| Type | Specification |

|---|---|

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 4-6 Business Days, Rush |

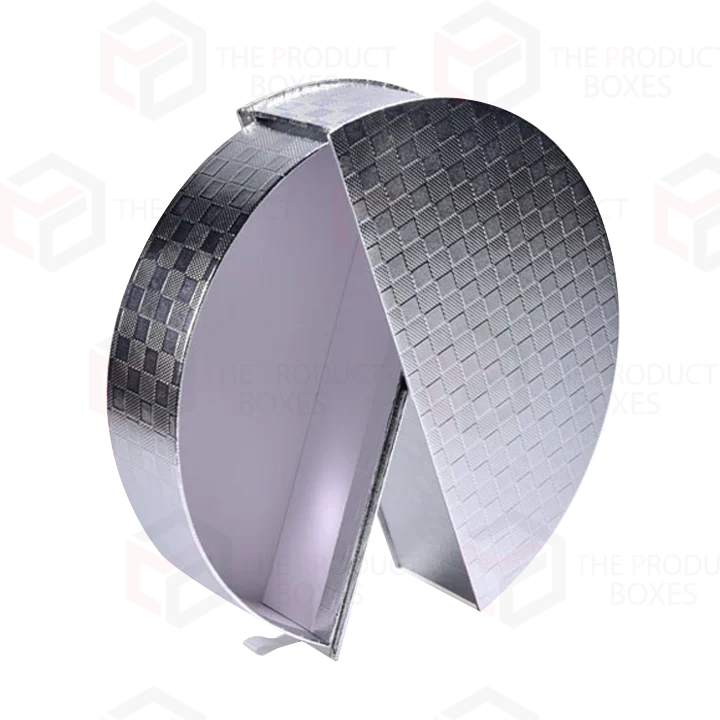

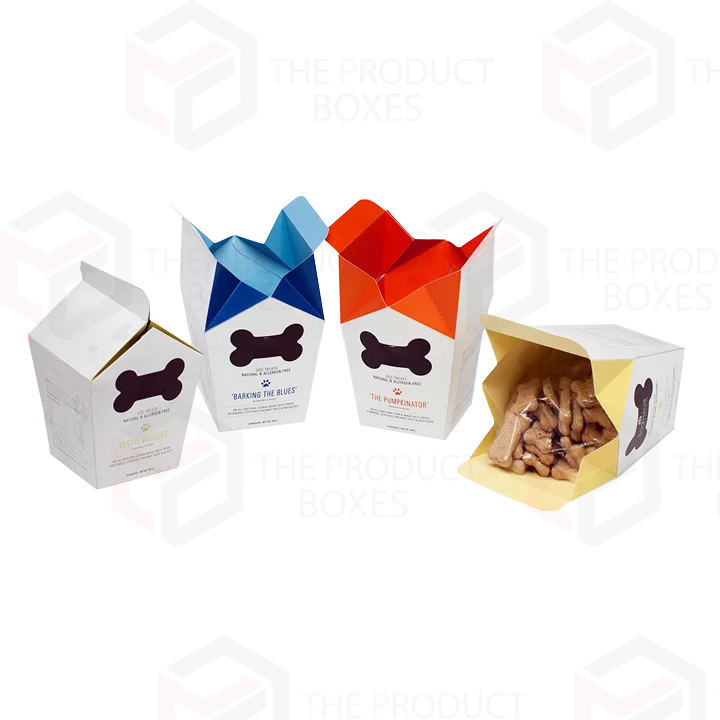

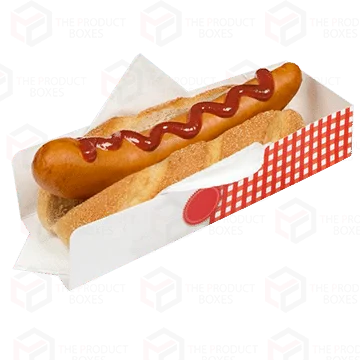

Rigid Food Packaging

Rigid food packaging is important for reliable protection of a wide range of food items to keep them secure and fresh during display storage or handling. Our rigid paper food packaging boxes not only preserves the quality of food but also increases the overall presentation with personalisation. The durable, high- quality material and thick cardboard paper is best for chocolates, snacks, baked goods or confectionery. The material maintains the structure and shape of boxes by providing great protection against moisture and external factors. Customisation is the key of our packaging and we offer a variety of styles and sizes.

It also allows your custom food boxes to stand out in the competitive market and attract more customers. These food packaging boxes not only ensure durability but also prioritise hygiene. We always prefer food- safe material to keep the product uncontaminated. Additional features are also available including compartments, inserts, and window cut-outs to keep the multiple items organised in the same box. Contact us today and order custom rigid boxes uk to boost up the overall presentation of your product.

Starting From: £1 Per Box

Available in Stock

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.