| Type | Specification |

|---|---|

| Product Name | Fruit Shaped Juice Boxes |

| Material | Food-grade SBS paperboard, Kraft paper, Aluminum lining, PET film lamination (optional) |

| Printing Type | CMYK, PMS, UV Spot, Flexo, Digital, Foil stamping |

| Shape Options | Apple, Orange, Mango, Strawberry, Pineapple, Custom Fruit Shapes |

| Coating | Gloss/Matte Lamination, Aqueous Coating, Anti-scratch, Oil-based varnish |

| Capacity | 150ml, 200ml, 250ml, 300ml, Custom Volume on Request |

| Closure Style | Heat-seal top, Tamper-proof cap, Straw slot, Twist-off spout |

| Customization | Shape, Volume, Material Thickness, Straw Placement, Inner Coating Type |

| Surface Finish | Soft-touch, Glossy, Matte, Embossed texture for fruit skin effect |

| Logo Printing | Custom Logo, Full-wrap Branding, White-label Option |

| Color Options | Fruit-Match PMS, CMYK Full Color, Transparent or Solid Tint |

| Eco-Friendly Option | Recyclable, Compostable Kraft, Soy-based Inks, PLA Lamination |

| Inner Lining | Polyethylene, Aluminum Foil, PET barrier film (moisture & light protection) |

| Use Case | Juice Packaging, Smoothies, Health Drinks, Kids Beverages, Organic Juices |

| Minimum Order Quantity | 500 Units (Custom MOQ on request) |

| Packaging Style | Flat-packed for storage or pre-formed for ready-to-fill use |

| Compliance | FDA Approved, BPA-Free, ISO 22000, FSC Certified Materials (optional) |

| Production Time | 7–14 Business Days after artwork approval |

| Shipping | Global Delivery, Custom Export Packing, Palletized or Carton Options |

