| Type | Specification |

|---|---|

| Material | Food-Grade Kraft or Bleached Paper – FSC Certified |

| GSM Range | Custom 24–45 GSM Options (Standard: 28, 30, 35 GSM) |

| Print Method | Flexographic or Offset, Food-Safe Water-Based Ink |

| Brand Logo Print | Edge-to-Edge Pattern, Repeated Logo, or Center Stamp |

| Colour Options | Single Colour, Multi-Colour, or CMYK + PMS Custom |

| Ink Safety | FDA-Approved, Non-Toxic, Grease-Resistant Ink |

| Greaseproof Level | Kit 3–9 Rating – Custom Barrier Strength Available |

| Coating | Uncoated, Wax-Coated, or PE Barrier for Moisture Control |

| Finish | Natural Kraft Texture, Matte or Light Gloss Available |

| Sheet Sizes | Custom Cut (e.g. 10×10″, 12×12″, A4, 15×15″) |

| Roll Options | Custom Widths in Continuous Branded Rolls |

| Applications | Wraps, Tray Liners, Basket Liners, Sandwich Wraps |

| Freezer Safe | Yes – Available with Wax or PE Coated Paper |

| Microwave Compatibility | Yes – Ink and Stock Tolerant to Heat Exposure |

| MOQ | From 1,000 Custom Printed Sheets or 1 Roll |

| Biodegradability | 100% Compostable and Recyclable Kraft Options |

| Certifications | FDA, BRCGS, ISO 22000 for Direct Food Contact |

| Custom Shapes | Die-Cut Sheets for Trays, Boxes, or Promotional Use |

| Sample Option | Free Blank or Branded Sample Sheet Available |

| Bulk Packing | Flat Packed in Reams or Rolls with Moisture Barrier Wrap |

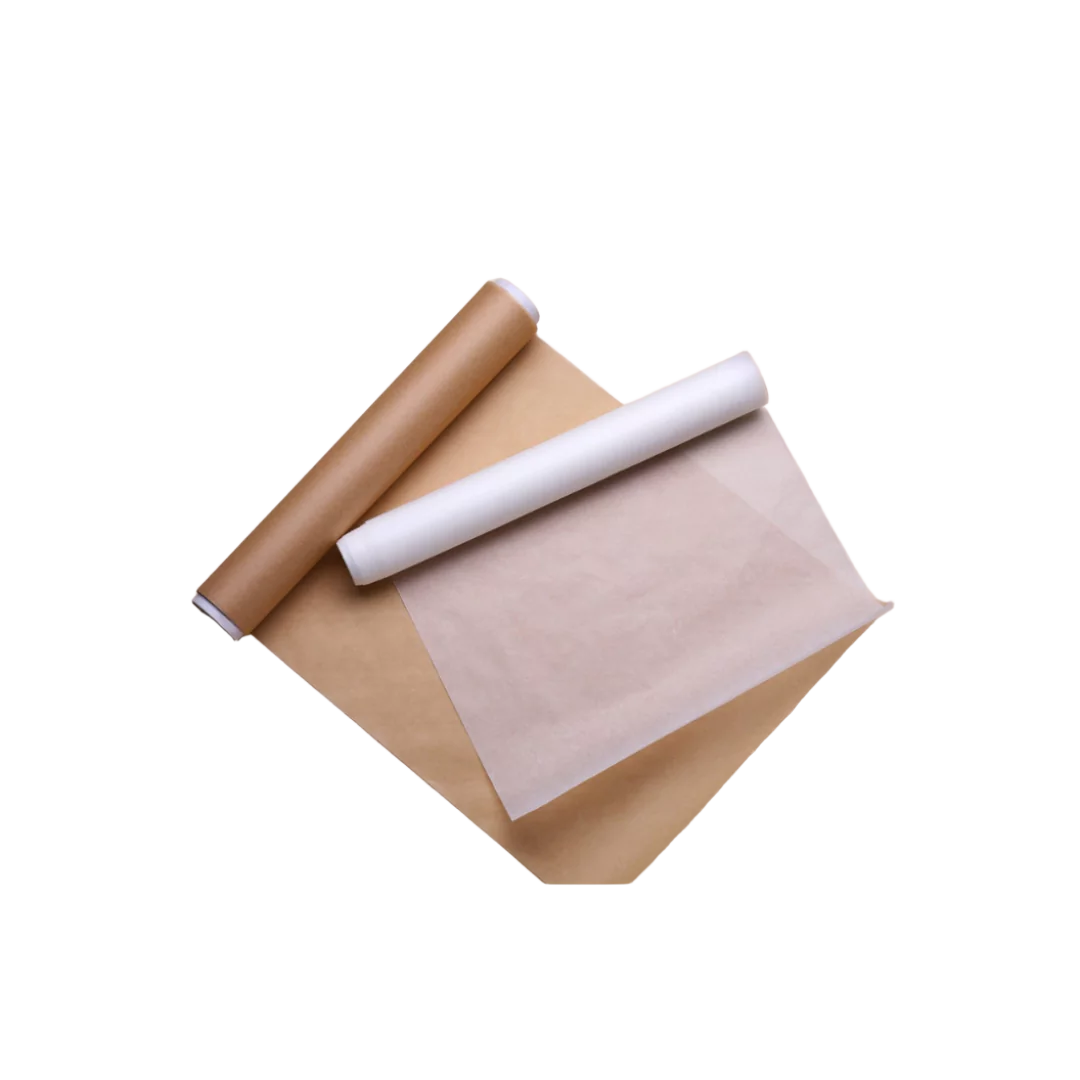

Branded Food Paper

Make your brand part of every meal with our Branded Food Paper — the perfect blend of functionality and visual identity. This custom-printed, food-safe paper gives cafés, takeaways, and restaurants the chance to wrap every order in a signature look. Whether it’s a simple logo or bold full-colour design, your brand gets front-row visibility with every customer served.

Crafted for direct food contact, the grease-resistant paper keeps burgers, sandwiches, and wraps fresh while promoting your brand at every touchpoint. Choose from natural kraft or bright white sheets depending on your aesthetic, and we’ll handle the rest — custom sizes, fast turnaround, and vibrant results. Ideal for growing businesses or national chains, our personalised food packaging offers both low MOQs and wholesale. From street food vendors to luxury catering, it’s how smart brands stay remembered. Build recognition with every wrap — print your branded food paper and serve packaging that speaks for you.

Starting From: £0.50 Per Box

Available in Stock

Q. What’s the difference between branded food paper and generic food wraps?

Q. What type of ink is used for printing on branded food paper?

Q. Is branded food paper suitable for direct contact with hot food?

Q. Can you customise both the paper size and print design?

Q. Does the ink stay intact with greasy or saucy foods?

Q. Can branded food wraps be used for both dine-in and takeaway?

Q. Are eco-friendly or recyclable options available for branded food wrap?

Q. What’s the typical minimum order for custom branded food sheets?

Q. How long does it take to produce and deliver custom food wrap paper?

Q. Can branding be printed on both sides of the paper?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.