| Type | Specification |

|---|---|

| Product Name | 10 oz Candle Boxes |

| Material Options | Premium SBS Paperboard, Rigid Chipboard, Corrugated Cardboard, Kraft Paper |

| Coating/Finish | Gloss, Matte, Soft-Touch, AQ Coating, UV Spot, Varnish, Lamination |

| Printing Type | Offset, Digital, Flexographic, Screen Printing |

| Printing Colours | CMYK, PMS (Pantone Matching System) |

| Custom Sizes | Tailored to Fit 10 oz Candle Jars (Typical: 3.5 x 3.5 x 4 inches) or Fully Customisable |

| Box Style | Auto-Lock Bottom, Reverse Tuck End, Two-Piece Rigid, Sleeve Style, Window Cut-Out |

| Insert Options | Die-Cut Cardboard Insert, Foam Insert, Molded Pulp Insert, EVA Foam |

| Logo Application | Embossing, Debossing, Foil Stamping (Gold/Silver/Holographic), UV Spot |

| Colour Options | Full-Colour Printing, Metallic Inks, Natural Kraft, Blackout or Pastel Shades |

| MOQ | Low Minimums – Custom Quantity as per Requirement |

| Customisation | Full Custom Box Design, Structural Engineering, Mockup Support |

| Eco-Friendly Options | Recyclable, Biodegradable, FSC® Certified Stock, Soy-Based Inks |

| Usage | Luxury Candle Packaging, Gift Packaging, Subscription Boxes, Retail Display |

| Closure Types | Magnetic Closure, Tuck-In Flaps, Slide-In Sleeves, Ribbon Closure |

