| Type | Specification |

|---|---|

| Product Name | Custom Liquid Lipstick Boxes |

| Primary Material | SBS paperboard, Kraft, corrugated board, rigid chipboard (optional) |

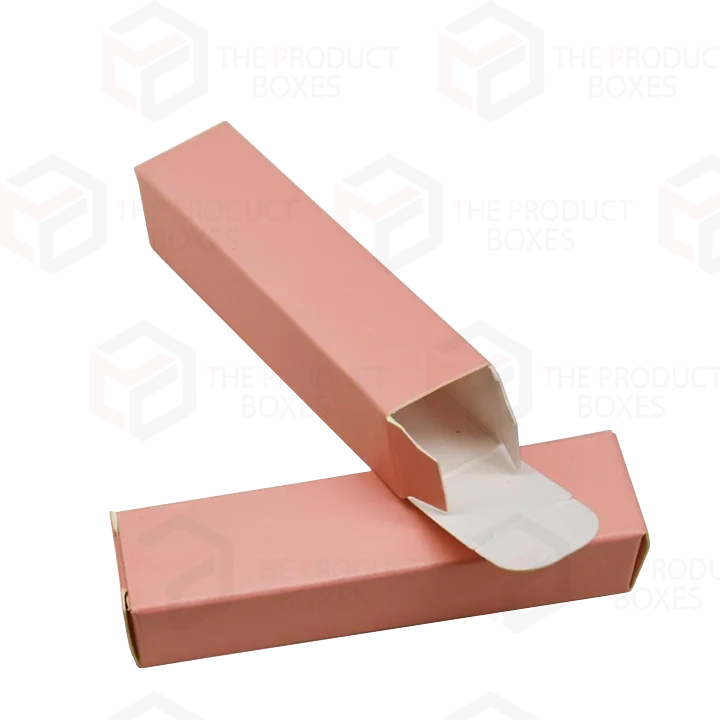

| Box Styles | Straight tuck-end, reverse tuck-end, auto-lock bottom, sleeve with tray, two-piece rigid |

| Thickness Range | 14pt, 16pt, 18pt, 20pt (paperboard); up to 32pt for rigid |

| Printing Method | Offset, digital, UV, litho-lamination |

| Color Options | Full CMYK, Pantone (PMS), metallic inks, solid base shades |

| Finishes | Matte, gloss, soft-touch lamination, aqueous coating, anti-scratch |

| Brand Logo | Printed, embossed, debossed, hot foil stamped, or spot UV |

| Inserts (Optional) | Custom die-cut cardboard, foam, or molded pulp inserts |

| Box Dimensions | Tailored to liquid lipstick tube size; typically narrow and tall (custom-fit) |

| Window Option | Die-cut display window with or without clear PVC film |

| Surface Texture | Silk smooth, textured linen, velvet-touch (on request) |

| Eco Options | Recycled paperboard, FSC-certified kraft, biodegradable inks |

| Use Cases | Retail display, influencer kits, beauty subscriptions, shelf-ready packaging |

| Quantity Range | MOQ 100 units, bulk and wholesale options available |

| Assembly Type | Flat-packed or pre-glued (depending on structure) |

| Customization Options | Full customization of material, size, print, insert, coating, logo, cut-out, and style |

| Lead Time | 7–10 business days standard; rush options available |

Liquid Lipstick Boxes

Liquid lipstick packaging plays a crucial role in protecting the product as well as presenting the brand in the competitive beauty market. The Product Boxes UK offer custom liquid lipstick boxes design, to make your product more attractive and also safe to handle, ship and display in stores. Specifically designed to fit the thin, fragile shape of liquid lipstick tubes, these boxes are created using durable materials, such as cardstock, corrugated, or rigid board, to withstand damage or leakage. We can customise everything: dimensions, structure, finishes, and the visual details.

High-end matte or gloss finishes, spot UV, foil stamping, embossing, and window cut-outs to reveal the product within are all options available to you. We use printing technology that produces clear logos, vibrant colours, and high-quality visuals that represent your brand. These custom lipstick boxes can also be made eco-friendly in case the brands are focused on sustainability. Our packaging is ideal whether it is on retail shelves, subscription box, or online delivery. We specialises in creating eye-catching, sturdy, and affordable lipstick boxes that will create a lasting impression.

