| Type | Specification |

|---|---|

| Material Options | Corrugated cardboard, kraft board, SBS paperboard, chipboard, recycled fiberboard |

| Printing Methods | CMYK, PMS, digital printing, offset printing, screen printing, UV spot printing |

| Finishes | Gloss, matte, soft-touch lamination, anti-scratch coating, aqueous coating |

| Custom Shapes | Die-cut to any shape: circular, triangular, hexagon, product silhouette, abstract geometries |

| Logo Application | Foil stamping (gold, silver, holographic), embossing, debossing, raised UV |

| Box Styles | Two-piece, hinged lid, tuck top, mailer, auto-lock bottom, magnetic closure |

| Colour Options | Full-color CMYK, spot Pantone colors, custom gradients, white ink on kraft |

| Size Range | Fully customizable; available from small gift-sized (3″x3″) to large retail packaging (24″x18″) |

| Minimum Order Quantity | Starts from 100 units; MOQ may vary depending on structure and print complexity |

| Quantity Options | Available in low-run digital batches or large offset runs up to 100,000+ |

| Eco-Friendly Options | Recycled cardboard, biodegradable inks, water-based coatings, compostable lamination |

| Window Features | Die-cut windows with PET, PVC, or biodegradable PLA film; clear or frosted view panels |

| Structural Enhancements | Reinforced walls, inserts, partitions, magnetic closures, handle cutouts |

| Use Case | Retail, gift packaging, product launches, promotional kits, subscription boxes |

| Delivery Format | Shipped flat-packed for assembly or pre-assembled upon request |

| Lead Time | Standard production time: 7–12 business days after design approval |

