| Type | Specification |

|---|---|

| Material | Premium cardboard, kraft paper, corrugated board, and rigid stock |

| Printing | CMYK, PMS, digital, and offset printing with high-resolution graphics |

| Coating | Gloss, matte, spot UV, soft-touch, and aqueous coating |

| Size | Custom sizes available as per requirement |

| Shape | Square, rectangular, gable, window-cut, and custom shapes |

| Closure | Tuck-end, magnetic closure, ribbon tie, and auto-lock |

| Window Option | Die-cut window with PVC or transparent sheet |

| Finishing | Embossing, debossing, foil stamping, UV spot, and lamination |

| Branding | Custom logo printing, hot foil stamping, and UV spot branding |

| Quantity | Available in small to bulk orders (custom wholesale options) |

| Eco-Friendly | Made from recyclable and biodegradable materials |

| Production Time | 7-10 business days (depending on order size and customization) |

| Usage | Ideal for packaging fudge, chocolates, candies, and sweet gifts |

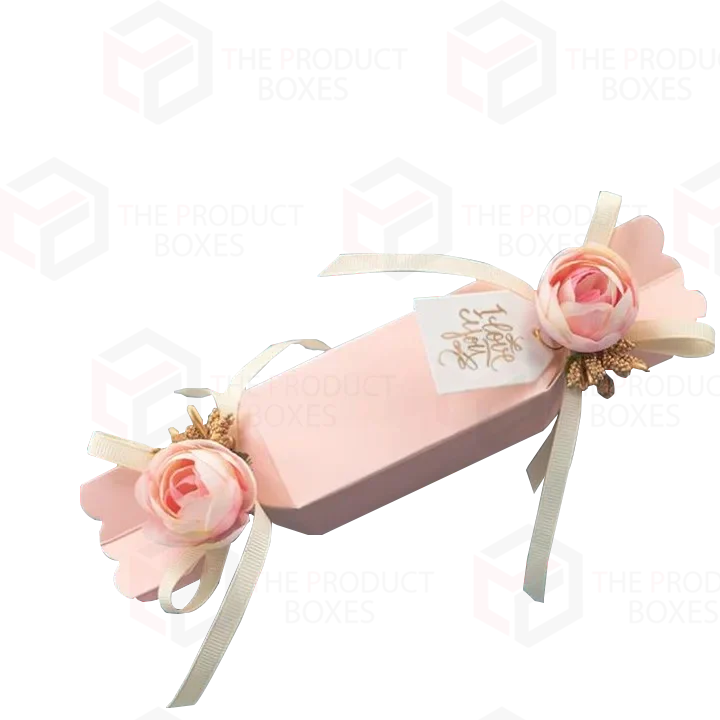

Fudge Favour Boxes

Fudge favour boxes enhance the presentation of fudge gifts for weddings, birthdays, corporate events and special parties. These boxes present fudge with secure packaging that also provides a stylish look which enhances any special event. Advanced cardboard and kraft and rigid materials form these boxes deliver durability and superior quality appearance. Customers can request customised sweet favour boxes at The Product Boxes UK.

We’ve multiple options for favour boxes such as dimensions, surface decorations with features and finishing effects which deliver an elegant look. Customise your fudge packaging with company logos with messages and event-related designs to match with your celebration theme. TPB offers favour boxes wholesale option to facilitate bulk orders by delivering top-quality design at affordable pricing. So, contact us today and enhance your fudge gifts by selecting attractive packaging designs. Get customised fudge favour boxes for your upcoming celebration.

Starting From: £0.80 Per Box

Available in Stock

Q. What materials are used to make Fudge Favour Boxes?

Q. Can I order Fudge Favour Boxes in custom sizes and shapes?

Q. Are Fudge Favour Boxes eco-friendly?

Q. Do you offer custom printing on Fudge Favour Boxes?

Q. What finishing and coating options are available for Fudge Favour Boxes?

Q. Can I add a transparent window to my Fudge Favour Boxes?

Q. What closure types are available for Fudge Favour Boxes?

Q. Do you offer wholesale or bulk orders for Fudge Favour Boxes?

Q. Can I add my brand logo to the Fudge Favour Boxes?

Q. How long does it take to produce custom Fudge Favour Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.