| Type | Specification |

|---|---|

| Material | Rigid chipboard, premium cardboard, kraft, and greyboard |

| Printing | CMYK, PMS, digital and offset printing available |

| Logo | Custom logo with embossing, debossing, foil stamping, UV spot |

| Colour Options | Custom colours including full Pantone & CMYK palettes |

| Size | Made to order – fully custom dimensions |

| Box Style | Magnetic closure, two-piece, drawer, hinged lid, sleeve |

| Inserts | Foam, EVA, paperboard dividers, fabric-wrapped trays |

| Finish | Gloss, matte, soft-touch lamination, AQ coating, UV varnish |

| Window Option | Die-cut or clear PVC window (custom shape) |

| Eco Features | Recyclable, biodegradable, FSC-certified stock, soy ink |

| Quantity | Custom MOQ starting from 100 units |

| Sampling | Digital mockup & physical sample on request |

| Turnaround | Standard: 8–12 business days after approval |

| Use | Luxury candy packaging, gifting, retail shelf display |

Rigid Candy Boxes

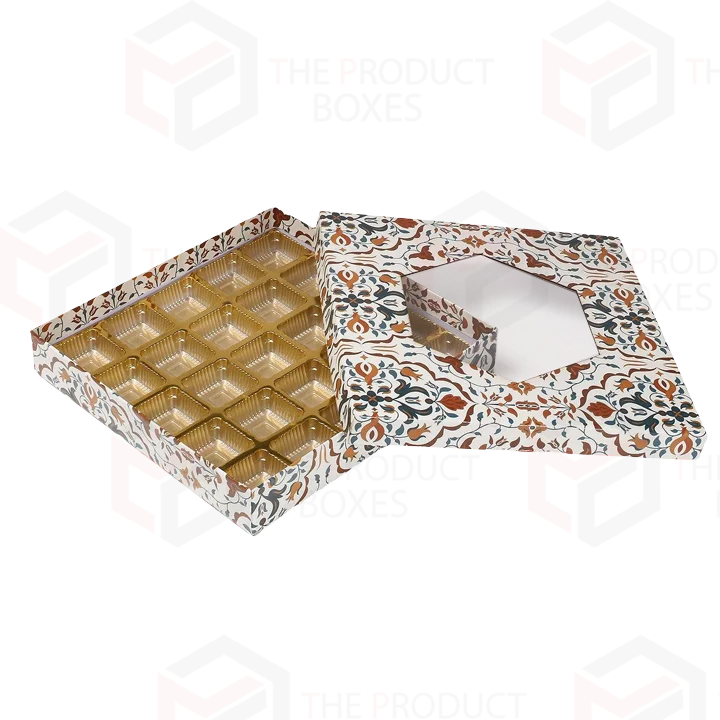

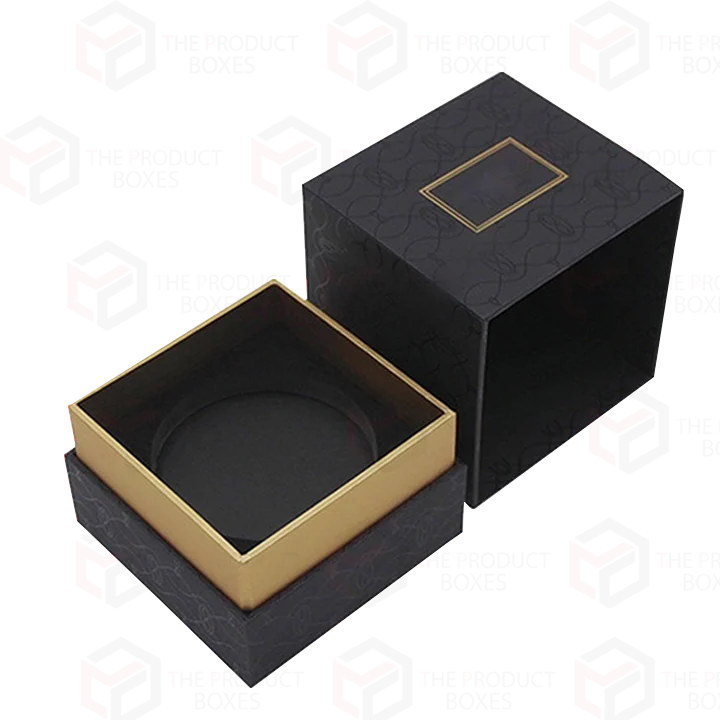

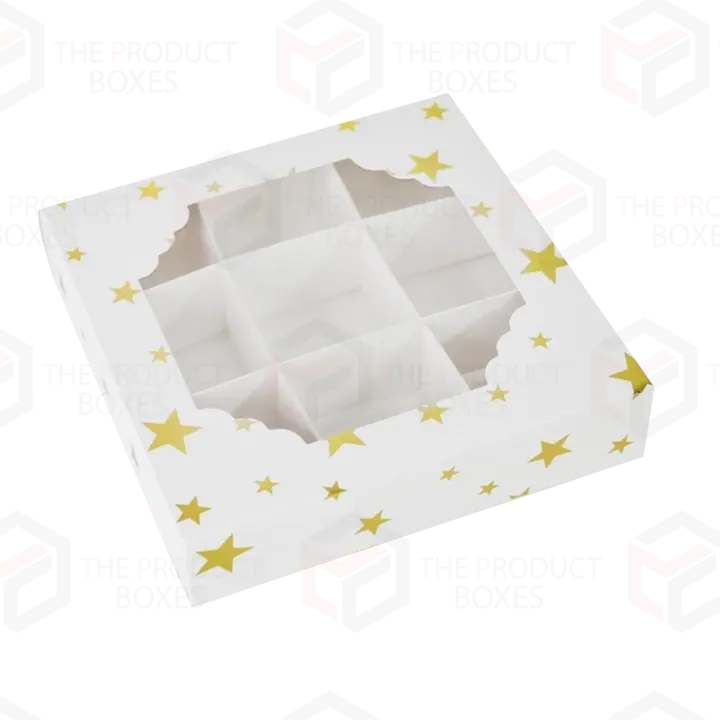

Packaging rigid candy boxes from The product boxes UK create perfect presentations for your confections through their elegant construction, making them suitable for upscale gift giving. Luxury-seeking customers show preference for solid rigid boxes to safeguard their high-end chocolates and fancy sweet treats such as truffles and bonbons. The Product Boxes UK make custom candy boxes from robust chipboard that uses premium paper stocks which customers can select from various dimensions and colour options. Your packaging will achieve personalisation through various enhancements that include foil stamping, embossing and debossing combined with ribbon closures as well as magnetic lids or die-cut windows.

The food-safe interior design and inserts from our company provide a secure packaging method which keeps candies protected and beautifully showcased. bespoke paper over board boxes serve as excellent presents while enhancing retail display because they unite durable construction with attractive design. We, at TPB, provide product packaging wholesale solutions for businesses which enables them to expand their operations while maintaining premium aesthetics. Reach us today for rigid box packaging UK and enhance your brand image while creating joy in every delivery.

Starting From: £1 Per Box

Available in Stock

Q. What materials are used to make Rigid Candy Boxes?

Q. Can I customise the size of Rigid Candy Boxes?

Q. Are these boxes suitable for luxury candy packaging?

Q. What insert options are available inside Rigid Candy Boxes?

Q. Can I print my brand logo on Rigid Candy Boxes?

Q. Are eco-friendly materials used in these boxes?

Q. Can I get Rigid Candy Boxes with a window?

Q. What closure styles are available?

Q. What is the minimum order for Rigid Candy Boxes?

Q. Can I request a sample before bulk order?

Q. How long does production take?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.