| Type | Specification |

|---|---|

| Material | Corrugated Cardboard, Kraft Paper, Rigid Board, Duplex Board |

| Printing Options | CMYK, PMS, Digital, Offset, Screen Printing |

| Finishing | Gloss, Matte, Soft-Touch, Spot UV, Embossing, Debossing, Foil Stamping |

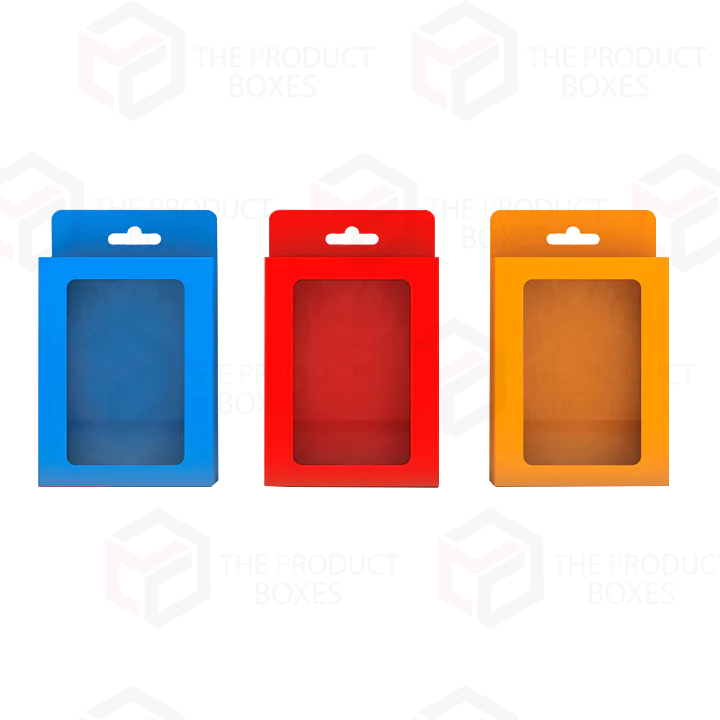

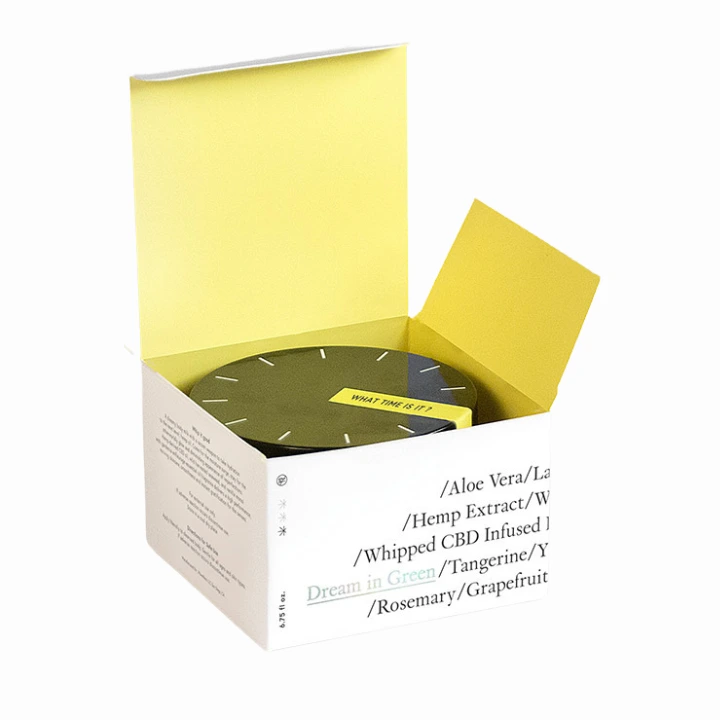

| Customization | Custom Shapes, Sizes, Cutouts, Inserts, and Window Patching |

| Handles | Die-Cut Handles, Rope Handles, Ribbon Handles, Reinforced Grip Handles |

| Eco-Friendly | 100% Recyclable, Biodegradable, FSC-Certified Materials |

| Logo & Branding | Custom Logo Printing with Embossing, Debossing, Foil, and UV Coating |

| Sizes | Custom Sizes for 1, 2, 4, 6, and 12-Bottle Packaging |

| Thickness | 12pt, 14pt, 16pt, 18pt, 24pt (Custom Available) |

| Structural Design | Auto-Lock Bottom, Tuck-Top, Carry Handle, Divider Inserts |

| Quantity | Available in Low & Bulk Order Quantities |

| Usage | Beverages, Alcohol, Craft Beer, Soft Drinks, Specialty Drinks |

| Production Time | 7-14 Business Days (Rush Order Available) |

| Shipping | Flat-Packed or Pre-Assembled Shipping Options |

Beverage Product Boxes

Make your beverages stand out in special beverage product boxes designed to help with branding, protection and for durability. These boxes provide safe transportation for juices, soft drinks, energy drinks, soda drinks or any other beverage. Made from premium quality cardboard or corrugated materials, these boxes are also stable and moisture resistant, which helps improve their professional look for retail displays. The product boxes proudly offer custom beverage packaging boxes for your brand.

You also have the option to select the size and the shape you prefer with a coat of gloss or matte finish, embossing, foil stamp, die cut window, or even get a handle for direct easy carrying. If you need single bottle, multi pack or promotional boxes, we guarantee you’ll be satisfied with our expertly crafted boxes. Without compromising on quality, we offer wholesale custom product boxes for bulk orders as an affordable solution. So, don’t wait and enhance your brand with packaging that combines function with style. Order your custom beverage boxes that are sure to make your products stand out.

Starting From: £1 Per Box

Available in Stock

Q. What materials are used to make Beverage Product Boxes?

Q. Can I customize the size and design of Beverage Product Boxes?

Q. What printing options are available for Beverage Product Boxes?

Q. Are Beverage Product Boxes eco-friendly?

Q. Can I add my company logo and branding to Beverage Product Boxes?

Q. What bottle sizes can fit in Beverage Product Boxes?

Q. What closure and handle options are available for Beverage Product Boxes?

Q. Do you offer bulk ordering for Beverage Product Boxes?

Q. Can I get a sample of Beverage Product Boxes before bulk production?

Q. What industries commonly use Beverage Product Boxes?

Q. What is the production time for Beverage Product Boxes?

Q. Do you offer flat-packed or pre-assembled shipping for Beverage Product Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.