| Production Lead Time | 7–12 Business Days (Rush Orders Available) |

| Shipping Options | Flat Packed or Fully Assembled; Global Delivery Support |

10 oz Candle Boxes

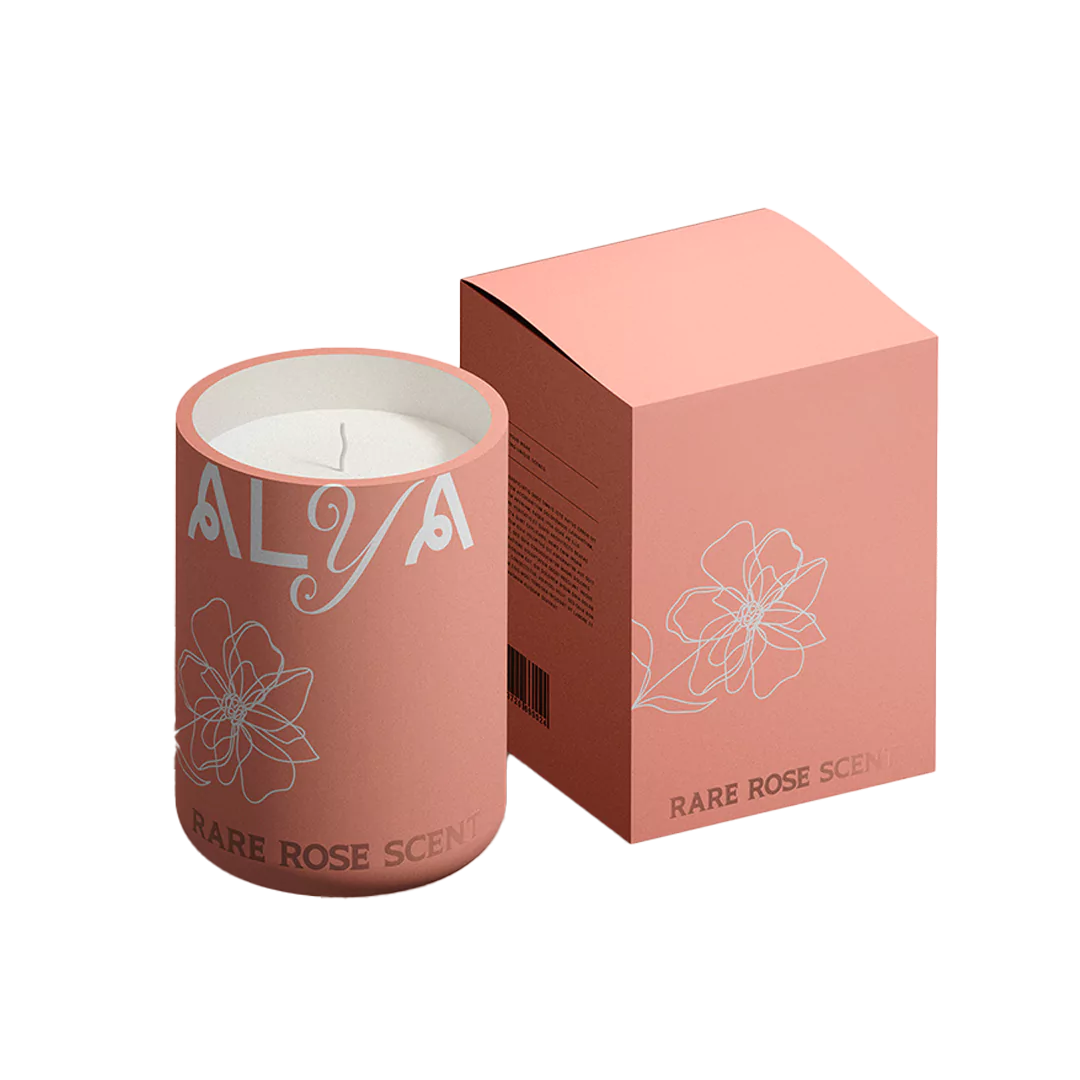

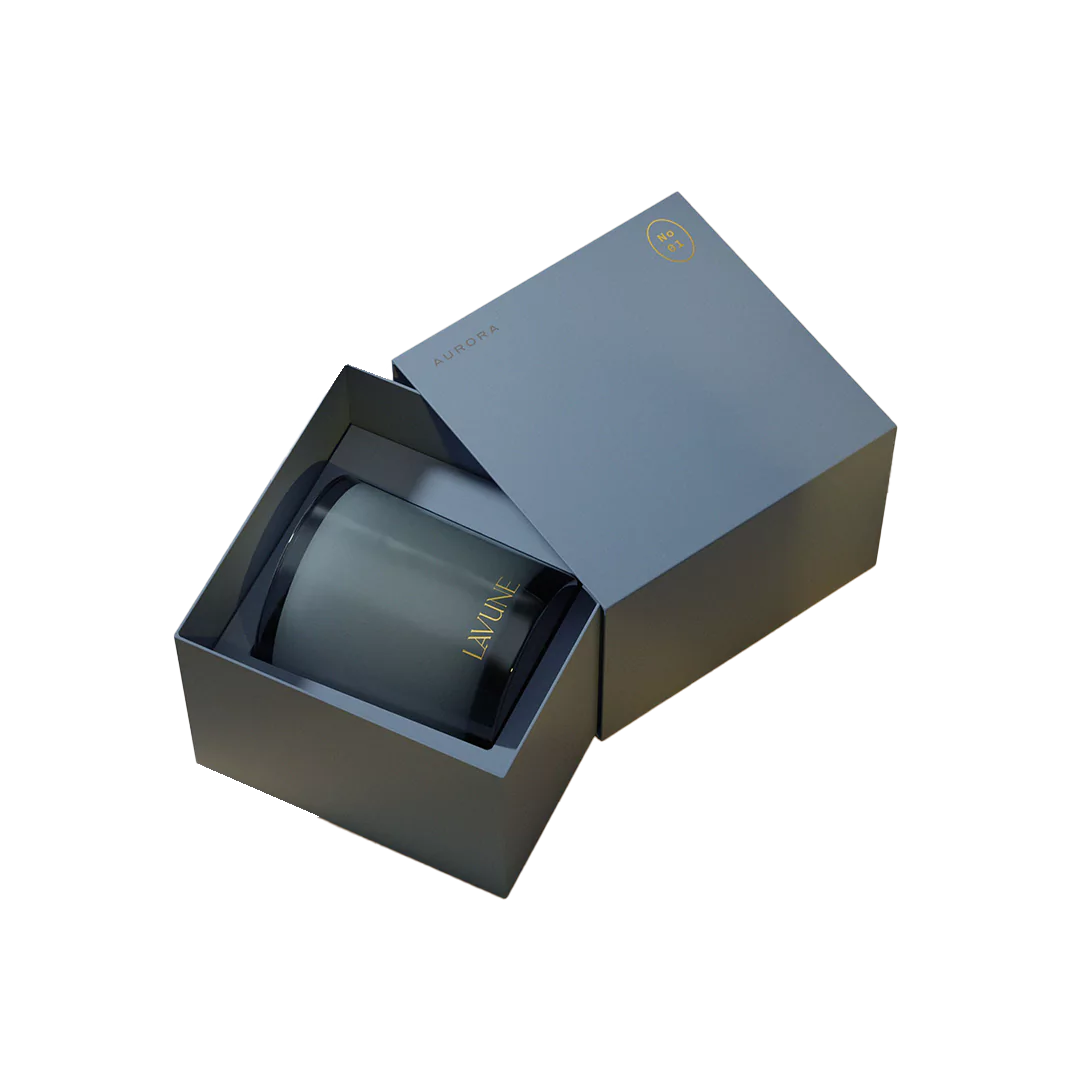

Boxes made for 10 oz candles help keep the candle safe and add a nice touch to your shop. At The Product Boxes UK, we provide custom packaging for 10 oz candle boxes, making sure they fit well and are safe during different stages of your business. These boxes are constructed from sturdy corrugated cardboard, rigid board or kraft, you can add your logo and colours, as well as extra inserts to keep your products safe.

Moreover, we allow our customers to present your candles in either a straight kraft style or with a beautiful, printed design. Get your candles safe and secure all the time. So, don’t wait and contact us for custom jar candle packaging boxes for larger and smaller brands. Have thoughtful gift ideas and displays on the shelves with TPB.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make 10 oz Candle Boxes?

Q. Are these candle boxes available in custom sizes and styles?

Q. Can I get my logo printed on the boxes?

Q. Do you provide insert options for candle protection?

Q. Are these boxes suitable for gift or retail use?

Q. Can I order these boxes in eco-friendly materials?

Q. What is the minimum order quantity (MOQ)?

Q. What finishes are available for the candle boxes?

Q. Can I add a window to the candle box design?

Q. How long does production and shipping usually take?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.