| Type | Specification |

|---|---|

| Cup Capacity | 12 oz Standard Volume (350–360 ml), Ideal for Hot & Cold Beverages |

| Material Grade | Food-Grade Cupstock Board, 300–350 GSM, High-Rigidity Structure |

| Wall Type | Single Wall / Double Wall / Ripple Wall Heat-Proof Construction |

| Printing Method | CMYK Offset, Pantone Precision Print, Short-Run Digital Print Available |

| Logo & Artwork | Full-Wrap Branding, High-Resolution Logo Print, Spot UV, Fine-Line Detail |

| Colour Options | Full Colour, Pantone Solids, Kraft Brown Base, Custom Gradient Finishes |

| Coating Type | Single PE / Double PE Lining, PLA Compostable Lining for Eco Variant |

| Heat Tolerance | Maintains Strength up to 95°C; Anti-Scald Double Wall Option |

| Lid Compatibility | Standard 90mm Rim Size; Fits Dome & Flat Lids (PP/PS) |

| Rim Style | Rolled Rim for Leak Control & Secure Lid Grip |

| Eco Options | Biodegradable PLA Cups, Recyclable Cupstock, Water-Based Inks |

| Custom Features | Embossing, Foiling, QR Codes, Matte Soft-Touch Lamination |

| Use Applications | Coffee, Lattes, Cappuccino, Tea, Juices, Corporate Events, Café Branding |

| Packaging Quantity | 50 Cups per Sleeve; 1000–1200 Cups per Carton (Custom Batch Options) |

| Compliance | FDA Food-Contact Approved, BPA-Free, EU 1935/2004 Standard |

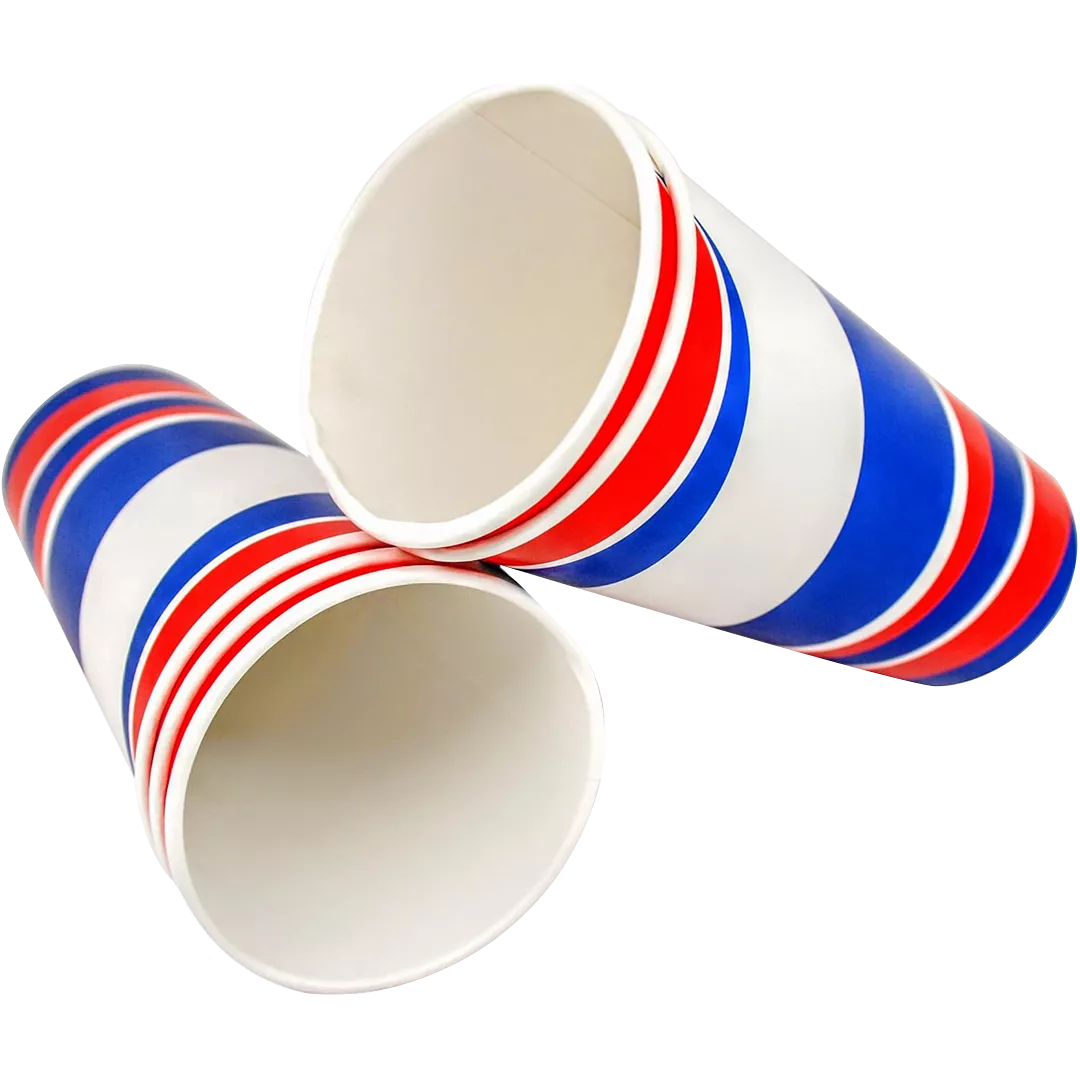

12 ounce Paper Cups

The workhorse size for coffee shops and beverage service operations. These 12 ounce paper cups handle medium coffees, soft drinks, smoothies, and iced beverages without being too large or wastefully small for most customer orders. This capacity matches what most customers expect when ordering a regular-sized drink, making it the highest-turnover inventory item for cafés and quick-service restaurants. The cups work equally well for hot and cold service with appropriate lining options. Single-wall versions keep costs low for cold beverages while double-wall construction provides heat insulation for hot drinks without requiring separate sleeves.

Stock them plain in white or kraft for universal use across your menu, or order custom printed versions with your branding. The 12 oz size provides excellent surface area for logo placement and promotional messaging that customers carry through streets and offices. Compatible with standard dome lids for cold drinks and flat sip lids for hot beverages. The Product Boxes supplies personalised paper cups in bulk wholesale quantities with volume pricing that makes sense for businesses serving hundreds daily. Available with poly coating for moisture resistance or PLA lining for compostable options. The tapered design allows efficient stacking and the reinforced rim prevents collapsing when filled. Order plain stock for immediate shipping or commission printed designs that enhance your brand visibility with every sale.

Starting From: £0.50 Per Box

Available in Stock

Q: What materials are used for 12-ounce paper cups?

Q: Are 12-ounce paper cups suitable for hot drinks like coffee or tea?

Q: Can 12-ounce paper cups be customised with logos or designs?

Q: How does cup design affect lid compatibility?

Q: Are eco-friendly 12 oz paper cups available?

Q: What is the standard size and dimension of 12-ounce cups?

Q: How should 12 oz paper cups be packaged for bulk shipping?

Q: Can 12-ounce paper cups maintain beverage temperature?

Q: Are 12-ounce cups stackable for storage efficiency?

Q: What finishing options improve the appearance and durability of 12 oz cups?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.