Table of Contents

ToggleIn today’s global supply chain, product safety goes far beyond mere physical durability. For industries shipping temperature-sensitive items — from food and beverages to pharmaceuticals and cosmetics — maintaining the correct thermal conditions during transit is critical. Ordinary shipping cartons cannot protect products from heat, cold, or fluctuating temperatures, which can compromise quality, safety, and usability.

Temperature-controlled delivery boxes, designed to maintain specific temperature ranges, have evolved from niche solutions into essential tools for businesses worldwide. They help prevent spoilage, maintain product efficacy, and reduce financial and reputational risks, ensuring that perishable, sensitive, or high-value items reach customers in perfect condition.

This guide provides a complete overview of temperature-controlled packaging, including box types, insulation options, practical challenges, industry applications, and emerging trends.

What Are Temperature-Controlled Delivery Boxes?

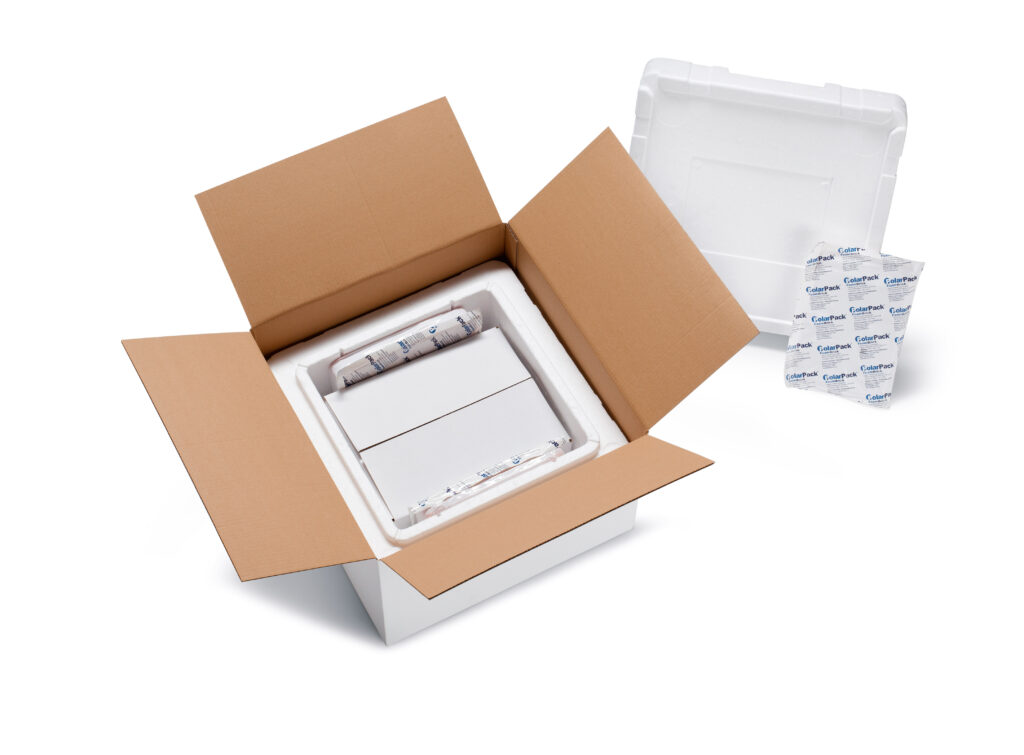

A temperature-controlled delivery box is a specialized packaging system engineered to keep its contents within a defined thermal range. Unlike standard cartons, these boxes act as micro-environments, protecting products from external temperature swings.

Key components of these boxes include:

- Insulating liners: Slow heat transfer and create a protective barrier.

- Cooling agents: Gel packs, dry ice, or phase change materials (PCMs) to maintain low temperatures.

- Active cooling systems: Battery-powered or electrically connected units for extended, controlled shipping durations.

These boxes are widely used in sectors such as:

- Food delivery: Frozen groceries, dairy, seafood, and ready-to-eat meals.

- Pharmaceuticals: Vaccines, insulin, blood samples, and biologic medicines.

- Beverages: Wines, craft beers, juices, and specialty teas.

