| Type | Specification |

|---|---|

| Material | High-quality corrugated cardboard, rigid board, Kraft paper, SBS paperboard |

| Printing Options | CMYK, PMS, digital, offset, screen printing |

| Finishing | Matte, gloss, spot UV, soft-touch lamination, foil stamping, embossing, debossing |

| Thickness | 12pt, 14pt, 16pt, 18pt, 24pt, or custom |

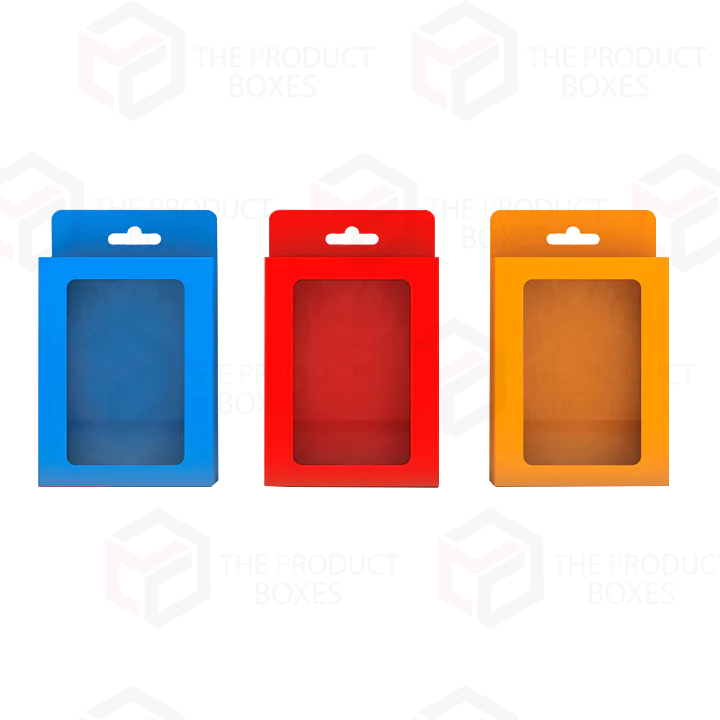

| Customization | Full custom sizes, shapes, inserts, partitions, window cutouts, die-cut designs |

| Logo & Branding | Custom logo printing, embossing, debossing, metallic foil stamping, UV spot |

| Color Options | Pantone, RGB, CMYK, full-color or monochrome printing |

| Structural Integrity | Impact-resistant, shock-absorbent, tamper-proof, reinforced corners |

| Coatings | Aqueous, anti-scratch, gloss/matte lamination, grease-resistant |

| Sizes | Standard and custom dimensions available |

| Closure Type | Magnetic closure, tuck-end, auto-lock bottom, snap-lock, friction-fit |

| Eco-Friendliness | 100% recyclable, biodegradable, FSC-certified materials |

| Applications | Electronics, mobile accessories, gadgets, PC components, smart devices |

