| Type | Specification |

|---|---|

| Material | Corrugated cardboard (E-flute, B-flute, or double-wall), Kraft liner, or White SBS board |

| Printing | CMYK or Pantone offset printing, flexographic printing, digital print options |

| Logo Application | Foil stamping, embossing, debossing, spot UV, screen printing |

| Color Options | Full-colour, natural kraft brown, white base, or custom Pantone shades |

| Box Styles | Regular Slotted Carton (RSC), Full Overlap, Die-Cut, Self-Locking, Mailer |

| Coating & Finishes | Gloss, matte, soft-touch, AQ coating, UV varnish, lamination |

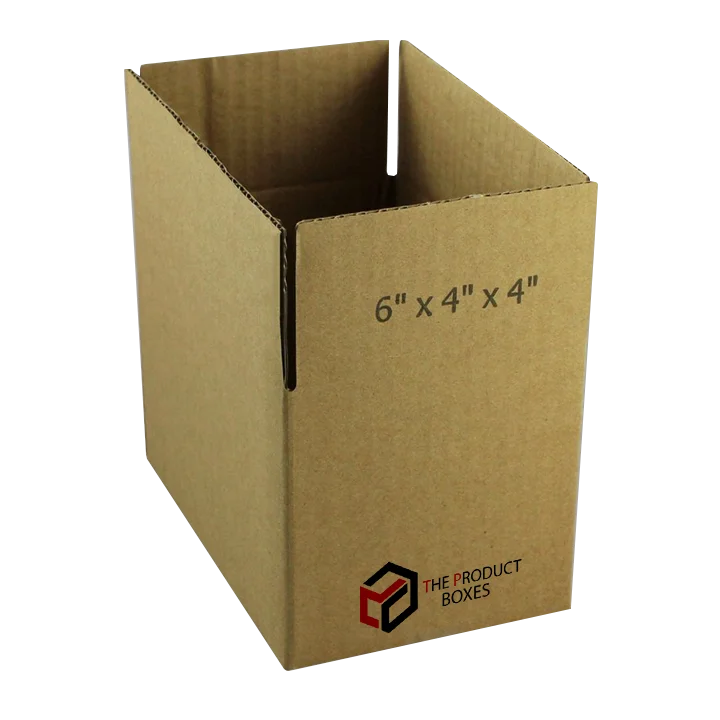

| Sizes | Fully custom – available in small parcel to large bulk freight sizes |

| Inserts | Corrugated dividers, molded pulp trays, foam inserts, or custom die-cut fittings |

| Load Capacity | Supports 5–50 kg depending on board strength and structural design |

| Closure Options | Standard flaps, tuck-in flaps, adhesive strip, self-locking, or tape-ready |

| MOQ | Low minimum order quantity available; scalable for bulk production |

| Quantity Range | From 100 units to 50,000+ units per run |

| Eco-Friendly Options | Recyclable, biodegradable board, soy-based inks, and water-based coatings |

| Turnaround Time | Standard 8–12 business days; rush production available |

| Applications | Ecommerce packaging, subscription boxes, retail shipping, industrial freight |

Custom Printed Shipping Boxes

Getting custom printed shipping boxes means to turn a delivery into a meaningful way to strengthen your brand. At The Product Boxes UK, we focus on giving you shipping boxes that safely carry your goods and represent your brand. If you use eCommerce, subscriptions or retail, our boxes help your parcel look special as soon as it is delivered. The corrugated materials are precisely selected and cut to fit your items’ dimensions, weight and shipment requirements. Place your logo, follow your brand colours, say what you need to and add graphics to strengthen your visibility and professional image with fine printing.

Each box we create matches your style. No matter if you want a simple drop shipping style or bright designs for a launch, we’ve all. Get the opportunity to pick eco-friendly items to prove you care about the environment. Our custom shipping boxes with logo wholesale are as strong and attractive as they are useful for promotion. If you purchase your custom printed product boxes from The Product Boxes, you’ll get free shipping and fast turnaround.

Starting From: £1 Per Box

Available in Stock

Q. Which board types are best suited for custom printed shipping boxes?

Q. Can I fully personalise the box with my brand visuals?

Q. Are these boxes suitable for fragile or heavy products?

Q. Do I have options for box size and structure?

Q. What types of finishes can enhance the box surface?

Q. Can the boxes be printed inside and outside?

Q. Are the printing methods eco-conscious?

Q. Do custom shipping boxes support retail and e-commerce use?

Q. Is there a minimum order quantity for printed shipping boxes?

Q. How long does it take to produce and deliver my custom boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.