Custom Shaped Cardboard Boxes

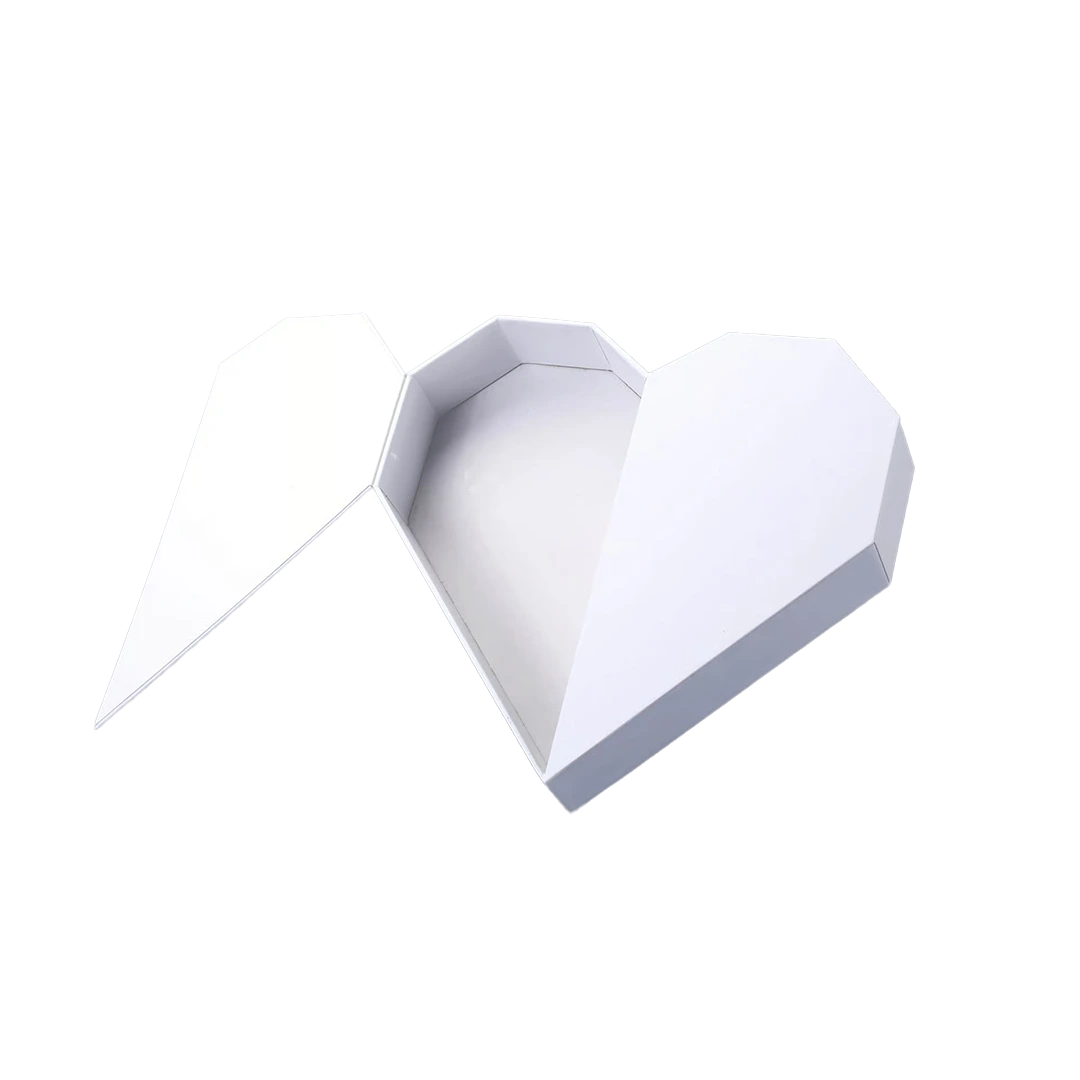

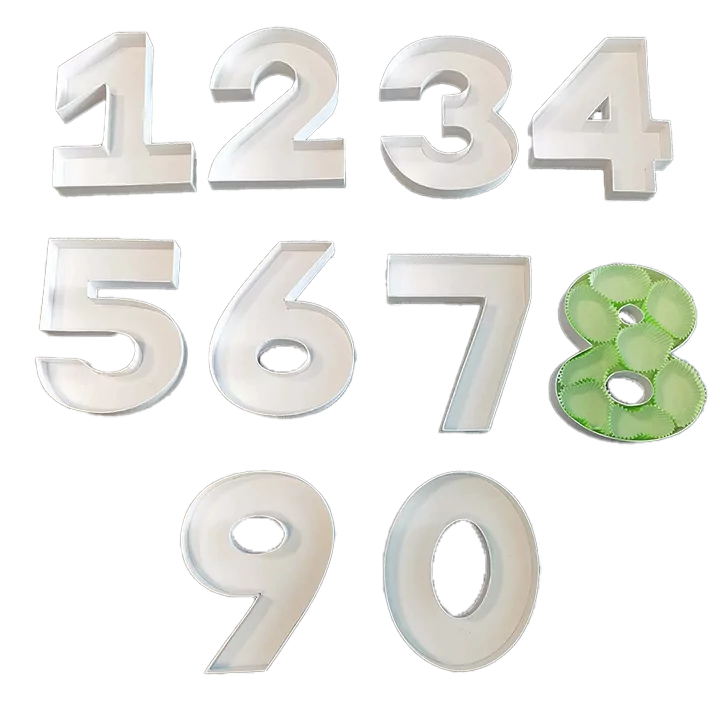

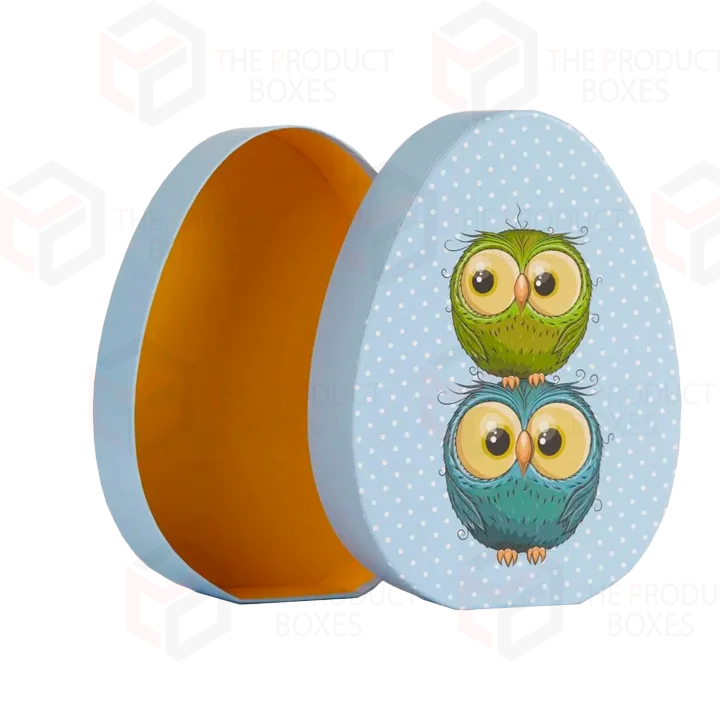

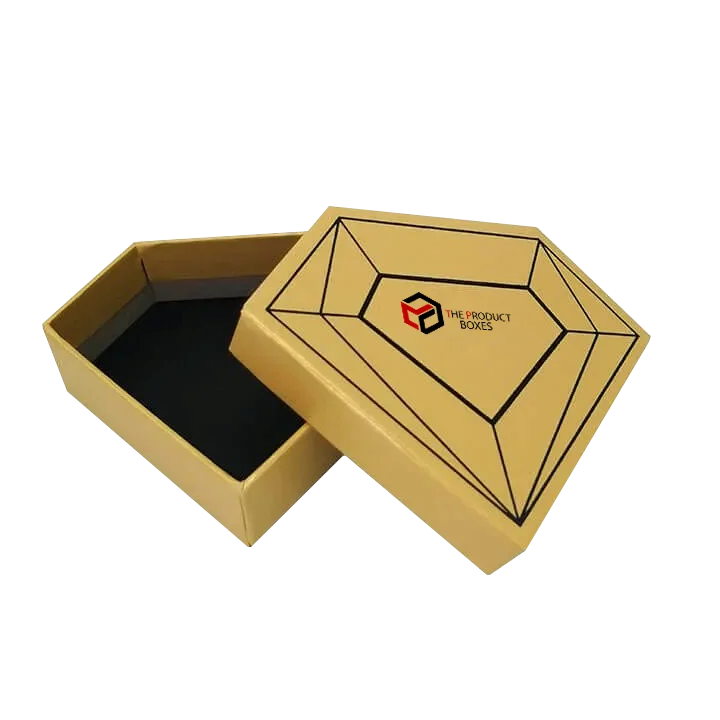

Using custom shaped cardboard boxes means your products stay attractive, well-protected and people remember your brand. You can choose from star, heart and hexagon-shaped boxes or design totally new shapes to fit your product’s shape. They help your item be more visible to customers, look attractive and stay in their memories. The Product Boxes UK is known for making distinctive custom cardboard boxes that are, at the same time, both attractive and strong. Made from hard corrugated or cardboard, our boxes keep items safe during the shipping and handling process.

Your custom options include die-cuts, created inserts, custom embossing, foiling and full-colour printing to suit your brand’s look. Cosmetics, gift items, confectionery, tech accessories and promotional goods all use these boxes to communicate the brand’s idea. No matter what you are launching, our different shape cardboard boxes make sure your brand stays in your customers’ minds. Contact us to ensure that your packaging looks exactly as you want it.

Starting From: £0.94 Per Box

Available in Stock

Q. What materials are used to make Custom Shaped Cardboard Boxes?

Q. Can I get any shape or die-cut design for my cardboard boxes?

Q. Are these boxes strong enough to protect fragile items?

Q. Can I print my brand logo and custom artwork on the boxes?

Q. Do you offer eco-friendly or recyclable versions of these boxes?

Q. What finishing options are available for these boxes?

Q. Can these boxes include special features like windows or magnetic closures?

Q. What is the minimum order quantity for custom shaped boxes?

Q. Do the boxes ship flat or pre-assembled?

Q. How long does it take to produce and deliver custom shaped cardboard boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.