| Type | Specification |

|---|---|

| Material | Acid-Free Premium Tissue (100% Virgin Wood Pulp) |

| Finish | Printed Surface with Black & White Stripes – Matte or Semi-Gloss |

| Grammage | 17 GSM, 18 GSM, 20 GSM (Custom GSM Available) |

| Color Pattern | Alternating High-Contrast Black and White Vertical Stripes |

| Stripe Width | Standard 1″ Stripes (Custom Widths on Request) |

| Print Method | Rotogravure or Flexographic Precision Printing |

| Sheet Size | 15″ x 20″, 17″ x 23″, 20″ x 30″, 24″ x 36″ (Fully Custom Sizes Offered) |

| Custom Sizing | Yes – Width & Length Fully Customizable Per Product Requirement |

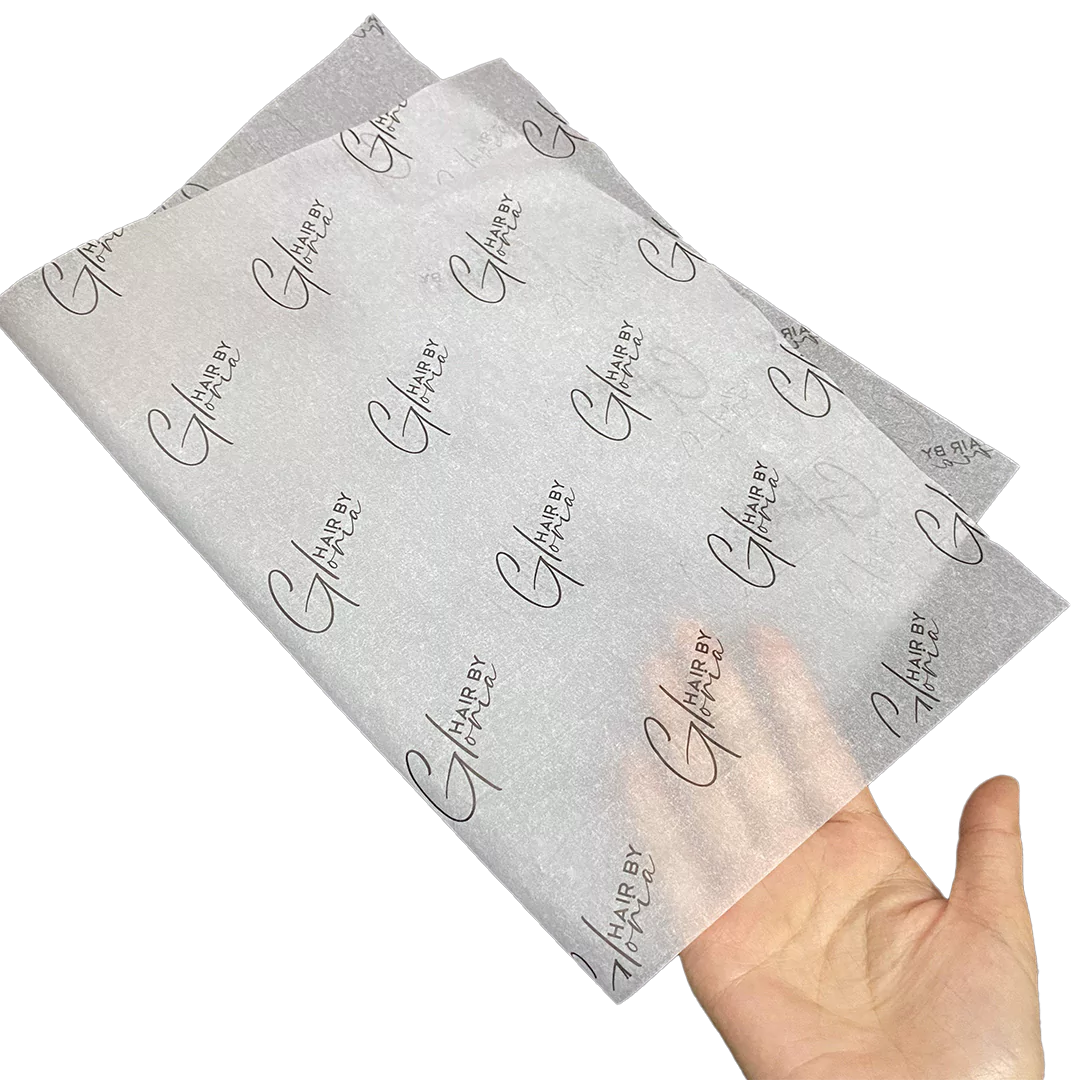

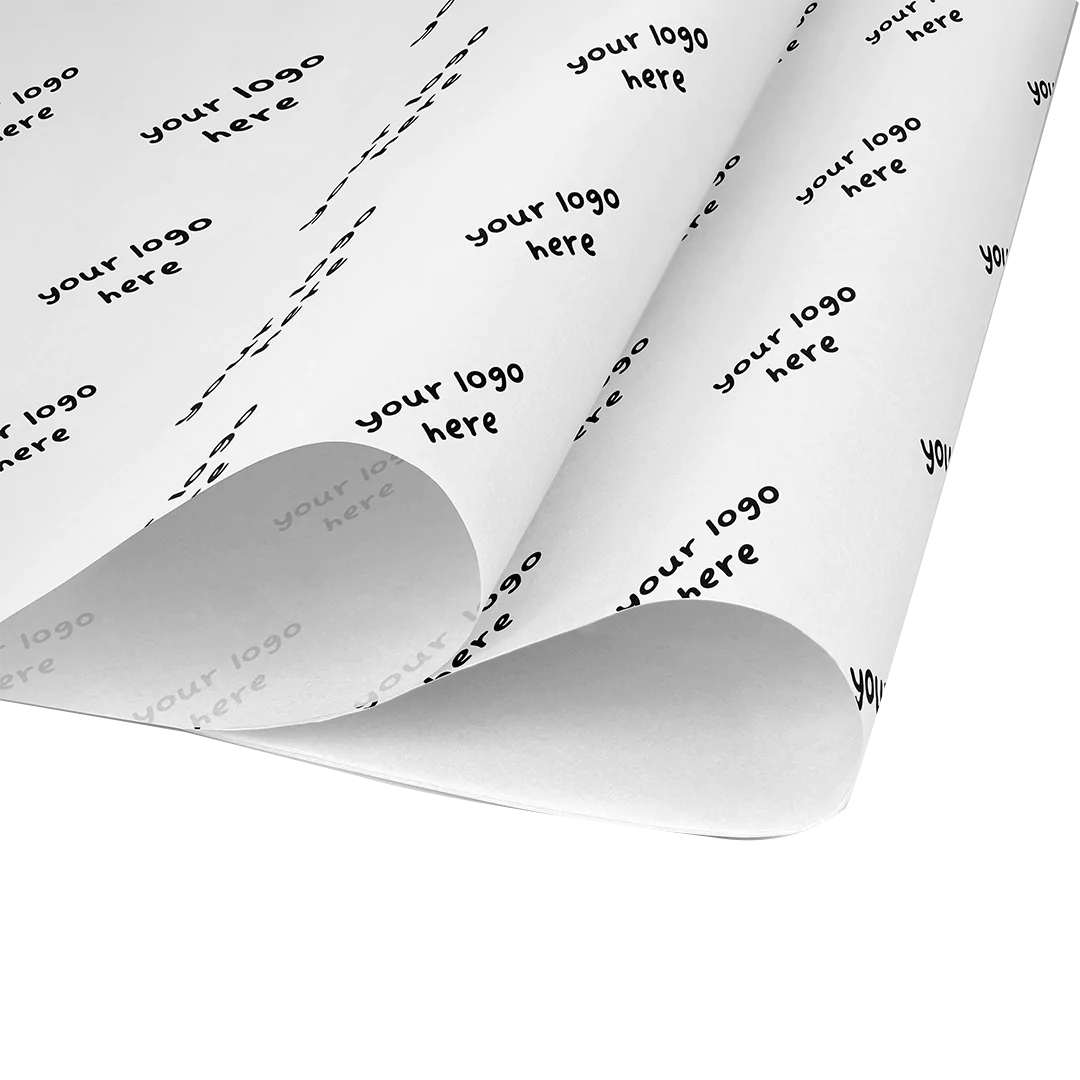

| Logo Printing | Optional – Custom Logo Overlay or Watermark on Stripe Pattern |

| Ink Type | Soy-Based Non-Toxic Ink / Fade-Resistant High-Density Pigment |

| Opacity | Semi-Transparent or Opaque Base (User-Selectable) |

| Recyclability | 100% Recyclable and Compostable |

| Use Case | Luxury Retail Packaging, Gift Wrap, Fashion Accessories, Cosmetics |

| Folding Options | Flat Packed, Roll Packed, or Pre-Folded (Based on Order) |

| Packaging Method | Wrapped in Kraft Reels or Shrink Film – Optional Branding on Wrap |

| Quantity Range | Starting from 500 Sheets – Bulk Production Available Up to 500,000+ |

| Perforation | Optional Perforated Edge for Easy Tearing |

| MOQ for Custom Print | As Low As 1,000 Sheets with Personalized Brand Overlay |

| Scent Option | Optional Light Fragrance Infusion (Lavender, Vanilla, Custom) |

| Compliance | EN71, FSC Certified, pH Neutral – Safe for Garments & Jewelry |

| Sample Service | Free Unprinted Sample / Printed Sample Available Upon Request |

