| Type | Specification |

|---|---|

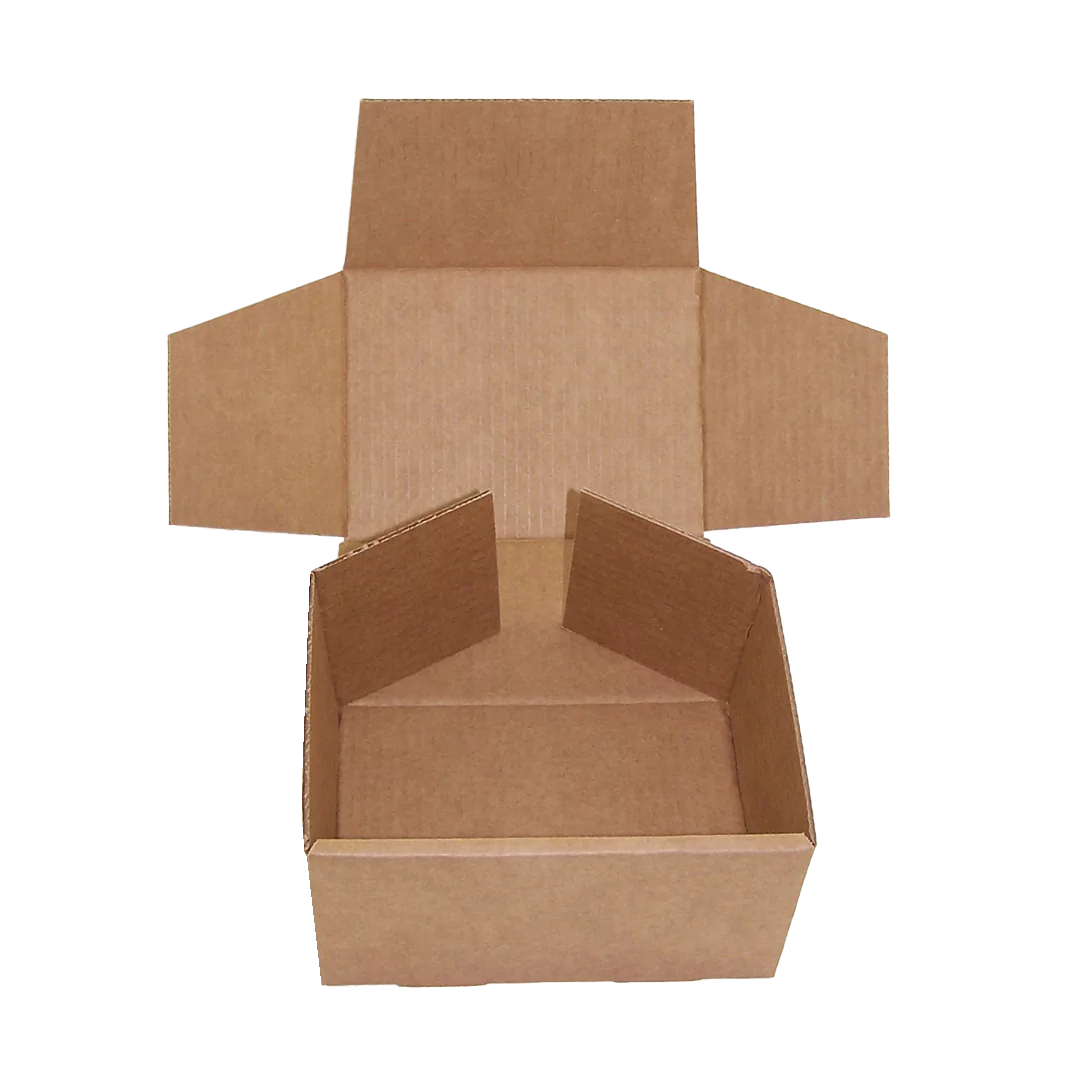

| Box Style | Self-locking mailer with dust flaps and front tuck closure |

| Material | E-flute or B-flute corrugated cardboard with white, kraft, or premium black liners |

| Colour Options | Matte Black base (inside/outside), full-colour CMYK or Pantone available on request |

| Finish | Matte, Soft-Touch, Anti-Scratch Matte, Satin, or UV Coating |

| Printing | Offset, Digital, or Flexographic with optional foil stamping, embossing, or debossing |

| Logo & Branding | Custom logo printing (exterior & interior), foil-stamped or embossed logos available |

| Sizes | Custom sizes available – e.g., 9x6x2″, 10x8x4″, 12x9x4″ – based on product fit |

