| Type | Specification |

|---|---|

| Box Style | Corrugated Pillow Box – Side Flaps Auto-Lock or Tuck-In |

| Material | E-Flute, B-Flute, or Double Wall Corrugated Cardboard with Kraft or White Liner |

| Printing Methods | Flexographic, Offset, Digital (CMYK & PMS) |

| Colour Options | Custom Solid Colours, Full Colour, Spot UV, Inside & Outside Print |

| Logo Placement | Front Panel, Side Flaps, Interior – Fully Customisable |

| Standard Sizes | Small (4×3″), Medium (6×4″), Large (9×5″) – Custom Sizes Available |

| Thickness | 1.5mm – 4mm Corrugated Board Options |

| Quantity | Minimum 50 Units – Bulk Production Available |

| Window Option | Optional PET or PVC Die-Cut Window |

| Finish | Gloss, Matte, Aqueous, Soft-Touch, or No Coating |

| Inserts | Custom Corrugated, Cardboard, Kraft, or Foam Inserts on Request |

| Closure | Tuck-In Flap or Auto Lock, Optional Security Tape Strip |

| Eco-Friendly | Recyclable Board, FSC® Certified Paper, Soy-Based Inks |

| Usage | Retail Packaging, E-commerce, Gifts, Apparel, Promotional |

| Production Time | 7–12 Business Days (Rush Orders Available) |

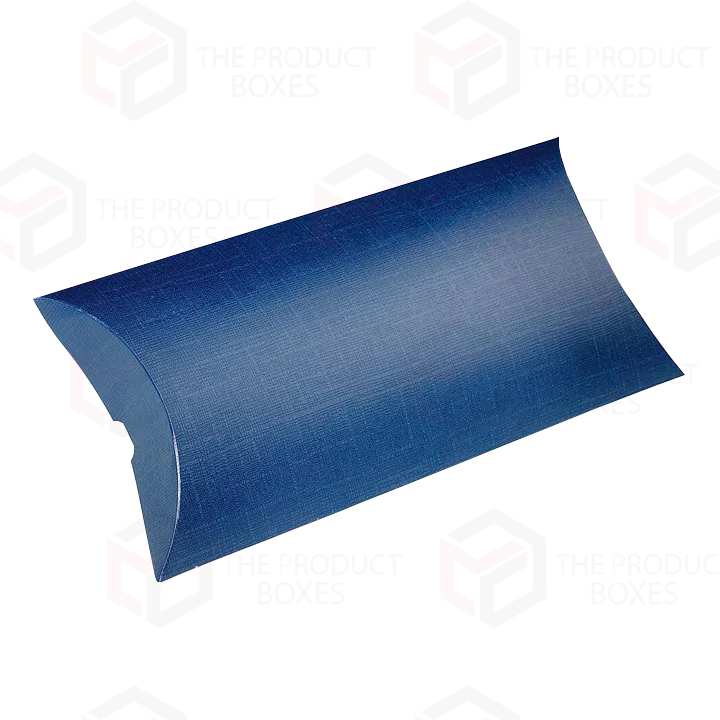

Corrugated Pillow Boxes

Corrugated pillow boxes are designed with the appealing curve of regular pillow shape packaging but are much durable. These boxes are suitable for sending or showing off cosmetics, accessories, clothing items and promotional merchandise. With the strength and safety of corrugated material, personalised pillow boxes are well-suited for gift and retail purposes. At The Product Boxes UK, you can design your own custom product boxes, selecting the size, print, colours and finishes that best match your brand.

Add your logo or a message to the packing materials to motivate customers and show who you are. Putting these boxes together and shipping them doesn’t add bulk or weight. Regardless of if your products are displayed in stores or shipped directly to buyers, corrugated boxes provide a good-looking, easy-to-handle and safe packaging solution. You can order any volume, knowing that pillow boxes wholesale uk option is available.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Corrugated Pillow Boxes?

Q. Are Corrugated Pillow Boxes customisable in size?

Q. Can I add my logo and branding on Corrugated Pillow Boxes?

Q. Are these boxes suitable for shipping or retail display?

Q. What finishes can be applied to Corrugated Pillow Boxes?

Q. Can inserts be added inside these pillow boxes?

Q. Are window options available for Corrugated Pillow Boxes?

Q. Are Corrugated Pillow Boxes eco-friendly?

Q. What is the minimum order quantity for these boxes?

Q. Can I get interior printing or custom messages inside the box?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.