| Type | Specification |

|---|---|

| Material | Eco-friendly kraft paper, cardboard, and coated paper |

| Color | Green (Matte, Glossy, Metallic, Textured Finishes Available) |

| Printing Options | CMYK, PMS, UV, Digital, Embossing, Foil Stamping |

| Custom Branding | Logo Printing, Custom Artwork, Full-Color Printing |

| Size | Small (4x3x1 inches), Medium (6x4x2 inches), Large (9x6x3 inches) – Custom Sizes Available |

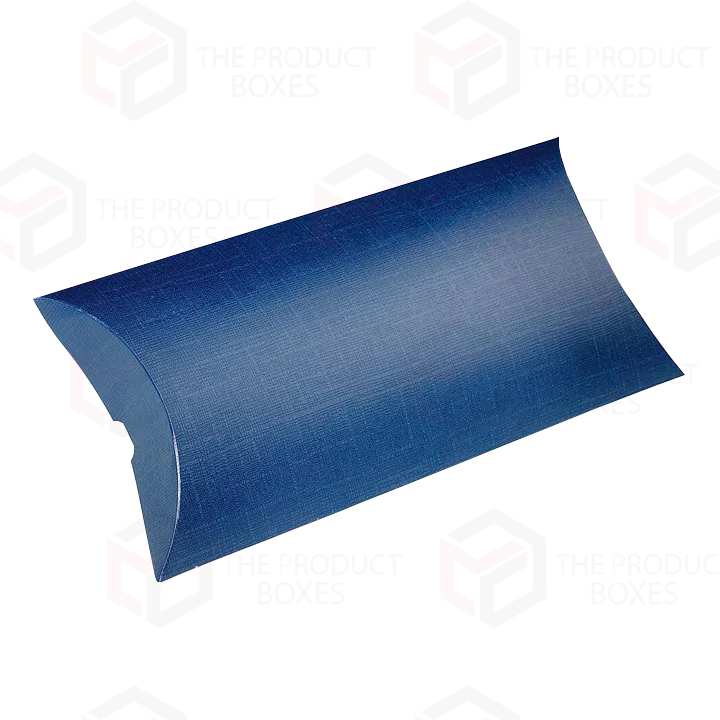

| Shape | Pillow-Style with Curved Flaps |

| Surface Finish | Matte, Glossy, Soft-Touch, Spot UV, Aqueous Coating |

| Quantity | Low MOQ, Bulk Orders Available |

| Closure Type | Foldable Flaps, Tuck Ends, Adhesive Sealing Available |

| Usage | Gift Packaging, Retail Products, Jewelry, Cosmetics, Favors |

| Eco-Friendliness | 100% Recyclable, Biodegradable, Sustainable Packaging |

| Additional Features | Window Cut-Out, Die-Cut Handles, Custom Inserts Available |

| Production Time | 7-10 Business Days (Rush Orders Available) |

| Shipping | Flat-Packed for Easy Storage, Global Shipping Available |

Green Pillow Boxes

The usage of green pillow boxes brings sophistication and environmental-friendliness for presenting gifts and retail items. These convenient packaging boxes possess a stylish curved appearance which produces an attractive visual effect. Pillow boxes work best for jewellery items, cosmetics, tiny accessories and party favours because of their elegant styling and lightweight qualities. Our company, The Product Boxes provides a range of custom pillow boxes with logo available in different dimensions, colours variations and finishing options.

The branding elements become visible through printing services in order to optimise your branding. The pillow box packaging includes eco-friendly material such as cardboard, high-quality kraft paper to ensure both durability and sustainability. Our pillow box packaging wholesale offer includes bulk green pillow boxes that deliver superior quality at affordable rates. Stylish and eco-conscious boxes are a perfect way to enhance your packaging needs. Contact The Product Boxes to build unique packaging boxes that will enhance your brand image during events.

Starting From: £0.50 Per Box

Available in Stock

Q. What materials are used to make Green Pillow Boxes?

Q. Can I customize the size and shape of Green Pillow Boxes?

Q. What printing options are available for Green Pillow Boxes?

Q. Are Green Pillow Boxes eco-friendly?

Q. What are Green Pillow Boxes commonly used for?

Q. Can I add a window cut-out to my Green Pillow Boxes?

Q. Do Green Pillow Boxes come in different finishes?

Q. What is the minimum order quantity (MOQ) for Green Pillow Boxes?

Q. How are Green Pillow Boxes shipped?

Q. What is the production time for custom Green Pillow Boxes?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.