- Specialty goods: Chocolates, fresh flowers, organic cosmetics, and other temperature-sensitive products.

By regulating the internal environment, these boxes ensure consistent product quality regardless of external conditions, from scorching heat to freezing cold.

Why Temperature Control Matters

Even minor temperature deviations can compromise product quality, shelf life, and safety. A shipment that arrives at the wrong temperature can result in financial losses, regulatory penalties, and loss of customer trust.

Primary Benefits:

- Product Safety: Maintains freshness, prevents bacterial growth, chemical breakdown, or structural changes.

- Customer Confidence: Items delivered in perfect condition foster loyalty and repeat purchases.

- Regulatory Compliance: Essential for pharmaceuticals and healthcare, where strict thermal standards apply.

- Cost Efficiency: Minimizes waste, refunds, and environmental impact.

- Brand Reputation: Prevents negative experiences that can quickly go viral in today’s social media landscape.

- Sustainability: Reduces waste by ensuring products reach consumers safely.

In short, temperature control protects not only products but the broader business ecosystem, from supplier relationships to consumer satisfaction.

Types of Temperature-Controlled Delivery Boxes

Understanding the different types of boxes helps businesses choose the best solution for their specific needs.

1. Passive Cooling Boxes

Passive boxes rely entirely on insulation and cooling packs without powered components.

Key Features:

- Lightweight, cost-effective, and widely used

- Maintain temperature stability for 12–48 hours

- Ideal for frozen meal kits, dairy subscriptions, or local farm-to-table deliveries

Advantages: Affordable, simple, scalable for moderate volumes.

Limitations: Limited duration and performance depend on insulation and cooling pack quality.

2. Active Cooling Boxes

Active cooling boxes use batteries or electricity to maintain precise temperatures over extended periods.

Key Features:

- Stable temperatures for 48+ hours

- Integrated monitoring systems with digital displays and alarms

- Often used for vaccines, organ transport, or high-value biotech shipments

Advantages: Reliable for critical, temperature-sensitive shipments.

Limitations: Higher cost and requires maintenance and power management.

3. Insulated Cardboard Boxes

Eco-conscious brands often prefer insulated cardboard boxes lined with foil, foam, or plant-based materials.

Key Features:

- Lightweight and recyclable

- Suitable for overnight or next-day delivery (24–36 hours)

- Popular in meal kits, premium chocolates, and organic products

Advantages: Combines insulation with sustainability and aesthetic appeal.

Limitations: Less durable than plastic or active cooling boxes.

4. Rigid Plastic Thermal Boxes

Reusable plastic boxes provide consistent performance over multiple shipping cycles.

Key Features:

- Durable polymer construction

- Thermal protection for 48–96 hours

- Ideal for catering, pharma logistics, or repeated delivery routes

Advantages: Economical over repeated use; stable protection.

Limitations: Higher upfront cost and heavier than cardboard.

5. Expanded Polystyrene (EPS) Boxes

EPS boxes are classic insulated containers, widely used in seafood, vaccines, and laboratory shipments.

Key Features:

- Maintain temperature for 24–48 hours

- Lightweight and cost-effective

- Common in industries prioritizing performance over environmental concerns

Advantages: Reliable insulation; widely available

Limitations: Non-biodegradable; growing environmental scrutiny

Table 1: Comparison of Box Types

| Box Type | Insulation Duration | Cost | Reusability | Ideal Use Case |

|---|---|---|---|---|

| Passive Cooling | 12–48 hrs | Low | Single-use | Frozen meals, groceries |

| Active Cooling | 48+ hrs | High | Reusable | Vaccines, biotech samples |

| Insulated Cardboard | 24–36 hrs | Medium | Single-use | Meal kits, eco-friendly deliveries |

| Rigid Plastic | 48–96 hrs | High | Reusable | Pharma, catering |

| EPS | 24–48 hrs | Medium | Limited | Seafood, medical samples |

Insulation Materials

The effectiveness of a temperature-controlled box often depends on the liner used.

Common Liner Types:

- Foil Liners: Reflect heat, excellent for cold retention; recycling can be difficult.

- Foam Liners (PU/EPS): Excellent insulation for frozen goods and vaccines; not biodegradable.