Starting From: £0.50 Per Box

Available in Stock

Q. What is the best packaging box for liquid lipstick bottles?

Q. How do custom lipstick boxes help with brand recognition?

Q. Can liquid lipstick boxes be designed for glass bottles?

Q. What type of insert is best for lipstick bottle packaging?

Q. How thick should lipstick packaging boxes be for safety?

Q. Where can I order custom boxes for liquid lipstick in the UK?

Q. What are the standard dimensions for liquid lipstick boxes?

Q. What box styles are available for lipstick packaging?

Q. What shapes can Liquid Lipstick Boxes be made in?

Q. Can I include a window or transparent panel?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

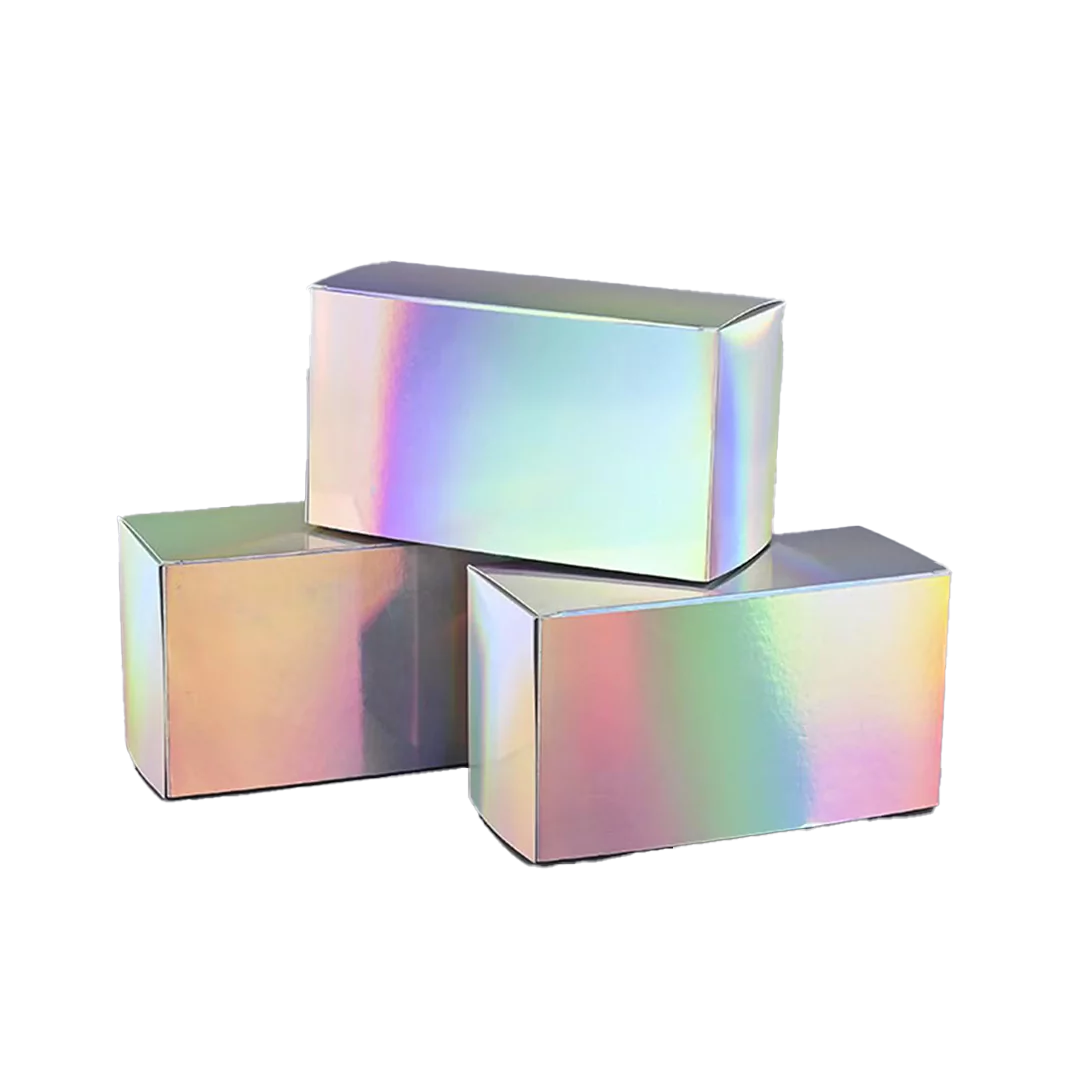

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.