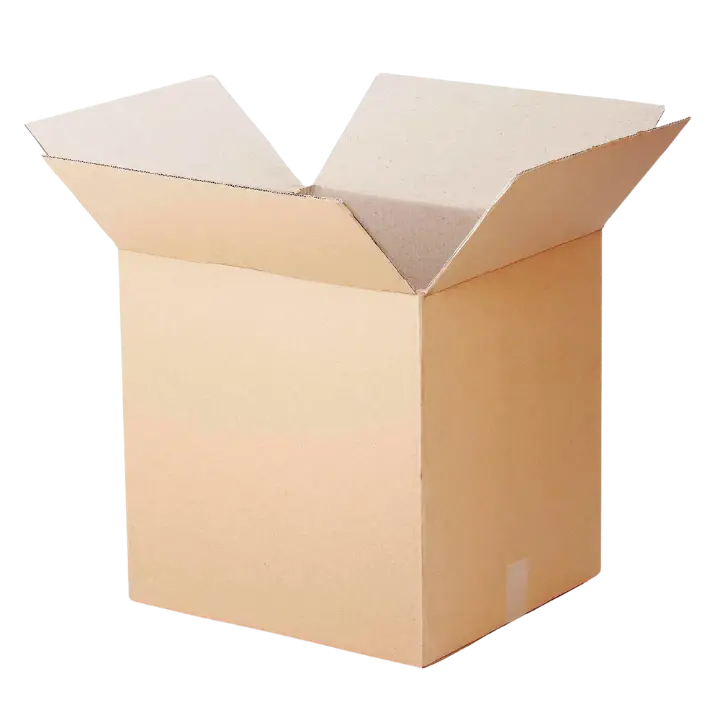

| Type | Specification |

|---|---|

| Material | Double Wall Corrugated Board (Flute: BC/E/E+B) |

| Wall Structure | Two layers of fluted paperboard between three liners |

| Box Strength | Heavy-duty compression resistance for fragile or heavy contents |

| Box Style | 0201 Regular Slotted Container (RSC) or Die-Cut Custom Style |

| Sizes | Customisable; standard sizes from 6″ x 6″ x 6″ to 18″ x 18″ x 18″ |

| Colour Options | Brown Kraft, White Kraft, or full-colour CMYK printing |

| Logo Printing | Custom logo options: screen print, digital print, or flexographic |

| Surface Finish | Matte, Gloss, UV Coating, or Eco-friendly Water-Based Varnish |

| Quantity | Minimum Order: 100 units (bulk and wholesale available) |

| Printing Options | Offset, Digital, Flexo, and Silkscreen Printing |

| Use Cases | Shipping, eCommerce Packaging, Heavy Product Transport |

| Load Capacity | Supports up to 30-50 kg depending on dimensions and flute type |

| Custom Inserts | Available: Cardboard dividers, foam inserts, kraft fillers |

| Eco-Friendliness | Made from 60-90% recycled content; 100% recyclable |

| Assembly | Delivered flat-packed; easy manual or automated assembly |

Small Double Wall Boxes

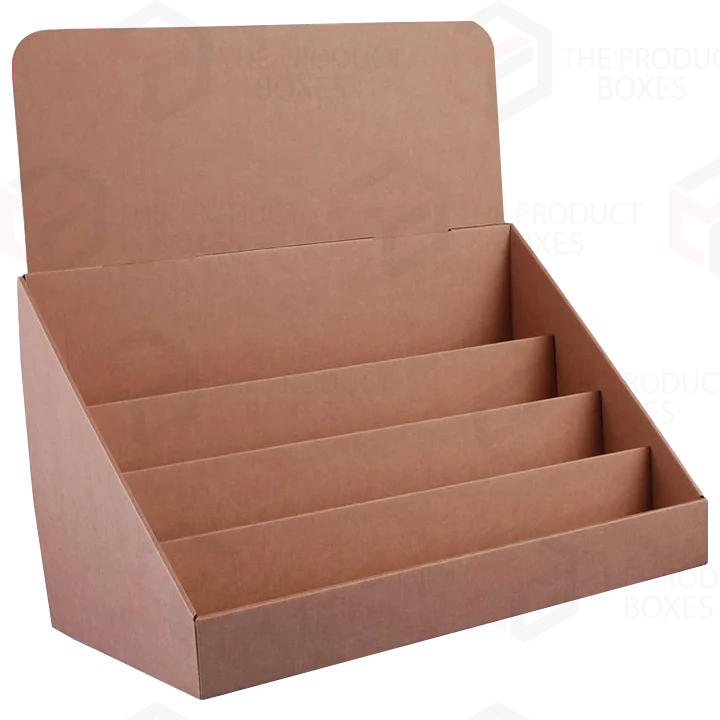

Stock your goods with safety in small double wall boxes offered by The Product Boxes UK. Robust boxes provide strong security benefits that fit retail products and very valuable or delicate items for protecting them through storage and shipment. Premium-quality cardboard is used for crafting these double wall boxes, incorporating two thick protective layers for maximum durability against impacts. The boxes work correctly for sending e-commerce orders, retail solutions as well as serving as gift boxes. Our boxes allow you to customise the overall appearance through your brand logo, artwork and personalised brand colours so you can establish your professional brand with every shipping delivery. They offer several dimensions which make them suitable for protecting electronics and cosmetics as well as compact retail products.

Our company provides small parcel boxes wholesale rates with minimum order requirements to help your business expand effectively. The Product Boxes UK is ready to help you design strong and secure small double wall boxes that enhance your brand image.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Small Double Wall Boxes?

Q. What are the standard sizes available for Small Double Wall Boxes?

Q. Can I request custom printing or branding on Small Double Wall Boxes?

Q. What colour options are available for Small Double Wall Boxes?

Q. What is the minimum order quantity (MOQ) for Small Double Wall Boxes?

Q. Are these boxes suitable for international shipping?

Q. Can I get these boxes with die-cut handles or windows?

Q. What quantity can be delivered in bulk or wholesale orders?

Q. Are inserts or dividers available for Small Double Wall Boxes?

Q. How long does it take to manufacture custom Small Double Wall Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.