| Type | Specification |

|---|---|

| Material | Wax-Coated Food-Grade Paper |

| GSM Range | Customisable 24–40 GSM (Most Used: 28, 32 GSM) |

| Sizes Available | Standard: 6×6″, 8×8″, 10×10″ – Custom Sizes On Request |

| Wax Coating | Single-Sided, Double-Sided, or Spot Wax Coating |

| Grease Resistance | High Oil Barrier – Ideal for Buttery & Oily Cookies |

| Printing | Edge-to-Edge or Pattern Repeat Custom Logo Print |

| Print Colour | CMYK, Pantone (PMS), Metallic Ink Options |

| Base Paper Colour | White, Kraft Brown, Black, or Custom-Dyed Sheets |

| Food Compatibility | Cookies, Brownies, Pastries, Bars, Donuts |

| Coating Material | Paraffin Wax, Soy Wax, or Custom Vegan Wax |

| Texture Finish | Silky Smooth, Soft Gloss, or Semi-Translucent Look |

| Ink Type | Food-Safe, Water-Based, Odourless Inks |

| Heat Resistance | Up to 60°C – Suitable for Warm but Not Hot Items |

| Freezing Suitability | Yes – Maintains Flexibility Without Cracking |

| Biodegradability | Eco-Friendly, Compostable, and Recyclable |

| MOQ | As Low As 1,000 Sheets with Custom Printing |

| Packing Options | Flat Pack, Kraft-Wrapped Reams, or Shrink-Wrapped |

| Cut Format | Die-Cut Sheets, Rolls, or Perforated Tear Sheets |

| Certifications | FDA Approved, FSC Paper, ISO Food Safety Certified |

| Sampling | Free Branded Wax Sheet Sample on Request |

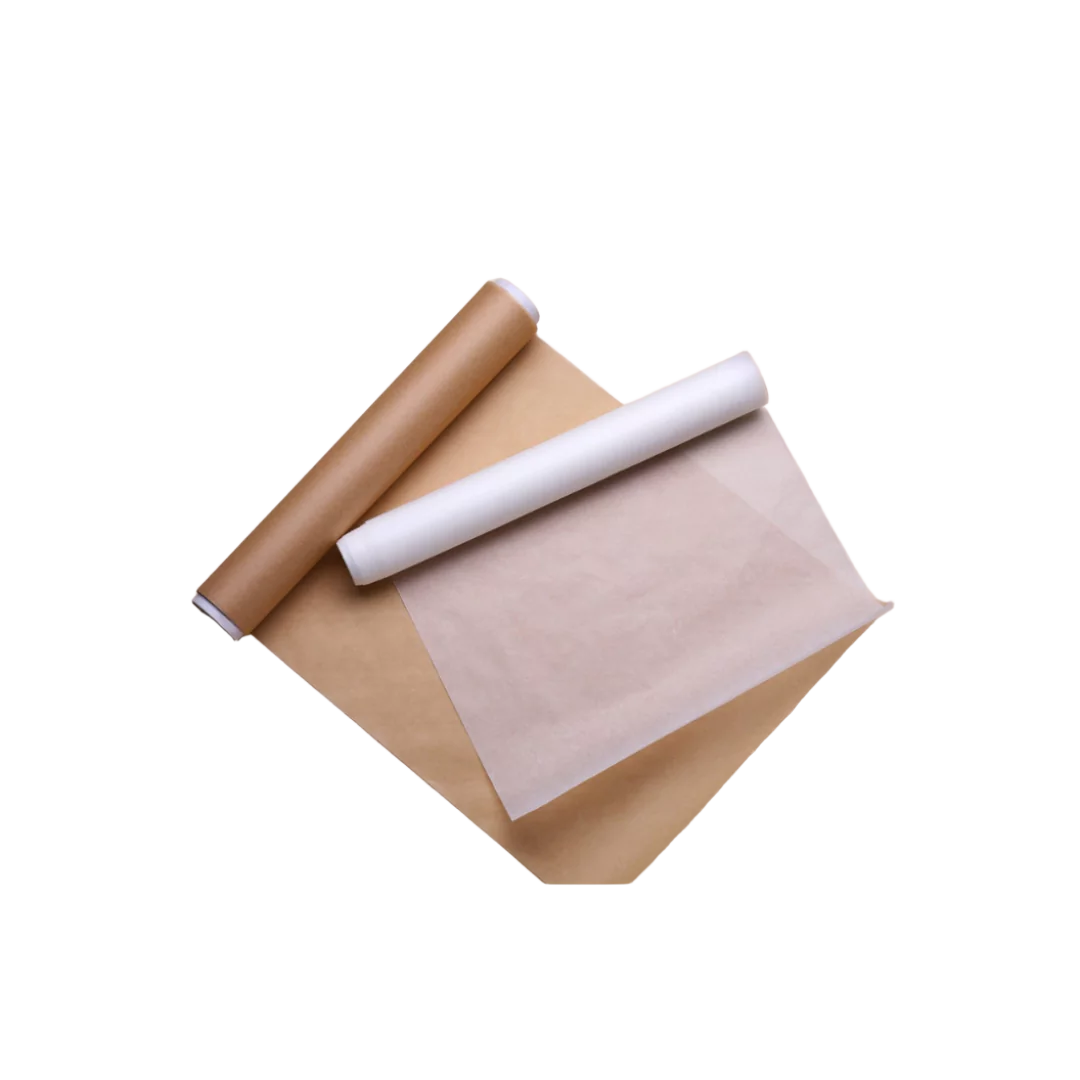

Cookie Wax Paper

Baking perfection starts with the right foundation. Our premium cookie wax paper creates the ideal non-stick surface that releases cookies effortlessly while preventing burnt bottoms and uneven baking. Professional bakers and home enthusiasts discover the difference quality wax paper makes in achieving consistent results batch after batch. Double-sided wax coating provides superior heat resistance and moisture protection, ensuring cookies maintain their intended texture from oven to display case. The silky smooth surface eliminates the need for additional greasing, saving time during busy baking schedules while producing cleaner, more professional results.

Available in commercial roll sizes for bakeries managing high-volume production or convenient pre-cut sheets perfect for home baking projects. Custom printed food paper featuring your bakery logo transforms ordinary packaging into premium presentation that customers remember. Wholesale pricing makes professional-grade wax paper surprisingly affordable, while bulk orders ensure you never run short during peak baking seasons. Food-safe certification guarantees peace of mind for both commercial and personal use.

Starting From: £0.50 Per Box

Available in Stock

Q. What type of wax paper works best for wrapping cookies?

Q. Does wax paper keep cookies fresh during transport?

Q. Can cookie wax paper be custom printed with designs or logos?

Q. Is wax paper safe for direct contact with edible items like cookies?

Q. Can wax paper be used to separate stacked cookies?

Q. Is cookie wax paper heat-resistant for baking use?

Q. What sizes are best for wrapping or lining cookie packaging?

Q. Is wax paper recyclable or eco-friendly for cookie packaging?

Q. Will wax paper affect the icing or decoration on cookies?

Q. Can wax paper be used to line cookie tins or favour bags?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.