| Type | Specification |

|---|---|

| Material | Kraft, White Cardboard, Recyclable Board, PE-Lined Paperboard |

| Structure | Die-Cut Lock Tab Design with Rear Ventilation Slits |

| Printing | CMYK, Pantone, Digital, Offset |

| Logo | Custom Printed (Foil Stamp, Embossed, Debossed, UV Spot Available) |

| Colour Options | Natural Brown, Black, White, Full Custom Colour Match |

| Window Option | With/Without PLA Transparent Window |

| Coating | Gloss, Matte, AQ Coating, Food-Safe Lamination |

| Sizes | Standard: 5″x5″, 6″x6″, 7″x7″ | Custom Dimensions Available |

| Box Style | Triangular Wedge, Clamshell, Hinged Lid, Foldable Flat |

| Printing Finish | UV Coating, Soft-Touch Lamination, Raised Ink |

| Usage | Cold Sandwiches, Wraps, Paninis, Deli Items |

| Quantity | Minimum Order 500 Units | Bulk & Wholesale Options |

| Customisation | Shape, Size, Logo, Colour, Window Cut, Finishing |

| Eco Options | Compostable, Biodegradable, FSC Certified |

| Delivery Format | Flat-Packed or Pre-Assembled |

| Lead Time | 7-12 Business Days (Custom Orders May Vary) |

Empty Sandwich Boxes

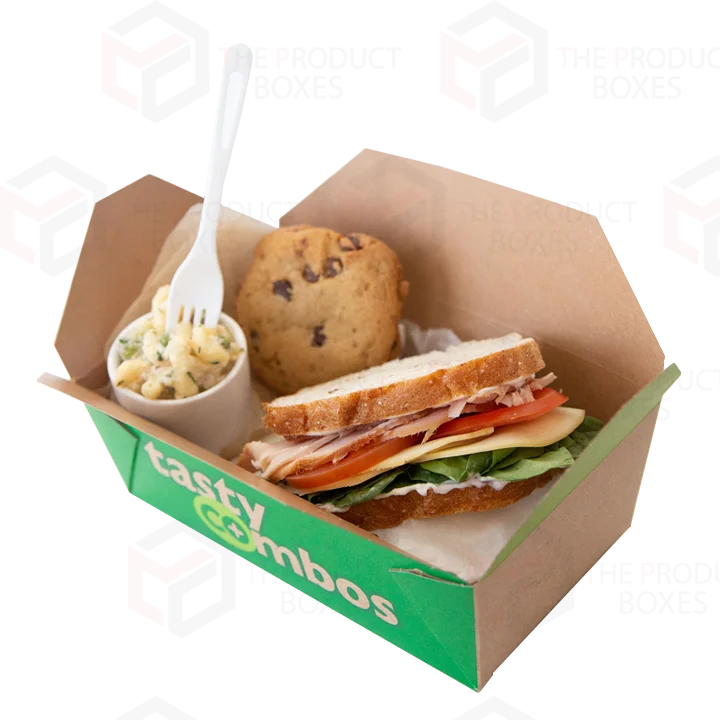

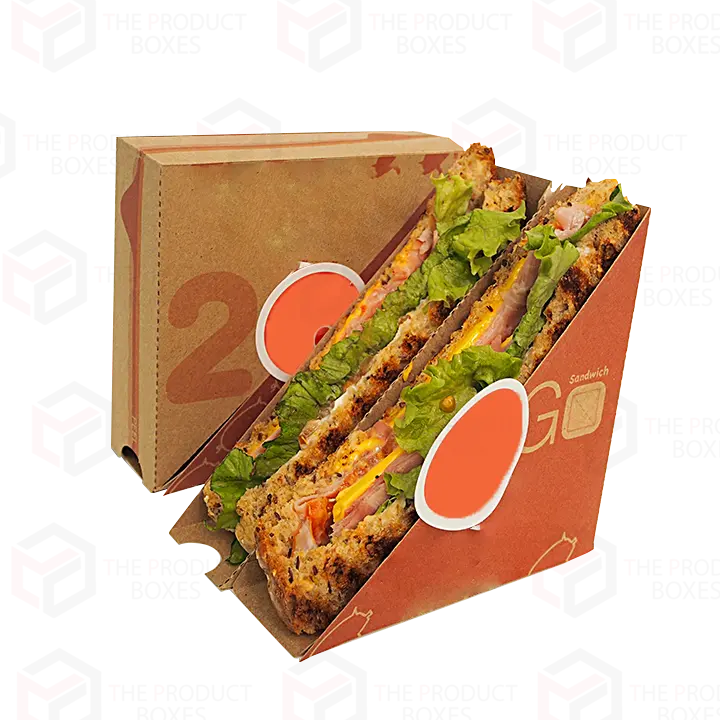

The empty sandwich boxes designed by TPB provide convenience, style and hygiene features for keeping sandwiches fresh and well-presented. This versatile food packaging suits cafes, delis, takeout shops, catering businesses, and meal prep brands to contain their whole range of subs and panini varieties. As part of our product line, The Product Boxes delivers durable food-safe sandwich boxes to customers through kraft, cardboard, or recyclable paperboard materials. The empty boxes are suitable for branding for the businesses to display their logos, taglines along with exclusive artwork.

Your business can decide between open or complete enclosed boxes for different functions. You have options to choose the triangle sandwich packaging, boxes in wedge, flat and clamshell patterns with multiple dimensions and shapes. Our professional team at The Product Boxes offers complete customisation services with different design choices on empty cardboard food boxes. Need to stock up? Reach out for wholesale prices on blank sandwich boxes as we want to help maintain optimal business operations. Contact us now to create innovative sandwich boxes with a modern brand impression.

Starting From: £0.39 Per Box

Available in Stock

Q. What materials are used to make Empty Sandwich Boxes?

Q. Can I get custom sizes for my sandwich packaging?

Q. Are these boxes suitable for hot sandwiches?

Q. Can I add a transparent window to my sandwich boxes?

Q. What printing options are available?

Q. Are the boxes eco-friendly and recyclable?

Q. How are the boxes shipped—flat or assembled?

Q. What is the minimum order quantity (MOQ)?

Q. Can I print my logo or brand on the sandwich boxes?

Q. How long does production and delivery take?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.