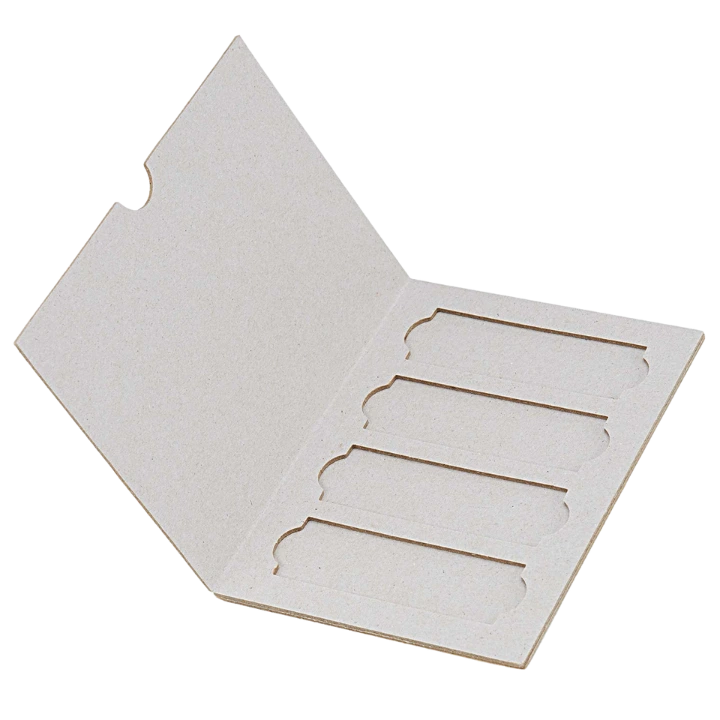

| Inserts | Die-cut cardboard, foam inserts, paperboard dividers, or fabric lining |

| Interior Printing | Available – logos, patterns, instructions, or full-colour graphics |

| Coating Options | Gloss AQ, Matte AQ, Soft-Touch Lamination, UV Spot, or Varnish |

| Closure Type | Standard front tuck flap with optional magnetic or adhesive seal on request |

| Custom Quantity | MOQ from 50 units, bulk runs available in 100s to 1000s |

| Eco-Friendly Options | FSC® certified board, soy-based inks, recyclable and biodegradable materials |

| Turnaround Time | Standard 7–12 business days, rush orders available |

| Applications | Ideal for electronics, apparel, subscription kits, promotional gifts, and luxury goods |

Matte Black Mailer Boxes

With their sleek design and sturdy construction, matte black mailer boxes are a perfect fit for packaging needs. They are ideal for brands looking to stand out and keep their look sleek and premium. These boxes are strong and come in matte finish, great for shipping, retail use and subscription boxes. The appearance of natural matte colour helps your items look elegant on the shelf, avoiding the need for over complicated designs.

You have the option to customise your mailers made by The Product Boxes UK with your logo, graphics and branding marks using special printing techniques such as foil stamping and UV spot coating. Made from materials that can be recycled, they are not hazardous to the environment. No matter if you ship luxury cosmetics, tech gadgets, apparel or artisan products, postal boxes wholesale option show that your packaging is top quality. We enables companies of any size to get custom packaging, making their products attractive and useful.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Matte Black Mailer Boxes?

Q. Are Matte Black Mailer Boxes customisable?

Q. Can I print my logo or artwork on Matte Black Mailer Boxes?

Q. Are Matte Black Mailer Boxes suitable for shipping?

Q. What sizes are available for Matte Black Mailer Boxes?

Q. What finish options are available for these boxes?

Q. Are these boxes eco-friendly?

Q. Can I include inserts or internal printing?

Q. What is the minimum order quantity for Matte Black Mailer Boxes?

Q. How long does it take to produce and deliver Matte Black Mailer Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.