| Type | Specification |

|---|---|

| Material | Premium Kraft Paper, Recycled Kraft Board, Corrugated Kraft, Virgin Brown Kraft |

| Box Styles | Auto-Lock Bottom, Reverse Tuck, Straight Tuck, Two-Piece, Mailer, Sleeve, Pillow, Display |

| Printing | CMYK, PMS, Digital, Offset, Screen Printing, UV Printing |

| Finishing Options | Matte, Glossy, Soft-Touch, Embossing, Debossing, Spot UV, Aqueous Coating |

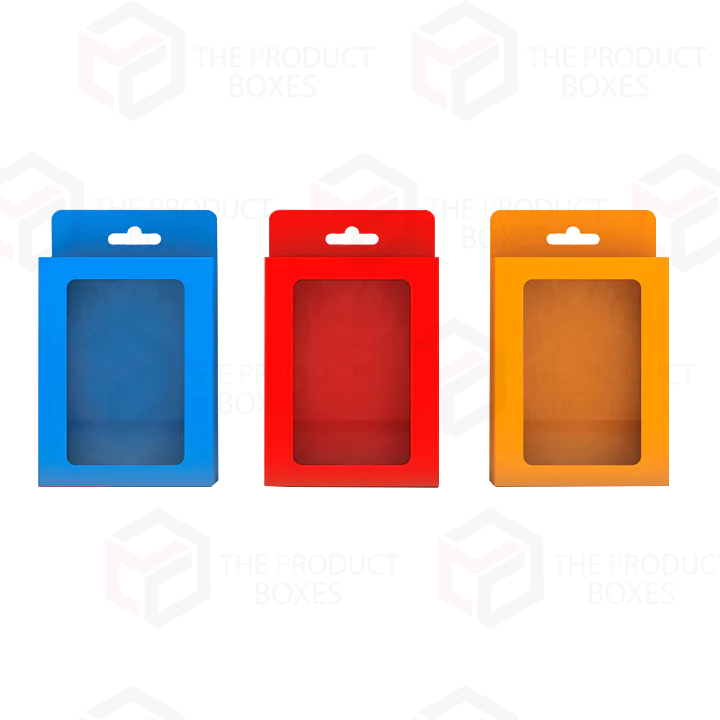

| Customization | Die-Cut Windows, PVC Windows, Perforation, Hang Tabs, Custom Inserts |

| Sizes | Fully Customizable – Small, Medium, Large (As per product dimensions) |

| Thickness | 12pt, 14pt, 16pt, 18pt, 20pt, 22pt, 24pt Kraft Paperboard |

| Printing Add-Ons | Foil Stamping (Gold, Silver, Holographic), Embossing, Debossing, Raised Ink |

| Closure Types | Snap-Lock, Magnetic, Ribbon Closure, Self-Locking, Foldable |

| Eco-Friendliness | 100% Recyclable, Biodegradable, Sustainable, FSC Certified |

| Logos & Branding | Custom Printed, Hot Stamped, Embossed, Debossed, UV-Coated |

| Minimum Order Quantity | As low as 100 boxes (Custom bulk ordering available) |

| Usage | Retail Packaging, Food Packaging, Cosmetics, Apparel, Subscription Boxes, E-Commerce |

| Additional Features | Hinged Lids, Magnetic Flaps, Custom Cut-Outs, Foldable Inserts |

