| Type | Specification |

|---|---|

| Dimensions | Standard sizes from 3” x 4” to 12” x 15” or custom sizes upon request |

| Printing | CMYK, PMS, Digital Printing, or No Printing |

| Material | High-Quality Mylar, Aluminium Foil, Clear or Opaque Layers |

| Thickness | Customisable from 2 mil to 6 mil depending on product requirements |

| Closure Options | Ziplock, Heat-Sealed, Tear Notch, or Child-Resistant Closures |

| Coating | Gloss, Matte, or Holographic Finishes |

| Default Process | Die Cutting, Laminating, Sealing, Pouching |

| Options | Custom Printing, Window Panels, Hang Holes, or Odour-Proof Layers |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 6-8 Business Days, Rush Orders Available |

| Material & Colour Options | Unlimited colours and eco-friendly materials available |

| Shipping | Free Shipping Across the UK, International Shipping Available |

Custom Printed Mylar Bags

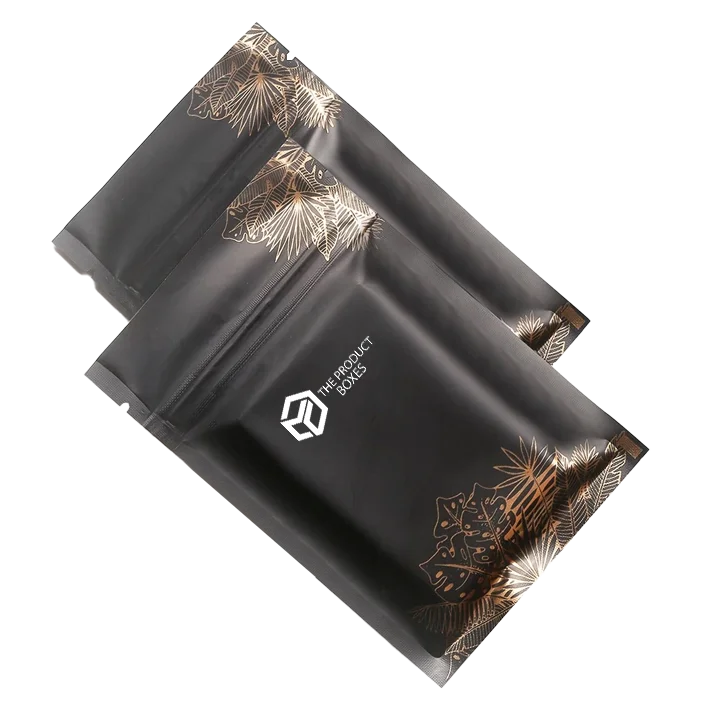

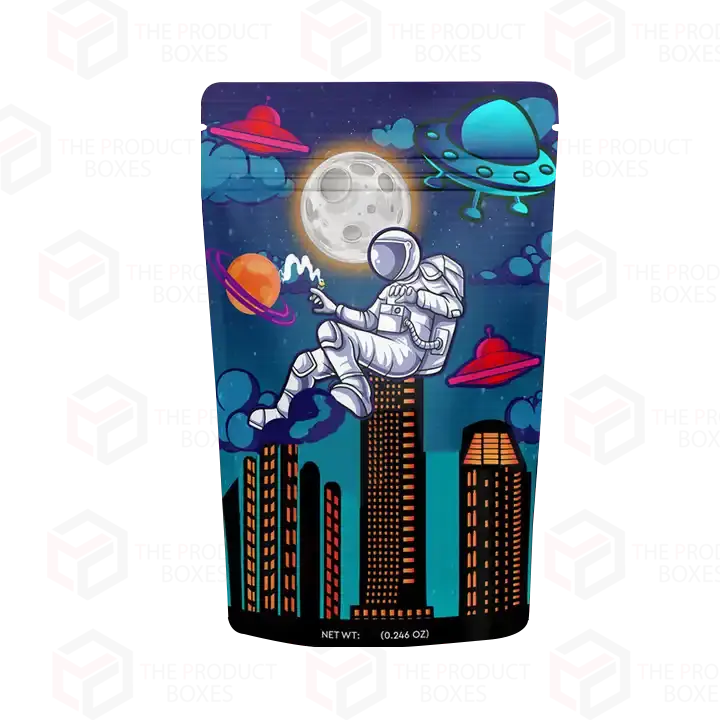

If you are looking for durable and versatile packaging solutions from food items to beauty products, custom printed mylar bags offered by The product boxes UK are the best. These mylar bags with oxygen absorbers are famous for their great ability to protect the content from air, light and moisture. You can design your own mylar bags with custom prints to elevate the overall branding and create a professional appearance according to the customers demand. Whether you need a mylar bag wholesale in the food industry or selling supplements, these bags are available in multiple sizes and requirements.

We offer multiple types of finishes like matter, glow or clear to compliment the branding elements. Print your logo, graphics or special message. Moreover, our customisation option also includes window cut-outs or foil stamping to increase the visual appeal of the product inside. Our mylar bags are not just stylish but also functional and ensure that the product stays safe inside. So, if you are a business owner and looking for the best place to buy mylar bags uk, contact us today and make a lasting impression on your customers.

Starting From: £0.30 Per Box

Available in Stock

Q. Can I customise the design on Mylar bags?

Q. What sizes are available for custom Mylar bags?

Q. Are the Mylar bags suitable for food storage?

Q. Do you offer different closure options for Mylar bags?

Q. Can I add a window to the Mylar bags?

Q. What materials are used in your Mylar bags?

Q. How long does it take to produce custom Mylar bags?

Q. Can I get a proof before production?

Q. Are the Mylar bags eco-friendly?

Q. What is the minimum order quantity for custom Mylar bags?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.