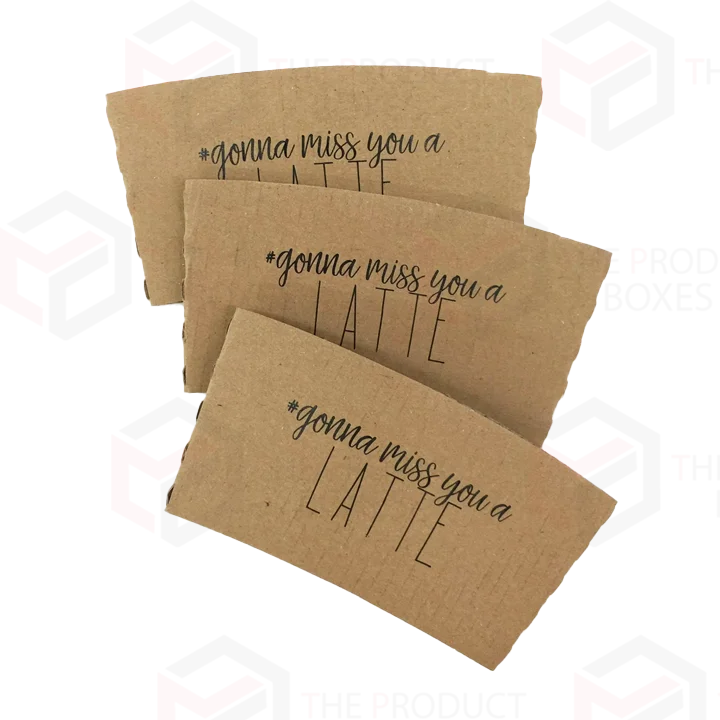

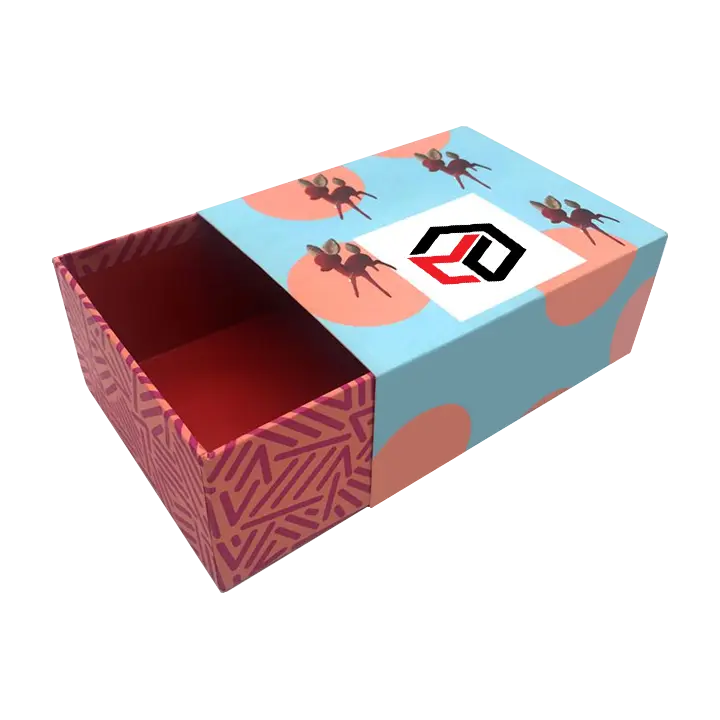

Custom Printed Packaging Sleeves

Custom printed packaging sleeves act as an affordable solution which enhances product display through their stylish wrapping capabilities. These adjustable sleeves transform into protective coverings that envelop various types of boxes, bottles as well as food containers and other products with branding and premium appearance capabilities. Through their ability to enhance food and cosmetic products and stores together with promotional merchandise they offer professional aesthetics. Our company, The Product Boxes UK creates custom packaging sleeves that fit requirements of each individual client brand.

You can select materials with colourful designs and embossing along with foil stamps and matte/gloss finishing options to make your design more noticeable. The Product Boxes deliver high-quality solutions for branded paper sleeves with logo to fulfill any requirements. The company delivers wholesale belly band sleeves which combine affordable pricing with high production quality for bulk ordering needs. Design your products to stand out by focusing on your brand while also making them look attractive. Contact The Product Boxes for creating top-quality packaging sleeves for memorable packaging experiences

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Custom Printed Packaging Sleeves?

Q. Can I customize the size and design of my packaging sleeves?

Q. What printing options are available for branding?

Q. Are these packaging sleeves eco-friendly?

Q. Can I add a logo and custom branding elements?

Q. Do you offer different finishes and coatings?

Q. What is the minimum order quantity for custom packaging sleeves?

Q. How long does production and delivery take?

Q. Can you create die-cut or window packaging sleeves?

Q. Do you offer flat-packed or pre-assembled packaging sleeves?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.