- Plant-Based Liners: Cornstarch, hemp, mushroom mycelium; sustainable but slightly less effective in extreme conditions.

- Air-Cell (Bubble) Liners: Affordable and lightweight; suitable for short-distance shipments.

Table 2: Liner Performance

| Liner Type | Temperature Performance | Sustainability | Cost | Best Use Case |

|---|---|---|---|---|

| Foil | High | Low | Low | Food & pharma |

| Foam | Very High | Low | Medium | Frozen goods, vaccines |

| Plant-Based | Medium | High | Medium | Eco-focused brands |

| Air-Cell | Low–Medium | Medium | Low | Short deliveries |

Challenges in Temperature-Controlled Shipping

- Temperature Fluctuations: Delays or exposure to extreme conditions can affect product safety.

Solution: Choose boxes with buffer capacity and plan for extra thermal protection. - Condensation: Moisture can damage labels or packaging integrity.

Solution: Use moisture-resistant liners and absorbent packets. - Cost Pressures: Active cooling can be expensive for small businesses.

Solution: Insulated cardboard boxes with gel packs offer reliable, affordable protection. - Environmental Concerns: EPS and foam contribute to landfill waste.

Solution: Transition to recyclable or biodegradable liners; encourage returns for reuse. - Size and Weight: Additional insulation increases shipping costs.

Solution: Optimize box design and insulation thickness; consider tiered protection based on shipment sensitivity.

Industry Applications

- Meal Kit Companies: HelloFresh, Blue Apron, Home Chef rely on insulated boxes with gel packs for safe delivery of fresh ingredients.

- Pharmaceutical & Biotech: Pfizer, Moderna, and organ transport networks require precise temperature management.

- Beverages: Wineries, craft breweries, and cold-pressed juice producers use thermal boxes to preserve flavor and quality.

- Cosmetics & Skincare: Lush, The Body Shop, and organic brands maintain product integrity during shipping.

Real-World Case Study

Meal kit companies like HelloFresh have revolutionized cold chain logistics by using insulated cardboard boxes with gel packs:

- Maintain 24–36 hours of temperature stability for overnight or next-day delivery

- Lightweight and cost-effective compared to rigid plastic

- Recyclable and aligned with sustainability goals

- Easy to scale for millions of shipments globally

This demonstrates that eco-friendly packaging can also provide reliable thermal protection without compromising efficiency.

Future Trends in Temperature-Controlled Packaging

- Smart Sensors: IoT-enabled temperature monitors track conditions in real time, providing accountability and data for logistics optimization.

- Reusable Systems: Multi-use boxes reduce waste and lower long-term costs; companies like LimeLoop and RePack are pioneering circular logistics.

- Eco-Friendly Liners: Biodegradable foams, mushroom mycelium insulation, and fiber-based alternatives reduce environmental impact.

- Hybrid Cooling Models: Passive insulation combined with small active components provides extended protection without full energy consumption.

- Predictive Logistics Integration: AI predicts weather, routes, and delays to dynamically choose optimal packaging solutions.

- Nano-Insulation Materials: Aerogels and vacuum panels reduce bulk while maintaining superior insulation.

Global logistics leaders such as DHL, FedEx, UPS, and Amazon Fresh are actively adopting these innovations to meet growing consumer expectations and regulatory demands.

Conclusion: Choosing the Right Solution

Selecting the ideal temperature-controlled box depends on several factors: product type, shipping duration, volume, budget, and sustainability priorities.

- Cost-conscious brands: Insulated cardboard boxes with gel packs provide reliable, affordable protection.

- High-value pharmaceuticals: Active cooling or rigid reusable containers ensure regulatory compliance and safety.

- Eco-conscious companies: Plant-based or recyclable liners support environmental messaging while maintaining performance.

- Predictable routes: Reusable rigid boxes lower costs over repeated shipments.

- Seasonal shippers: Single-use passive solutions offer flexibility without long-term storage commitments.

Temperature-controlled packaging is more than a logistics necessity — it is a strategic investment in product quality, customer satisfaction, regulatory compliance, and overall business success. As supply chains grow more complex, companies that master thermal logistics gain a competitive advantage, ensuring products and customers are protected worldwide.