Black and White Striped Tissue Paper

Make your packaging stand out with the bold, eye-catching pattern of Black and White Striped Tissue Paper. These crisp, alternating lines aren’t just stylish — they create an instant visual rhythm that elevates any retail or gift presentation. Ideal for fashion accessories, clothing, and subscription boxes, the striped design brings an intentional, boutique feel to your unboxing without the need for extra decoration.

The paper is acid-free, smooth, and lightweight, yet durable enough to wrap items securely or add layering inside boxes. Each sheet features clean-cut black and white stripes that work beautifully with branded stickers, ribbons, or custom tissue seals. Whether you’re curating a classic monochrome theme or aiming for modern contrast, stripes deliver impact with elegance. Supplied in flat stacks for easy handling, our striped tissue paper is available in bulk with fast turnaround.

Starting From: £0.50 Per Box

Available in Stock

Q. Is the black and white striped tissue paper colorfast or will it bleed on products?

Q. What GSM weight is ideal for striped tissue paper used in packaging?

Q. Can black and white striped tissue paper be customized with logos?

Q. Is this striped tissue paper acid-free and safe for delicate items?

Q. What are the common sheet sizes available for black and white striped tissue?

Q. Are both vertical and horizontal stripe patterns available?

Q. Is this tissue paper recyclable and eco-friendly?

Q. How is the stripe print applied—will it smudge under pressure?

Q. Does the striped pattern show through translucent packaging?

Q. Can the black and white stripe pattern be printed in matte or gloss finish?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.