Versatile Custom Stress Ball Packaging Boxes to Maximise Your Brand Impact

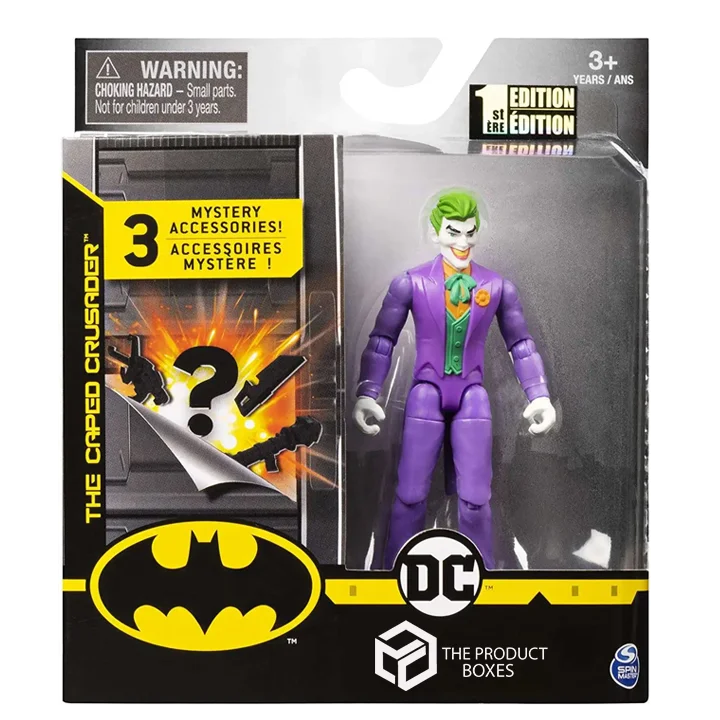

Stress balls are one of the popular items famous for stress relieving properties. These are used in homes, offices as well as educational institutions. In order to ensure that stress relieving products reach their customers in the best condition, packaging plays an essential role. At The Product Boxes, stress ball boxes are significantly designed to maintain the shape as well as protect the product from external damages. These boxes are an effective marketing tool to increase the brand’s images.

We understand the importance of packaging that reflects your brand image. For this purpose, we offer personalised stress ball packaging boxes to fulfill the unique requirements of customers. No matter if you need a particular size, shape or design, customisation is important to create the perfect packaging solutions for your brand.

Innovative Stress Relief Toys Packaging; Options for Every Need

The Product Boxes offer multiple types of stress ball packaging boxes to fulfill the diverse needs and preferences of the customers. However, some of the most common packaging boxes are:

- Window boxes

- Display boxes

- Custom shape boxes

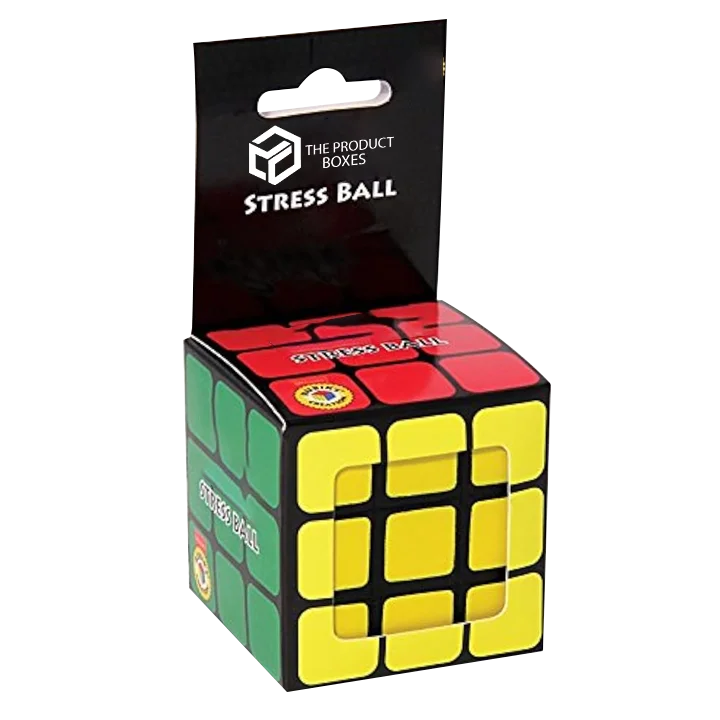

Window boxes:

Our window boxes come with transparent windows that allow you to see the stress ball inside without opening the box. These boxes are best to increase the visual appeal of the shelf.

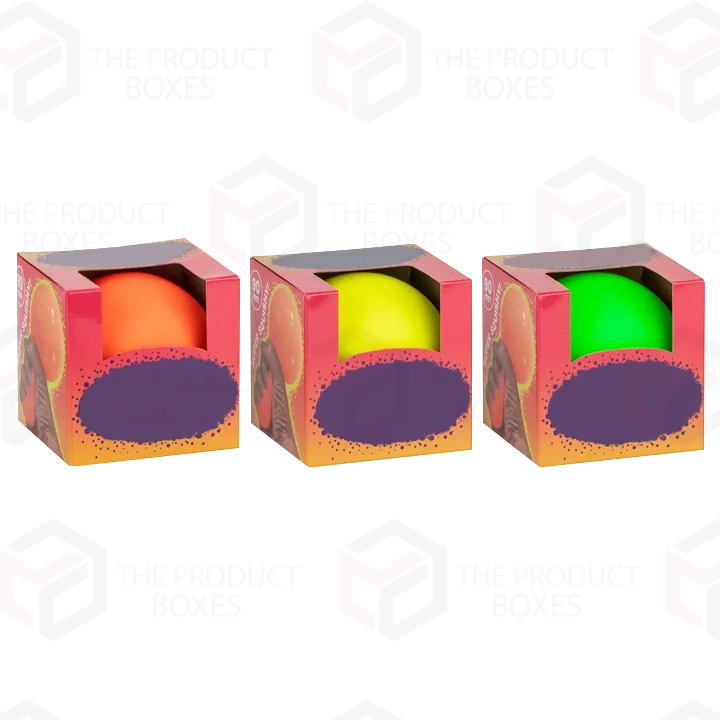

Display boxes:

Display boxes are significantly designed to show stress balls for display purpose as well as for promotional events. These boxes provide easy accessibility and visibility to the customers.

Custom shape boxes:

Custom shaped stress ball boxes are designed according to the unique shape of the stress ball. These boxes offer snug fit for maximum protection.

Transform Your Packaging With Our Customisation Techniques

In order to make the stress ball packaging appealing and stand out, The Product Boxes offer multiple customisation options. These customisation techniques include:

- High quality printing options to create detailed and vibrant designs

- Elegant finishing with matte or glossy finish and UV coating experience

- Create unique shapes and designs with precision die cutting

- Enhances the visual appeal of boxes with metallic foiling in silver or gold colour for a luxurious touch

Contact TPB For Wholesale Stress Ball Packaging

If you’re a business owner and want to order in bulk, The Product Boxes offer a wholesale stress ball packaging solution without compromising on quality. Our wholesale option ensures that you’ll get the best value for money. No matter if you are a retailer or distributor, we’re here to fulfill large order requirements efficiently.

So, are you ready to order your stress ball packaging boxes? Contact The Product Boxes today and get started on creating a custom packaging solution. Our team of experts will help you every step of the way. So don’t wait and choose us to know how we help you to achieve your toy packaging goals.