| Type | Specification |

|---|---|

| Box Dimensions | 3.5″ x 3.5″ x 1.5″ (customizable height/depth) |

| Material Options | Rigid chipboard, kraft board, textured cardboard, SBS paperboard |

| Printing Method | Offset, digital, and screen printing available for high-resolution branding |

| Color Model | CMYK & Pantone (PMS) color options supported |

| Finish Options | Gloss/matte lamination, soft-touch coating, linen wrap, UV spot, foil stamping |

| Logo Application | Custom logos via embossing, debossing, foil stamping, or full-color print |

| Insert Styles | Foam, velvet, cardboard inserts—die-cut to fit rings, earrings, pendants |

| Closure Style | Magnetic flap, two-piece lid-base, slide drawer, or ribbon tie options |

| Surface Texture | Plain, linen, leatherette, suede, or metallic finish options |

| MOQ | Starts from 100 boxes (bulk and wholesale discounts available) |

| Use Cases | Jewelry sets, gift packaging, product display, luxury branding |

| Custom Features | Die-cut windows, QR codes, product care info, padding or mirror inserts |

| Eco-Friendly Options | Recyclable board, soy-based ink, biodegradable inserts on request |

| Production Time | 7–12 business days (rush orders available) |

| Packing Method | Flat packed or pre-assembled, based on box type and order volume |