| Shipping Options | Flat Packed, Pre-Assembled, Bulk Stacking Available |

| Production Time | 7-12 Business Days (Rush Orders Available) |

Kraft Product Boxes

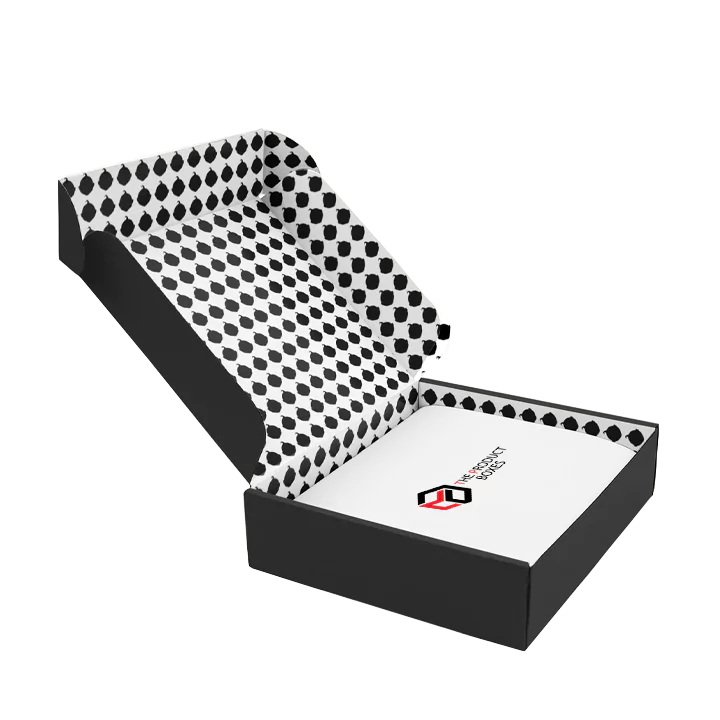

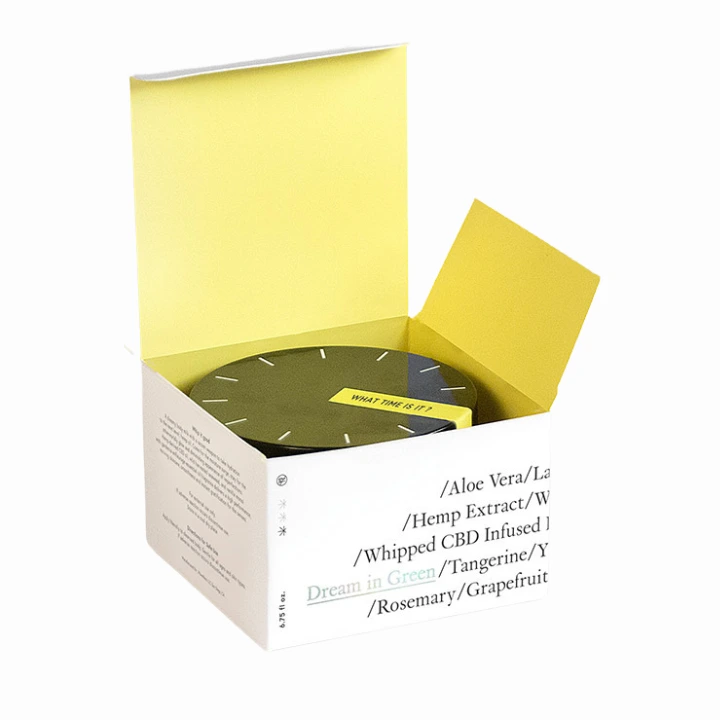

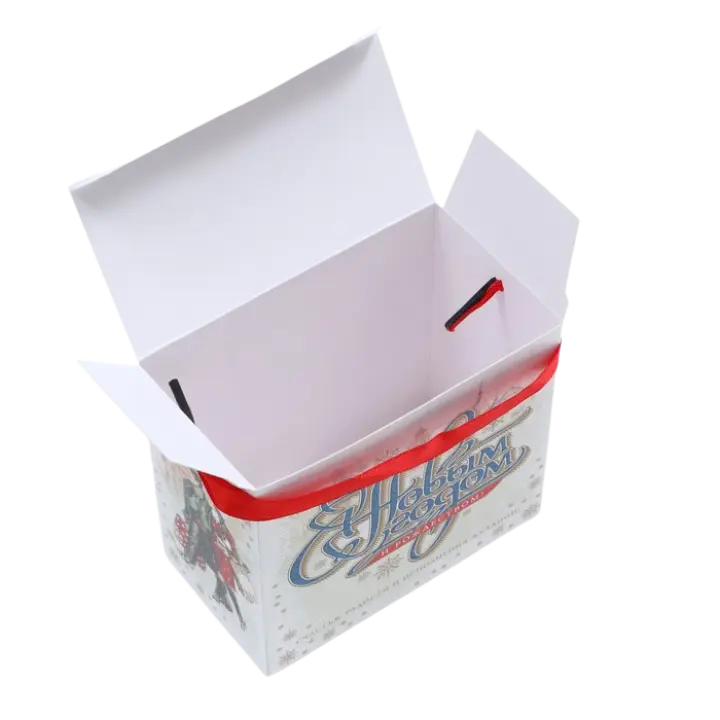

Exquisite design and all the cost-cutting features make Kraft product boxes an effective packaging solution. These boxes are great for cosmetics, food, apparel, and electronics industries, providing an eco-friendly packaging option. Their natural brown colour gives these boxes a rustic appearance, which is ideal for brands that want to portray elegance. The Product Boxes UK is specialised in designing custom kraft product packaging to suit your specifications.

We ensure the perfect branding starting from simple kraft packaging to elaborate designs. Different brands require different sizes, shapes, and finishing options like custom product boxes with logo, embossed or foil stamped, die-cut windows, or print designs. In order to meet the demand of businesses looking for bulk packaging, we provide kraft paper packaging wholesale at economical rates, making it a great alternative for economical yet premium packaging solutions. So, don’t wait and elevate your product’s packaging to something sustainable. Contact The Product Boxes UK today to get customised kraft boxes that go with your business branding.

Starting From: £0.49 Per Box

Available in Stock

Q. What materials are used to make Kraft Product Boxes?

Q. Can I customize the size and shape of Kraft Product Boxes?

Q. What printing options are available for Kraft Product Boxes?

Q. Are Kraft Product Boxes eco-friendly and recyclable?

Q. Can I get Kraft Product Boxes with a die-cut window?

Q. What finishing options are available for Kraft Product Boxes?

Q. Can I add my logo and branding to Kraft Product Boxes?

Q. Can I order Kraft Product Boxes in bulk?

Q. Do you provide sample boxes before bulk production?

Q. What industries use Kraft Product Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.