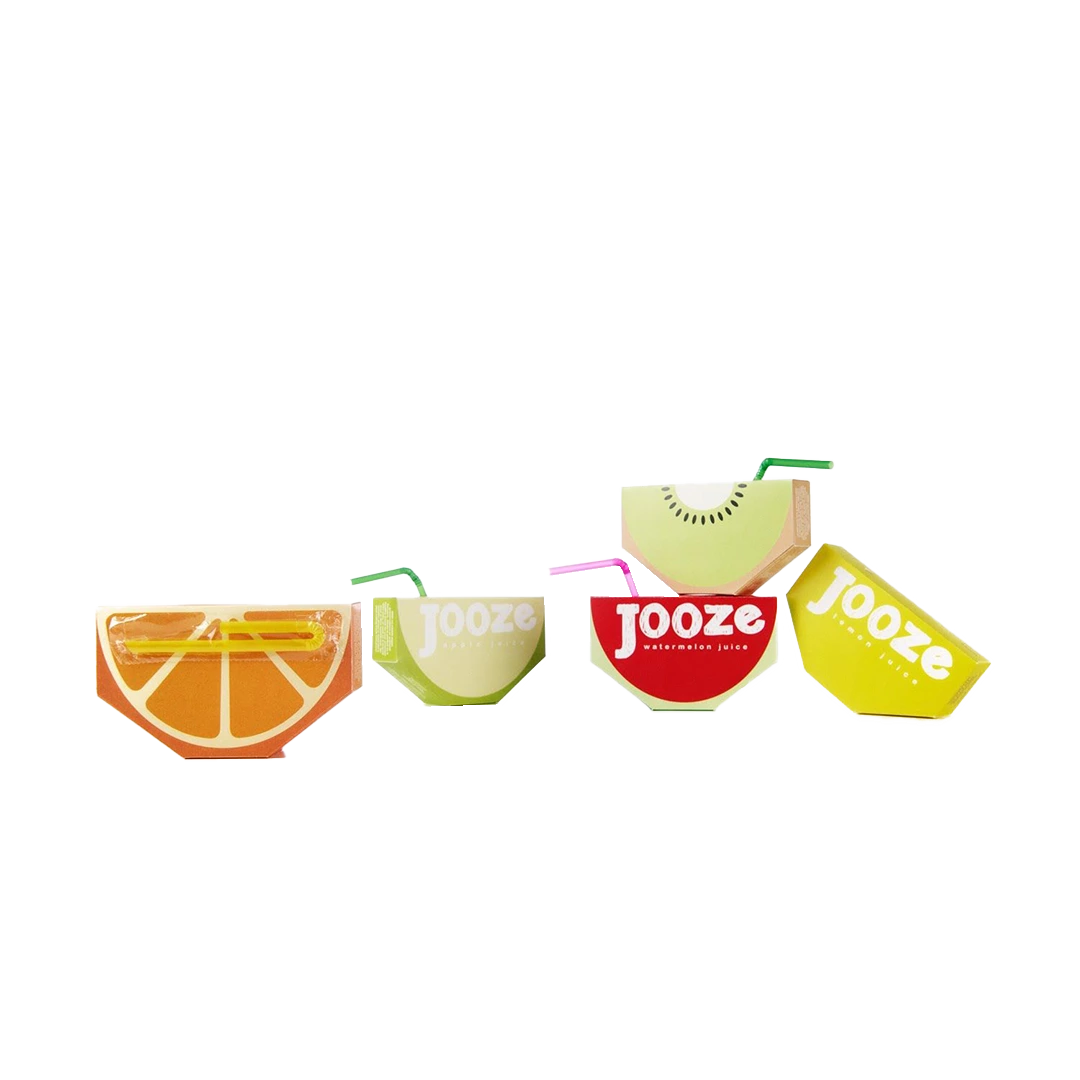

Fruit Shaped Juice Boxes

Fruit shaped juice boxes offer creative design and innovative look of apples, oranges, strawberries and grapes. Such boxes quickly grab the eye of the consumer, making them ideal for companies wanting to reach children, schools and events that focus on health. Strong and colourful pictures on bottles bring the design and taste of the juice close together. The Product Boxes UK offer tempting and useful custom fruit-shaped juice boxes for our customers. We ensure the materials we use are safe for eatables and assist your brand in reaching its environmental goals.

The packaging boxes can be made to your own specifications with full-colour printing, logos and other visual components. Each serving of juice fits in its own box and they are perfect for school lunches, party treats or promoting a business. As well as being fun to look at, our personalised product boxes are made to prevent spills and are durable enough to survive a full meal. Contact us to get the packaging that shares your brand’s look and feel, on the outside and inside.

Starting From: £0.84 Per Box

Available in Stock

Q. What materials are used to make Fruit Shaped Juice Boxes?

Q. Are these juice boxes safe for direct food contact?

Q. Can I get my brand logo printed on the juice boxes?

Q. Are eco-friendly or recyclable versions available?

Q. What shape and fruit styles can I choose from?

Q. Are these boxes suitable for kids’ drinks or school packaging?

Q. Can the juice boxes include straws or spouts?

Q. Do these boxes retain freshness and prevent leakage?

Q. What is the minimum order quantity for custom designs?

Q. How long does production and shipping usually take?

Get an instant quote

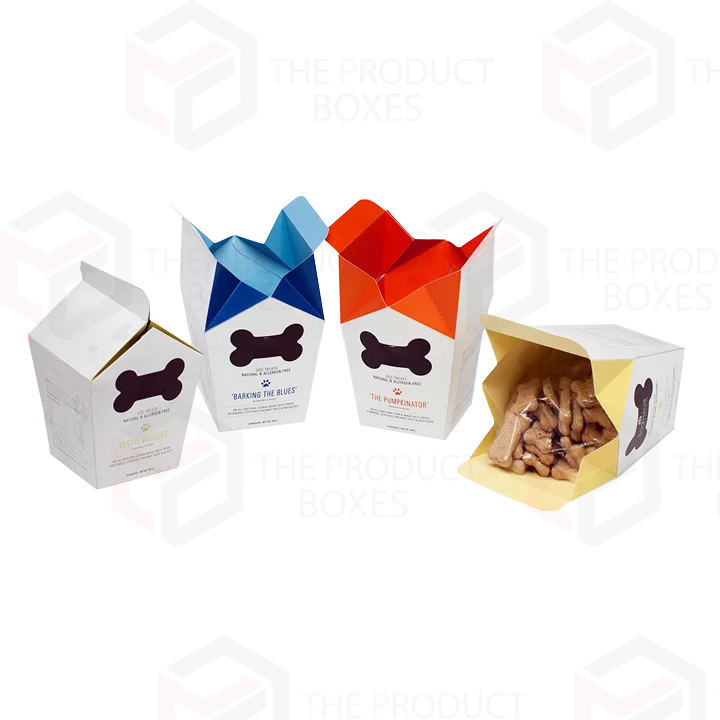

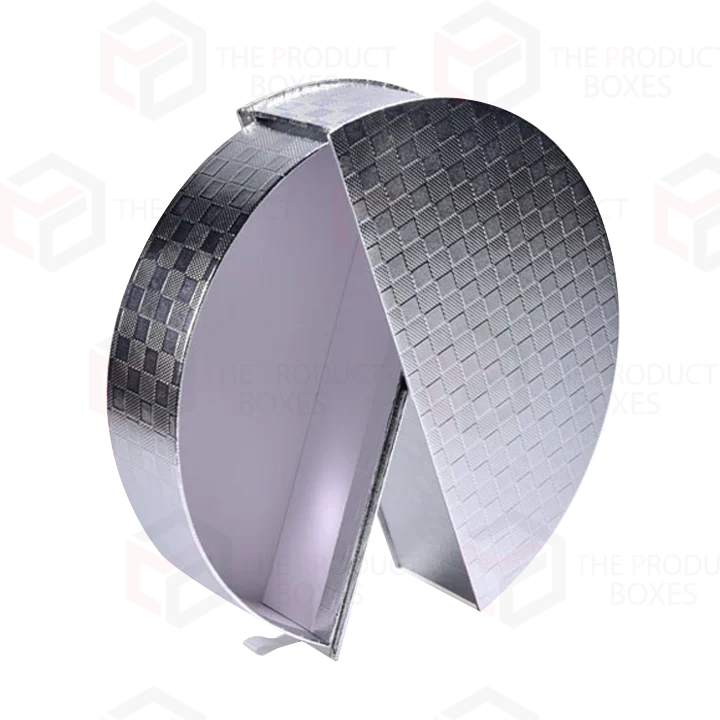

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.