| Type | Specification |

|---|---|

| Material Composition | Premium Food-Grade Cupboard, 300–450 GSM with Dual Insulation Layers |

| Wall Structure | Double Wall & Triple Wall Ripple Construction for Maximum Heat Retention |

| Insulation Technology | Air-Gap Thermal Barrier, Ripple-Texture Heat Shield, Anti-Condensation Inner Lining |

| Available Sizes | 8 oz, 10 oz, 12 oz, 14 oz, 16 oz, 20 oz — custom volume options available |

| Base Colours | White, Natural Kraft, Pantone-Matched Solid Colours, Custom Print Backgrounds |

| Branding & Logos | Full-Wrap Branding, High-Def Logo Print, Multi-Colour Artwork, QR Code Integration |

| Printing Techniques | Offset, UV Offset, Flexographic Print, Digital Short-Run Customisation |

| Surface Finishes | Matte, Gloss, Soft-Touch Lamination, Textured Ripple Outer Shell |

| Coating Options | PE Single/Double Lining, PLA Compostable Coating, Water-Based Barrier Film |

| Heat Tolerance | Withstands Hot Beverages up to 98°C with Anti-Scald Grip Surface |

| Lid Compatibility | Secure Fit 80mm & 90mm Lids — Dome, Flat, and Sip-Lock Designs |

| Leak Prevention | Pressure-Sealed Sidewalls, Reinforced Bottom Seal, Anti-Leak Rim Curl |

| Logo Enhancement Effects | Spot UV, Metallic Foiling, Raised UV, Embossed Ripple Texture Highlight |

| Customisation Options | Brand-Themed Series, Seasonal Prints, Multi-Design Packaging Sets |

| Eco-Friendly Variants | PLA Biodegradable Cups, Recyclable Board, Water-Based Ink System |

| Quantity Options | Custom Sleeves of 25 or 50; Bulk Cartons From 500–1000+ Units |

| Rim Structure | Thick Rolled Rim for Superior Lid Interlock & Spill Resistance |

| Certifications | FDA Approved, BPA-Free, EU 1935/2004 Food Safety Compliance |

| Applications | Coffee Shops, Cafés, Corporate Chains, Events, High-Temperature Beverage Service |