| Minimum Order Quantity | 100 pieces |

| Production Time | 7-12 business days, express service available |

| Shipping Options | Flat-packed or pre-assembled |

Custom Electronic Products Boxes

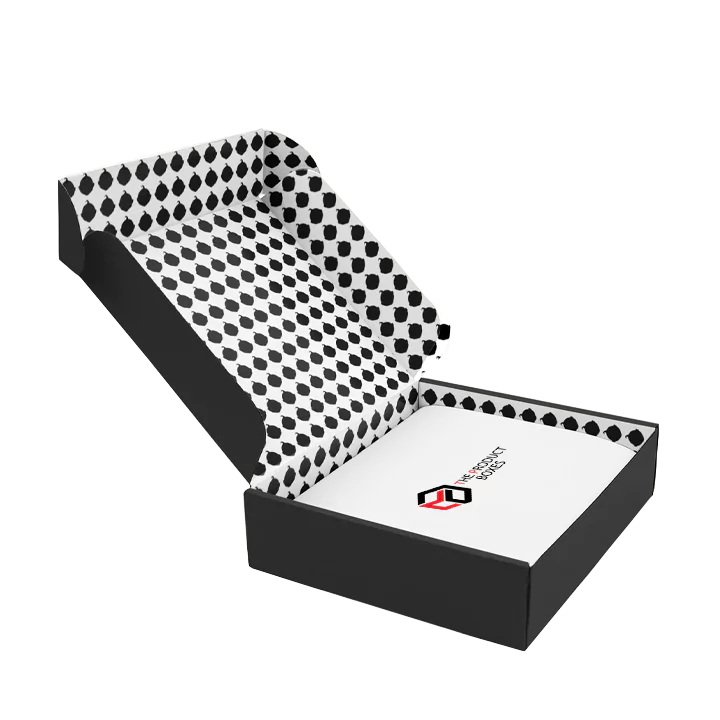

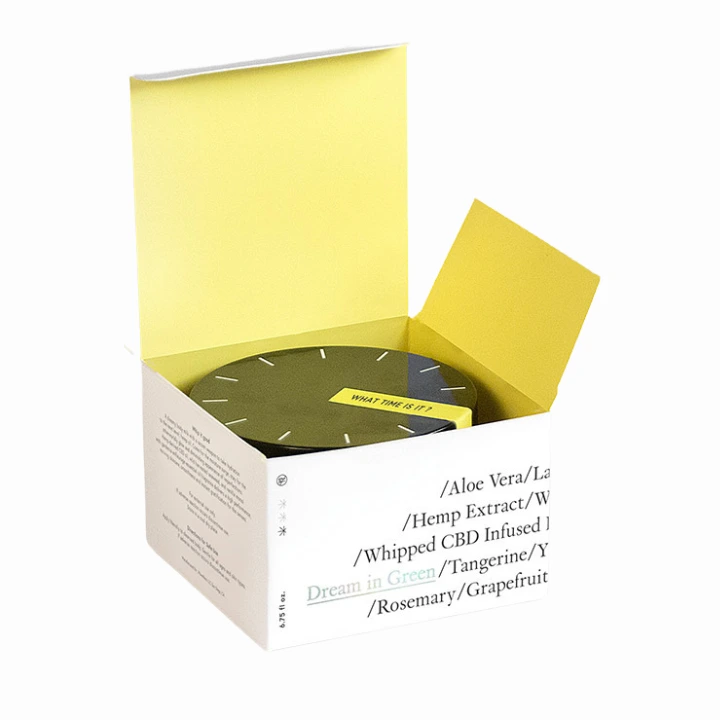

Protect and showcase your electronics with highly durable custom electronic products boxes created to leave an impression on your brand. These boxes ensure professional packaging, shock resistance, and a sophisticated appearance for mobile accessories, headphone, smart devices, and home appliance products. At The Product Boxes, we provide tailor made electronic product packaging solutions using rigid boxes, corrugated box packaging, foam inserts, custom die cut packaging, and other options.

Your brand identity can be made with different finishes, embossing, foil stamping, UV coating or high-end prints. Our small product packaging boxes are also designed to protect against dust, moisture, and damage during transit. We also provide highly cost-effective wholesale custom electronic product boxes of premium quality for your large scale needs. Make your customer’s unboxing experience extraordinary with custom packaging boxes. Get in touch with The Product Boxes today for top of the line electronic packaging solutions.

Starting From: £0.80 Per Box

Available in Stock

Q. What materials are used to make Custom Electronic Product Boxes?

Q. Can I get Custom Electronic Product Boxes in different sizes and shapes?

Q. What printing options are available for Custom Electronic Product Boxes?

Q. Are Custom Electronic Product Boxes eco-friendly?

Q. Can I add branding elements like logos and product details on the boxes?

Q. Do you provide protective coatings for electronic packaging?

Q. What closure styles are available for Custom Electronic Product Boxes?

Q. How can I ensure my electronic products are safe inside the packaging?

Q. What is the minimum order quantity for Custom Electronic Product Boxes?

Q. What is the production and delivery time for Custom Electronic Product Boxes?

Q. Do you provide flat-packed or pre-assembled shipping for electronic boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.