| Type | Specification |

|---|---|

| Product Name | White Bakery Boxes with Window |

| Material Options | Premium white SBS board, food-grade Kraft, or corrugated micro-flute |

| Board Thickness | 250–500 GSM (single or double wall depending on product weight) |

| Window Material | Transparent PET, PLA, or acetate film (food-safe, recyclable) |

| Colour Tone | Classic white or custom tinted with Pantone colour accuracy |

| Surface Finish | Gloss, matte, soft-touch, or satin laminated coating |

| Printing Process | Offset, digital, CMYK or PMS colour system with UV precision |

| Logo & Branding | Embossing, debossing, foil stamping, or screen-printed logo integration |

| Coating Options | Aqueous, UV spot, or food-safe non-toxic varnish |

| Die-Cut Precision | Laser-cut windows with high accuracy and clean edges |

| Shape & Style | Rectangular, square, or fold-top with window pane configuration |

| Closure Type | Tuck-end, auto-lock base, or snap-lock flaps for secure seal |

| Custom Sizes | Available for cupcakes, pastries, doughnuts, cakes, and assorted bakery items |

| Eco Certification | FSC® approved, biodegradable, and 100% recyclable materials |

| Window Shape Options | Square, heart, oval, circular, or custom contour cutout |

| Interior Coating | Greaseproof, moisture-resistant, or polyethylene-free barrier |

| Printing Resolution | Up to 1200 DPI for detailed imagery and text clarity |

| Tray Compatibility | Optional internal insert or tray for product stabilisation |

| Lamination Type | Matte, gloss, or anti-scratch BOPP lamination film |

| Edge Finishing | Machine-creased, sealed edges for precise alignment |

| Custom Artwork | Full-print capability for themes, patterns, or seasonal branding |

| Quantity Range | MOQ 100 units — scalable up to 100,000+ bulk runs |

| Temperature Tolerance | Stable under ambient bakery display and refrigeration conditions |

| Usage | Ideal for bakeries, dessert shops, event packaging, or takeaway gifting |

| Assembly | Delivered flat-packed or pre-folded for instant setup |

| Adhesive Type | Water-based, non-toxic glue for hygienic bonding |

| Structural Integrity | Supports light to medium-weight bakery products securely |

| Customisation Options | Logo, colour, size, finish, print, and window shape fully customisable |

| Inspection Standard | ISO 22000 & HACCP certified production for food-grade safety |

| Packaging Method | Bulk-packed or shrink-wrapped with moisture protection |

| Lead Time | Standard 7–10 working days post artwork approval |

| Optional Add-ons | Handles, ribbon ties, inserts, or branded sleeves available |

| Custom Offer | Tailored designs available for corporate gifting or seasonal bakery campaigns |

White Bakery Boxes With Window

Showcase your baked goods through white bakery boxes with windows that let customers see exactly what they’re buying before opening. These boxes work harder than solid packaging—the window creates impulse purchases by displaying your beautifully decorated cakes, cookies, cupcakes, and pastries while maintaining freshness and protection. The crisp white exterior provides a clean, professional backdrop that makes colorful frosting and decorations pop visually. Food-safe grease-resistant coating prevents oil stains from buttercream or glazes while the sturdy construction supports layered cakes and delicate pastries during transport. Windows are made from clear acetate that doesn’t fog or yellow, keeping your creations visible from bakery case to customer’s home.

Bakeries, cake decorators, and dessert caterers choose windowed boxes because they reduce the need for customers to open packaging before purchase—what they see is what they get. Available in multiple sizes and window configurations including full-top windows for large decorated cakes or small peek windows for cookie boxes and brownie packaging. The Product Boxes supplies bakery packaging solutions including cupcake inserts, cake boards, pastry bags, and donut boxes to complete your dessert presentation needs. Custom logo printing available to brand your bakery on every box. Wholesale quantities ensure you never run out during busy seasons.

Starting From: £0.50 Per Box

Available in Stock

Q: What type of window material is used in white bakery boxes with a viewing panel?

Q: How do window bakery boxes help improve product display?

Q: Which paperboard thickness provides stability for transporting baked goods?

Q: Can the window size or shape be customised?

Q: Are these white bakery boxes suitable for frosting-heavy or layered desserts?

Q: Can white bakery boxes with windows be printed or branded?

Q: Are these boxes grease-resistant for pastries or oily baked items?

Q: Can these boxes be shipped flat for easy storage?

Get an instant quote

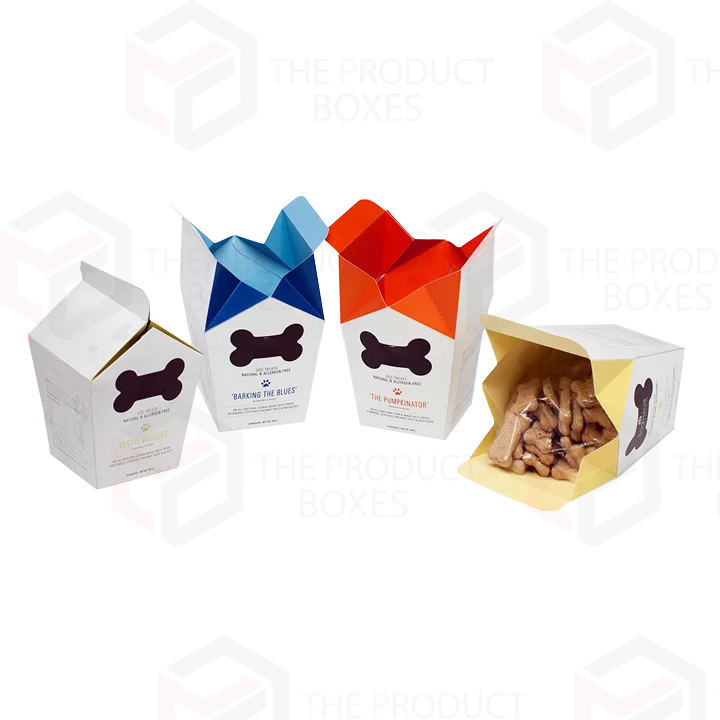

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.