| Type | Specification |

|---|---|

| Material | Kraft paper, rigid board, cardboard, corrugated, eco-friendly recycled paper |

| Printing | CMYK, PMS, digital, offset, UV printing, soy-based ink |

| Customization | Fully customizable in size, shape, and design |

| Finishing | Gloss, matte, soft-touch, spot UV, foil stamping, embossing, debossing |

| Closure Type | Slip lid, push-up, magnetic closure, twist-top, sealed ends |

| Inner Lining | Food-grade coating, aluminum foil, velvet, EVA foam, cardboard insert |

| Window Options | Custom die-cut, PVC, biodegradable film |

| Logo & Branding | Embossed, debossed, foil stamped, UV spot printed, screen printed |

| Sizes | Custom diameters and heights available |

| Eco-Friendly | 100% recyclable, biodegradable, FSC-certified materials |

| Usage | Cosmetics, food items, tea, coffee, candles, apparel, gifts |

| MOQ | 100 units minimum order quantity |

| Production Time | 7-10 business days, varies with customization |

| Shipping | Worldwide shipping, flat or assembled delivery options |

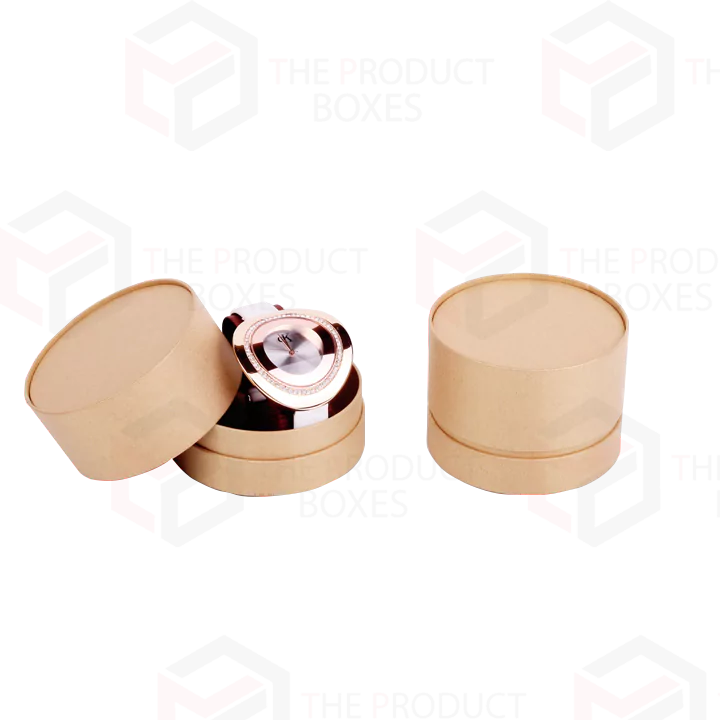

Custom Printed Tube Packaging

Custom printed tube packaging from The Product Boxes UK delivers durable packaging that conveys elegance and brand recognition. The cylindrical boxes represent a superior packaging solution as well as effectively for cosmetics, candles, food products and luxury gifts. The tube’s packaging showcases products effectively while providing security during storage and shipping logistics. Our team at The Product Boxes provides premium-quality cardboard tube packaging that can easily be customised through full-colour printing, embossing, foil stamping, custom inserts or matte/gloss finishes that create impact at unboxing time.

Among our wide range of tube boxes, we provide multiple dimensions to match diverse product specifications. Product boxes London offers wholesale custom printed product packaging options that deliver low-cost solutions without compromising product quality for bulk purchase requirements. Appeal to your audience through brand-enhancing tube packaging that combines sustainability and personalised design elements. Contact us today for high-quality tube packaging that will match your brand identity precisely.

Starting From: £0.80 Per Box

Available in Stock

Q. What materials are used to make Custom Printed Tube Packaging?

Q. Can I customize the size and shape of Custom Printed Tube Packaging?

Q. Are Custom Printed Tube Packaging options eco-friendly?

Q. What printing options are available for Custom Printed Tube Packaging?

Q. Can I add a transparent window to Custom Printed Tube Packaging?

Q. What finishing options are available for Custom Printed Tube Packaging?

Q. What closure types are available for Custom Printed Tube Packaging?

Q. Can I add my logo and branding to Custom Printed Tube Packaging?

Q. What are the common uses of Custom Printed Tube Packaging?

Q. Do you offer wholesale or bulk orders for Custom Printed Tube Packaging?

Q. How long does it take to manufacture Custom Printed Tube Packaging?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.