| Type | Specification |

|---|---|

| Material | Food-grade Kraft, White Cardboard (SBS), Corrugated Board, Coated Paperboard |

| Coating | Gloss AQ, Matte AQ, PE Coating (Leak-Proof), Oil-Resistant Liner |

| Printing | CMYK, Pantone (PMS), UV Printing, Flexographic, Digital |

| Logo Application | Custom Logo Printed, Embossing, Debossing, Foil Stamping (Gold/Silver) |

| Colour Options | Full-Color Custom Printing, Inside & Outside Print Available |

| Standard Sizes | 8oz, 12oz, 16oz, 26oz, 32oz (Custom Dimensions Available) |

| Structure | Foldable with Locking Flaps, Automatic Bottom, Tab Lock Top |

| Window Option | Optional Die-Cut PET Window with Anti-Fog Coating |

| Custom Inserts | Optional Paperboard or PET Inserts for Sectioning or Sauce Holders |

| Microwave Safe | Available with PE Coated Lining for Microwave Use |

| Usage | Takeout, Fast Food, Asian Cuisine, Catering, Food Delivery |

| Quantities | MOQ 100 – Bulk Quantities up to 100,000+ Units |

| Packaging Style | Flat-Packed or Pre-Assembled (Based on Request) |

| Finish Options | Gloss Lamination, Matte Lamination, Soft Touch, Uncoated |

| Custom Features | QR Codes, Nutrition Panels, Barcodes, Brand Messaging |

| Sustainability | 100% Recyclable, Compostable Materials, Soy-Based Inks |

| Lead Time | 7–10 Business Days (After Design Approval) |

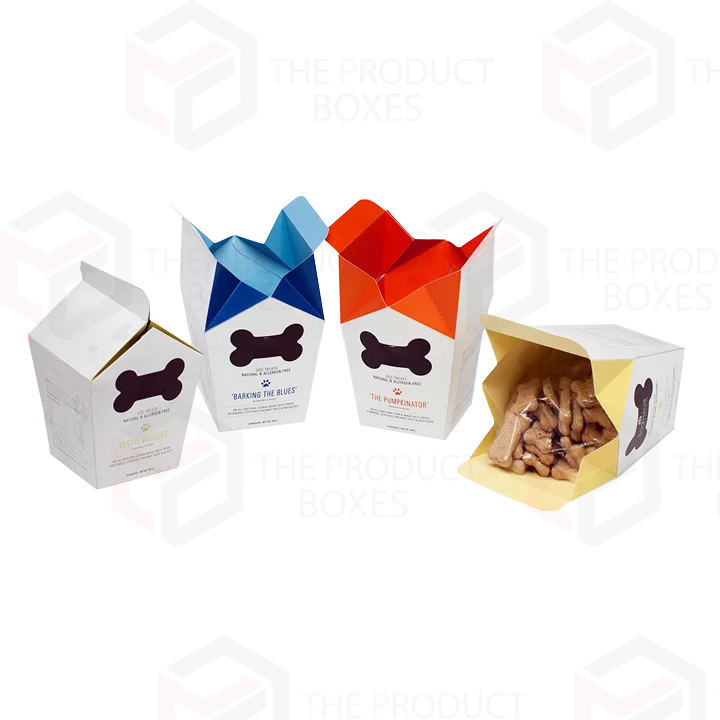

Personalised Noodle Boxes

By offering personalised noodle boxes, takeout restaurants, stalls and catering companies can improve their brand image as well as make their packaging more useful. The Product Boxes UK allow their customers to choose custom takeaway boxes with personalised design. Get unlimited options including your logo, usual colours, tagline or offers to make the entire experience pleasant. All our chinese food boxes are crafted to prevent leaks and keep foods warm, making them suitable for any spicy or saucy Asian dish.

At The Product Boxes UK, we offer custom noodle boxes are made using food-grade materials and high-quality printing so that they are visually appealing and able to perform well. So, if you need to get durable and eco-friendly noodle boxes for dine-in, takeaway or delivery, our comprehensively branded boxes are a good choice. Contact us to avail wholesale price and free delivery service.

Starting From: £0.67 Per Box

Available in Stock

Q. What materials are used to make Personalised Noodle Boxes?

Q. Are these noodle boxes safe for hot and oily foods?

Q. Can I get my restaurant logo or design printed on the boxes?

Q. Do you offer eco-friendly or recyclable noodle box options?

Q. Can I order custom sizes and shapes for my noodle boxes?

Q. Are these boxes microwave-safe?

Q. What is the minimum order quantity (MOQ) for personalised noodle boxes?

Q. Do the boxes come assembled or flat-packed?

Q. Can you include QR codes or nutritional labels on the packaging?

Q. What is the average production and delivery time?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

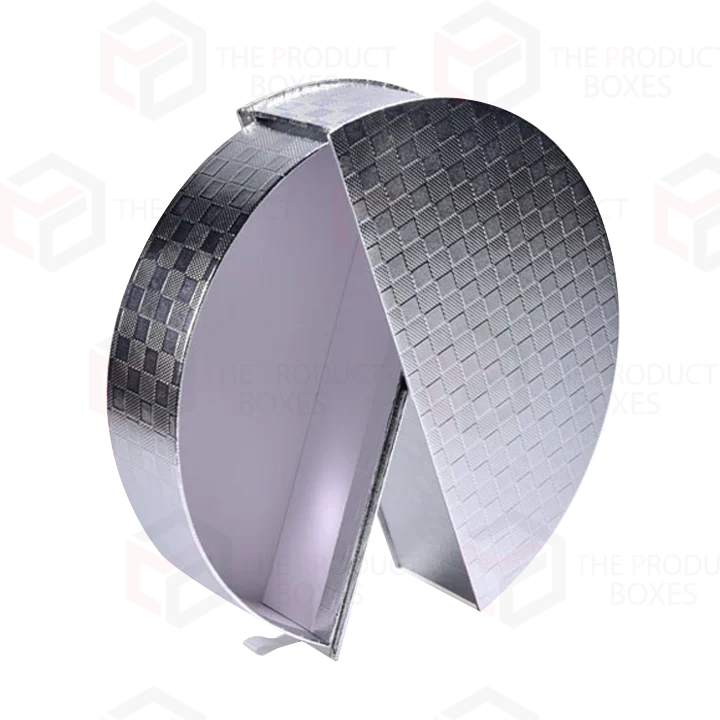

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.