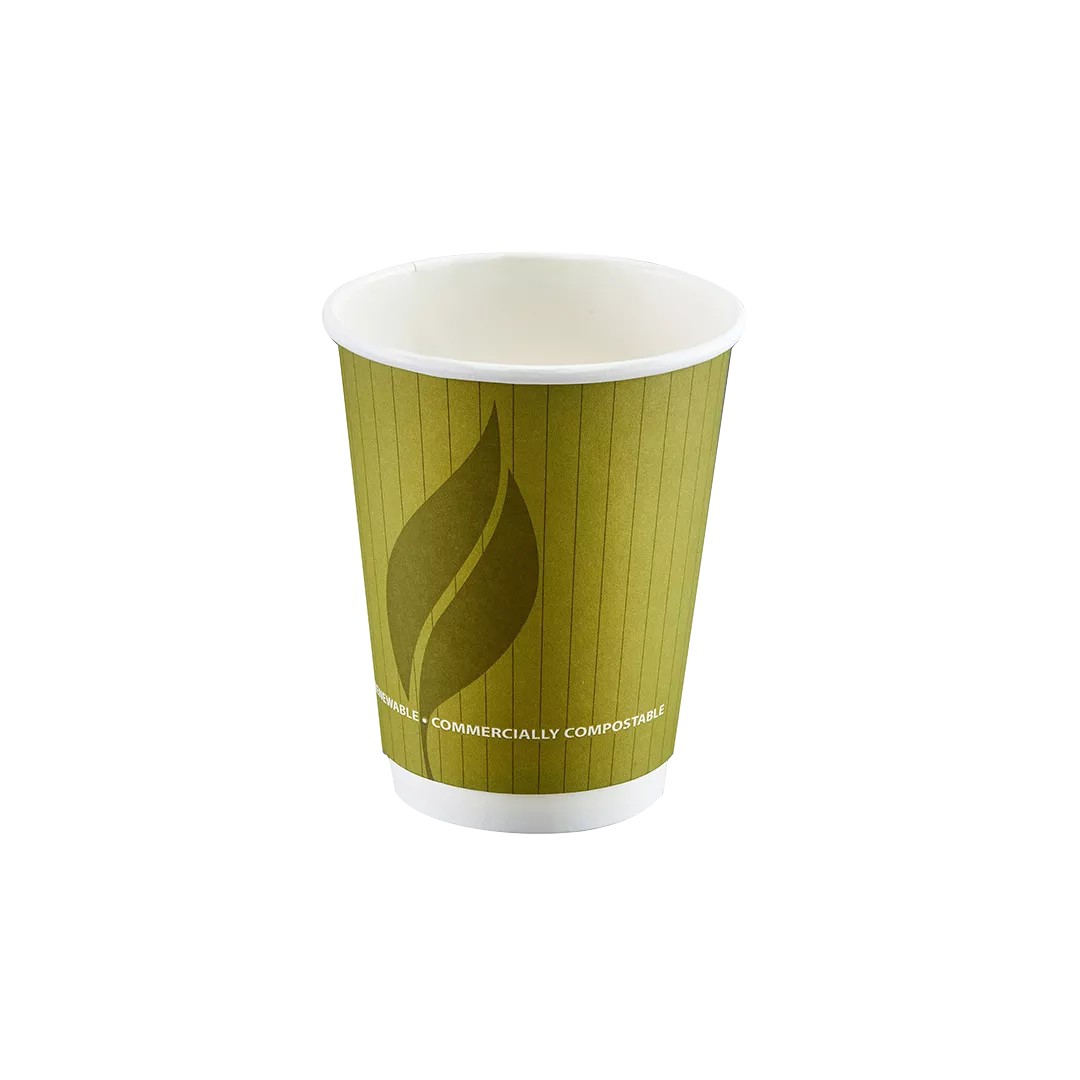

insulated Paper Cups

Protect customer hands from burns while keeping beverages hot with insulated paper cups featuring double-wall construction. The air gap between inner and outer walls provides thermal barrier that eliminates the need for separate sleeves, reducing your per-serving packaging costs and simplifying inventory management. These cups handle boiling liquids without transferring heat to the exterior surface, meaning customers can comfortably hold their coffee from counter to car without juggling or pain. The double-wall structure also adds rigidity that prevents crushing when gripped firmly. Available in standard hot beverage sizes from 8oz to 16oz with textured outer walls for secure grip.

Coffee shops prefer insulated cups because they enhance the premium drinking experience that justifies higher menu prices. Custom printed cups works beautifully on the exterior surface with your branding. The Product Boxes supplies them in wholesale quantities with competitive pricing that offsets the slightly higher per-unit cost compared to single-wall versions. Stock plain for immediate use or order custom branded versions with three-week lead times. Biodegradable options available.

Starting From: £0.93 Per Box

Available in Stock

Q: How does double-wall construction improve heat retention in insulated paper cups?

Q: Which insulation designs reduce condensation for cold beverages?

Q: How does cup thickness affect stacking and storage?

Q: Are embossed or textured surfaces beneficial for insulated cups?

Q: How can personalised branding be applied without affecting insulation?

Q: What lid types complement insulated cups for takeaway beverages?

Q: How do eco-friendly linings influence insulation performance?

Q: How does the cup base design affect stability for hot drinks?

Q: Can insulated cups be used for layered beverages like lattes or iced frappes?

Q: How do finishing options enhance user experience with insulated cups?

Get an instant quote

Related Products

Corrugated

Cardboard

Kraft

Rigid

Holographic

Offset Print

Digital Print

UV Print

Pantone

Hot Foil Stamping

Cold Foil Stamping

Blind Embossing

Blind Debossing

Registered Embossing

Combination Embossing

Window Patching

Aqueous Coating

UV Coating

Spot Gloss UV

Soft Touch Coating

Varnish

Lamination

A very thin plastic film is pasted in the boxes to make them more durable and long-lasting.