| Type | Specification |

|---|---|

| Material | Kraft paperboard, SBS board, corrugated kraft, or recycled chipboard with food-grade coatings |

| Printing Options | Full-colour CMYK, Pantone (PMS), screen printing, and flexographic printing |

| Coating | Gloss lamination, matte lamination, aqueous coating, or food-safe grease-resistant barrier |

| Closure Styles | Clamshell, tuck-top, tab-lock, die-cut interlock, or hinged-lid structures |

| Logo Application | Custom logo with embossing, debossing, foil stamping (gold/silver), or spot UV |

| Custom Sizes | Available in standard single (4×4 in), large (5×5 in), and custom dimensions on request |

| Colours | Natural kraft brown, black kraft, or fully customised prints with brand colours |

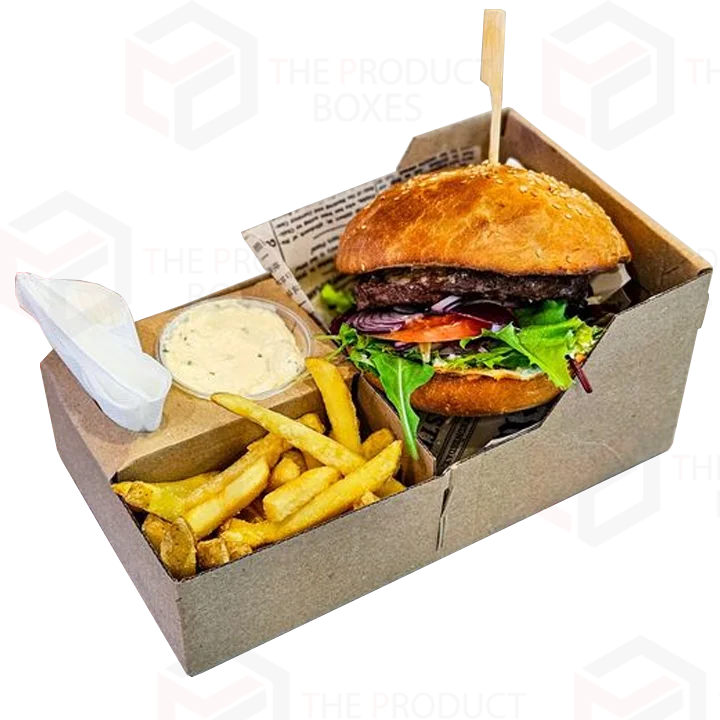

| Box Styles | American-style burger box with integrated ventilation and stackable design |

| Window Option | Optional PET/PLA transparent window or die-cut open-view slot |

| Finish Types | Soft-touch, anti-scuff, satin varnish, or textured uncoated kraft |

| Printing Surface | Interior and exterior printable surfaces available |

| Eco-Friendly | 100% recyclable, biodegradable, FSC-certified materials used |

| MOQ | Starts from 100 boxes — scalable for large volume production |

| Packaging | Flat-packed or pre-glued options; shipped in corrugated outer cartons |

| Lead Time | Standard: 7–12 business days; Rush orders available |

| Use Case | Ideal for burgers, sliders, sandwiches, and takeaway meal packaging |

American Burger Boxes

American burger boxes provide the suitable solution for your bold-flavored large burgers. These burger boxes are particularly designed to serve food outlets that operate as fast-food chains and restaurants. The Product Boxes UK offer custom printed burger boxes from durable cardboard which serves as efficient packaging for both takeout and dining arrangements. Get access to whatever you need like Americana design, retro diner-themed or brand-identity-specific packaging. Our full customisation service;provide logo printing; patriotic colour selection; eye-catching graphics; and branded slogans.

These burgers serve customers with different food volumes starting from the individual to the combination of multiple items because as we create variable package structures that support food safety and presentation quality. Moreover, our customers can easily achieve style and pricing efficiency with our bulk American burger box solutions. Enjoy quick manufacturing with brand-centric designs at The Product Boxes.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make American Burger Boxes?

Q. Are American Burger Boxes suitable for greasy and hot burgers?

Q. Can I customise American Burger Boxes with my brand logo?

Q. Do American Burger Boxes come in different sizes?

Q. Are American Burger Boxes eco-friendly?

Q. What closure styles are available in American Burger Boxes?

Q. What type of finishes can I apply to my American Burger Boxes?

Q. Can I print inside the American Burger Boxes?

Q. Do you provide samples before bulk ordering?

Q. What is the minimum order for custom American Burger Boxes?

Q. What is the typical turnaround time for these boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.