3.5 x 3.5 Jewelry Boxes

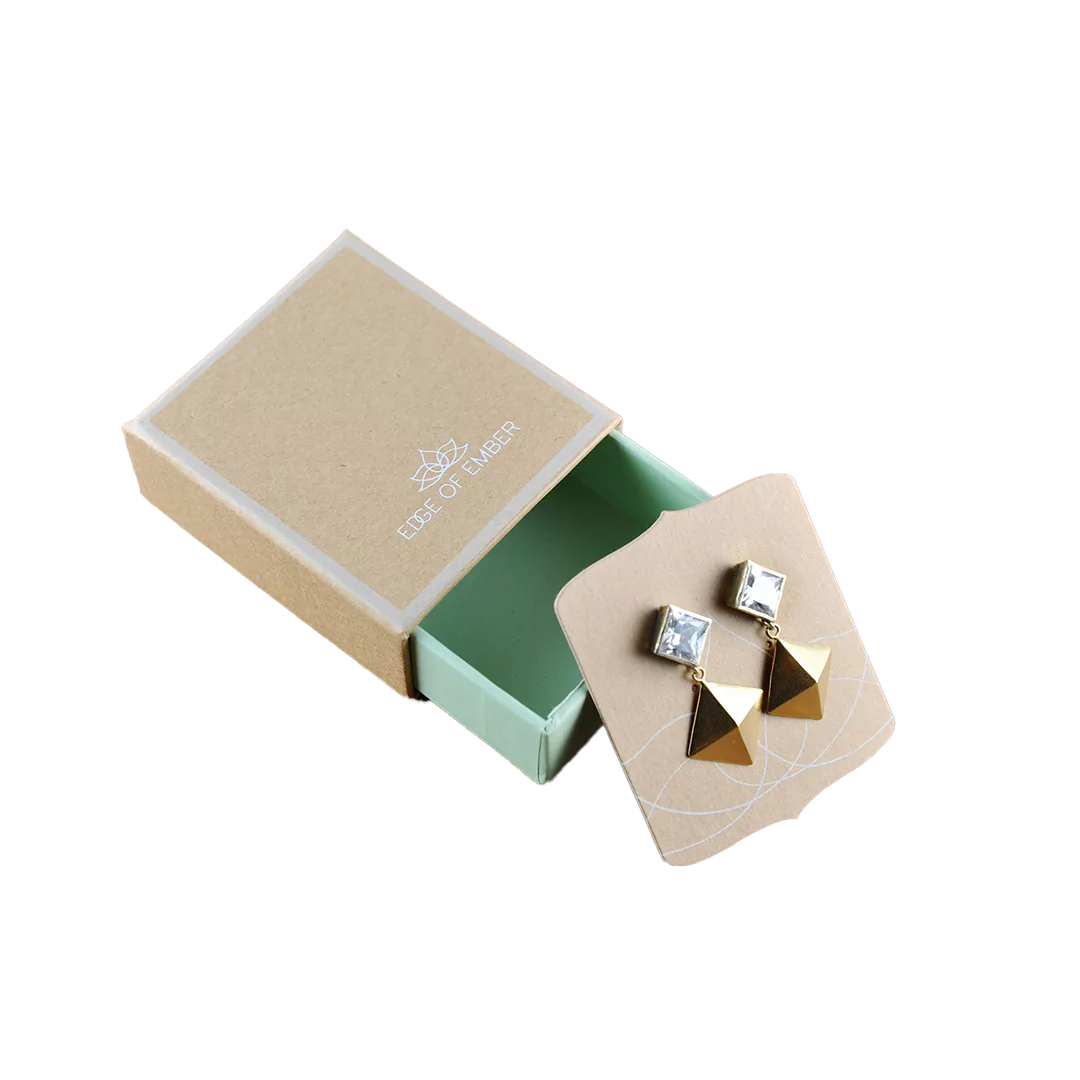

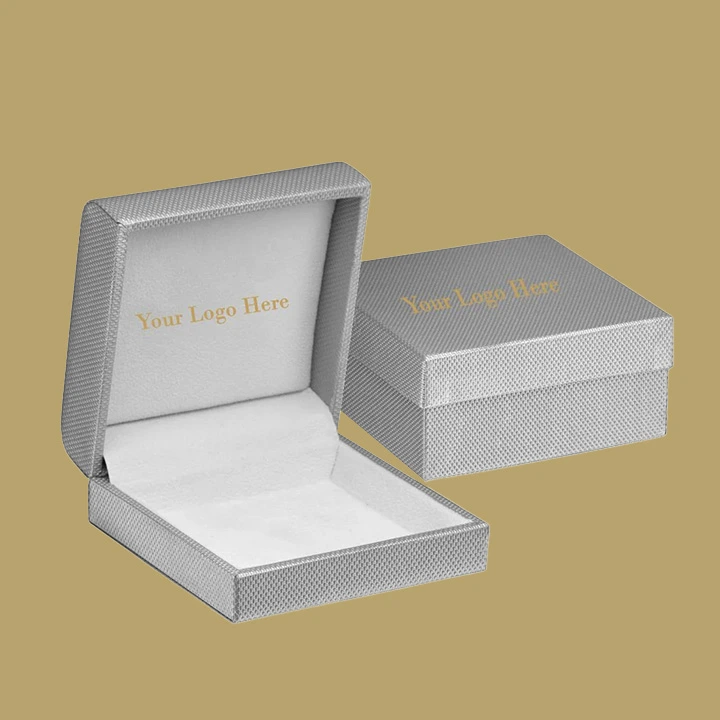

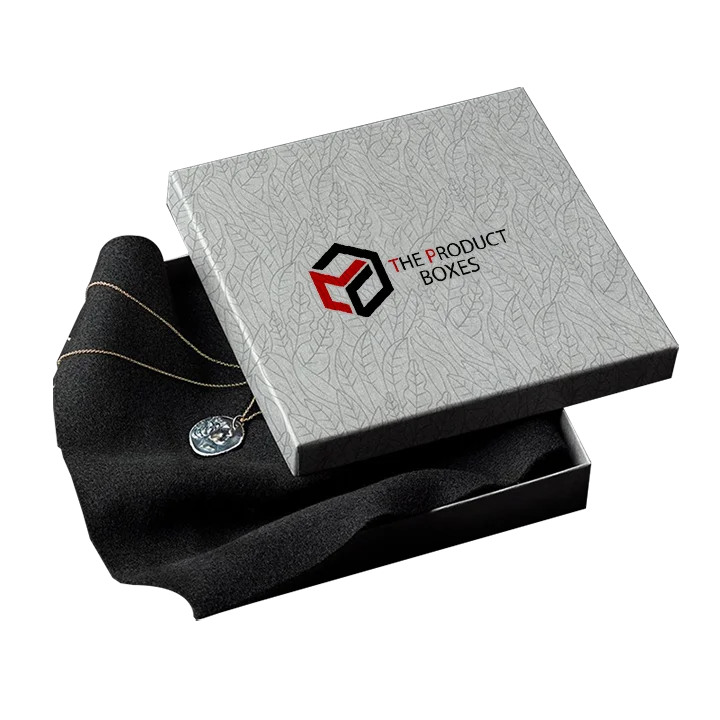

3.5 x 3.5 jewelry boxes is the ideal size for packaging rings, bangels, earrings, brooches and small pendants. These boxes are made to be elegant and strong so they can protect as well as show your jewellery items. Our personalised boxes at The Product Boxes can be customised and are made from a range of materials such as rigid materials, kraft and textured ones.

Give your jewellery a special look by adding custom printing, foil stamping, UV printing, inserts and branded stickers. Best used for selling in boutiques or for special events, these boxes let you enjoy an impressive unboxing and secure your treasures. So, what’re you waiting for? Contact TPB for custom jewellery boxes wholesale with fast delivery and 24/7 customer support all over the UK.

Starting From: £1 Per Box

Available in Stock

Q. What materials are used to make 3.5 x 3.5 Jewelry Boxes?

Q. Are these boxes suitable for shipping delicate jewelry items?

Q. Can I customize the design, color, or logo on these jewelry boxes?

Q. Do these boxes come with inserts for jewelry display?

Q. Are these boxes eco-friendly?

Q. What type of closure options are available for 3.5 x 3.5 jewelry boxes?

Q. What is the minimum order quantity for custom jewelry boxes?

Q. Can these boxes be used for gifting or retail display?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.